Video

1 / 1

full Automatic UVLED bucket barrel screen printing machine

$125000.00

≥1 Set/Sets

Model:

- SZD-1023B

| Model No. : | SZD-1023B |

|---|---|

| Brand Name : | KC |

| Type of printing plate : | Screen Printer |

Dongguan, Guangdong, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- The Belt And Road

Product description

Samples

Plastic barrels with a diameter of more than 200mm are widely used in product packaging, such as: lubricating oil, coatings, paint, atomic ash, they are usually made of PP and PE are made of plastic. Printing such a plastic barrel must use a specially designed large -scale automatic screen printer, which is the enlarged design of the container screen printing machine.

Plastic barrel screen printers have roughly the same structure and ordinary dragon screen printer:

1) Feeding conveyor belt: it is a conveyor belt. The operator can put the bucket on the conveyor belt. The conveyor belt can automatically transfer the plastic barrel to the suction position, and the nozzle of the machine will suck the plastic barrel into the transmission table of the screen printing machine. In order to reduce artificially as possible, it is also a trend to use robots to place plastic barrels on the transmission belt.

2) Flame treatment: In order to improve the adhesion of the polyolefin material, the machine also configures the flame treatment head to treat its surface.

3) Silk printing system: The screen printing system of the automatic screen printing machine adopts plastic barrel rotation, and the screen plate of the movement form. In order to improve the printing efficiency and accuracy, the left and right movement of the screen plate can be controlled by a servo motor. The pneumatic components use a well -known international brand. Essence The main structure of the machine is welded with steel plates, which is more durable.

4) UV drying system: For continuous high -speed silk screen printing, the important choice to ensure that the screen plate is not blocked is to use ultraviolet ink. UV ink can only dry under UV light. High characteristics.

5) Uninstallation system: The printed products will be placed on the conveyor belt in an orderly manner for quality testing.

The fully automatic plastic barrel screen printer is generally composed of the host and several monochrome printed machines, which can be connected into two colors, three colors, four colors, five colors, six colors.

Description

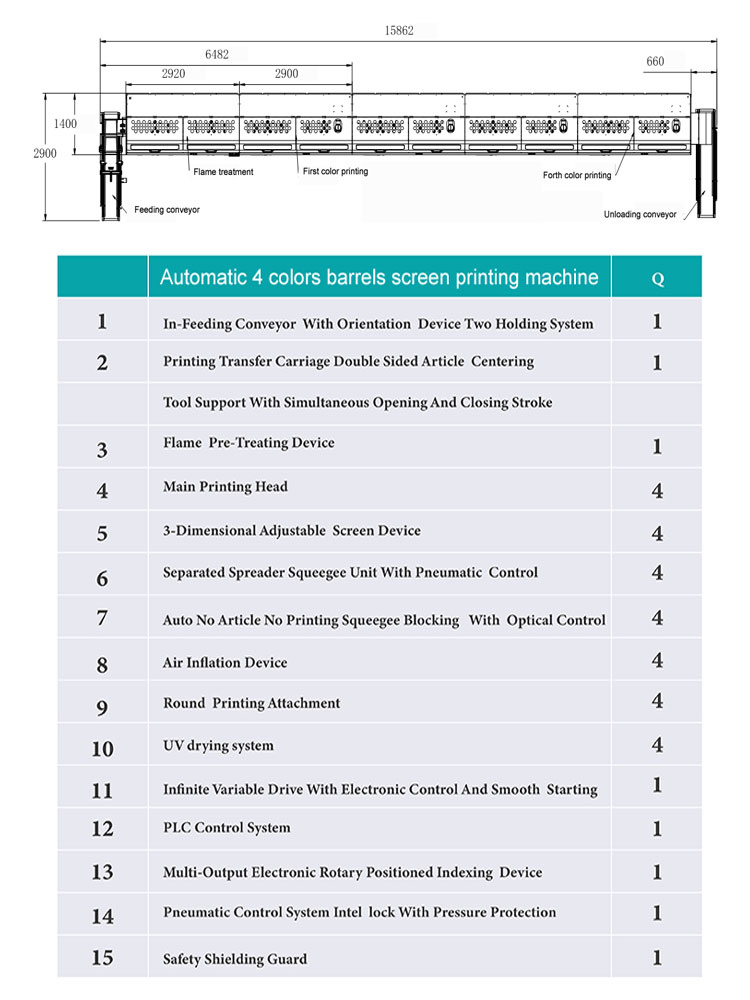

SZD-1023B Full automatically screen printing Machine//Parameter

1.Max printing size: 1100x250mm

2.Min printing diameter Ф150mm

3.Max printing diameter: Ф350mm

4.Min bucket height: 200mm

5.Max bucket height: 400mm

6.Power supply: 380V 50Hz

7. Compress air supply : 5-7 kg/cm²

8. Max screen plate size: 1200x400mm

9. Max printing speed 1500pcs/hr

10. Machine wattage: 16 KW

11. Machine weight: 4000kg

SZD-1023B full automatically screen printing machine//Advantage

2. Automatic and continuous flame surface treatment system.

3. The round bottle pre -positioning and two -way opening -closing -closing mechanism printing systems, monitoring no access and no printing functions.

4. Adjustable bottle passing device.

5. US high -efficiency UV light curing system.

6.2 meters long finished product inspection conveyor belt.

7. Independent PLC program controller and easy -to -use touch screen operation control system.

8. Adopt world -renowned brand electrical components to ensure the lasting stability and durability of the machine.

Catalogue

Install size

Video

Dongguan, Guangdong, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- The Belt And Road

Send your inquiry to this supplier