Video

1 / 4

YHZS25 concrete batching plant with compact structure

Model:

- HZS25 export to Algeria

productivity:

- 25m³/h

Options:

- Power:18.5Kw

- Discharging Height:3.8m

- Aggregate:≤80mm

| Model No. : | HZS25 export to Algeria |

|---|---|

| Brand Name : | SIMAMIX |

| Applicable industry : | Other,Machinery Repair Shops |

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Product description

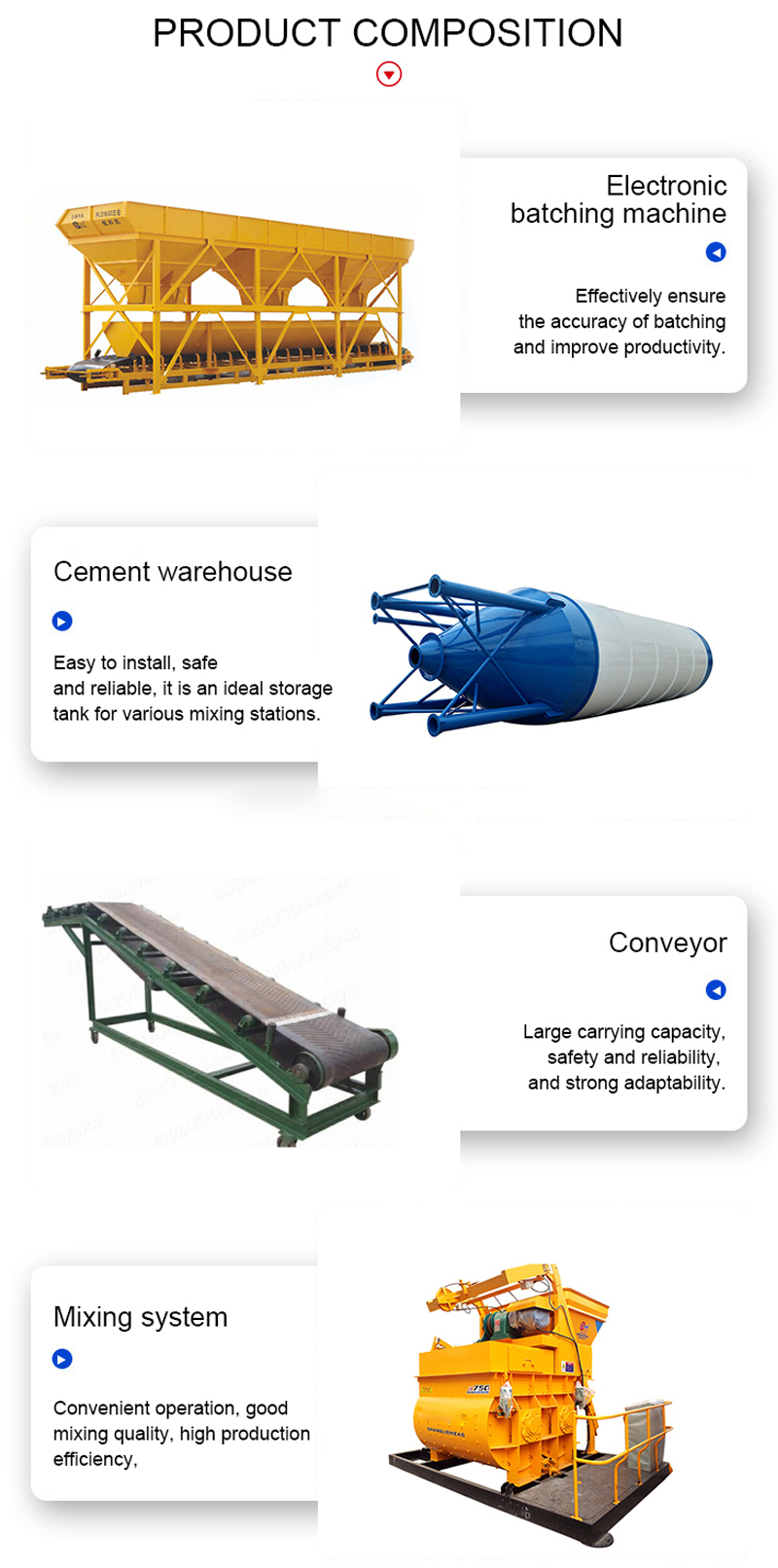

The HZS concrete batching plant is an advanced and sophisticated technology that is also known as a concrete mixing station. This high-tech equipment incorporates several essential features such as the horizontal twin-shaft compulsory concrete mixer, cement silo, screw conveyor, concrete batching machine, belt conveyor or skip hopper, and a control room. It is capable of producing various types of concretes, including plastic and dry hard concrete, with ease, owing to its exceptional efficiency and functionality. The HZS concrete batching plant is widely used in large and medium-sized building constructions, precast plants, and road and bridge constructions due to its quick mixing, easy operation, and superior production efficiency. It is undoubtedly the most preferred option for commercial concrete production, and its popularity is continuously on the rise.

HZS concrete batching plant is also called concrete mixing plant, concrete mixing station. It includes horizontal twin-shaft compulsory concrete mixer, concrete batching machine, cement silo and screw conveyor, belt conveyor or skip hopper, and control room. It can produce a variety of concretes, such as plastic, dry hard concrete with high production efficiency, short mixing time, and easy operation. HZS concrete batching plant is widely used in large and medium-sized building construction, road and bridge, and precast plants. It is the ideal plant for the production of commercial concrete.

This product Low cost mini concrete batching plant for sale is equipped with the storage, batching, conveying, stirring, control and other devices of various raw materials required for precast concrete, and various aggregates, powders, admixtures, water, etc.A complete set of equipment for supplying concrete in a concentrated manner than by a mixer.

1.The overall steel structure of the concrete mixing station is made of high-quality steel, which has high overall structural strength and strong stability.

2.The mimi concrete mixer machine adopts the twin-shaft forced mixing main machine, which has strong mixing performance, uniform mixing and high productivity.

3.Excellent pneumatic components, electrical components, etc.; to ensure the reliability of the equipment, accurate metering performance.

4.Each maintenance and repair site is provided with a walking platform or a check ladder, and has sufficient operation space. Easy maintenance and repair.

Features

Main Configuration

After-Sales Service

◆ Guarantee time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

◆ Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

◆ Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

◆ Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

Packing & Delivery

Raw Material

Some Questions You Care About:

Q: What details should be paid attention to in the operation and construction of concrete mixing plant?

1. The operator of the concrete mixing plant must be certified. It is strictly forbidden to hand over the concrete machinery to undocumented personnel for operation. In the process of operation, pay attention to correct operation and do not leave the job without authorization.

2. Before the operation of the concrete mixing plant, check the clamps, clutches, brakes, pulleys, steel wire ropes, transmission devices, upper limit of the hopper, electrical circuits, protective neutral or grounding wires, etc. Any abnormalities must be eliminated.

3. If there is a multi-shift system, the shift system should be implemented conscientiously and the work records after the shift should be kept.

4. The machinery must be used reasonably in accordance with the specified technical performance.

5. After the upper hopper is raised, it is strictly forbidden to enter under the hopper. When cleaning the lower part of the hopper, the safety chain must be hung. When someone enters the mixing drum for cleaning and maintenance, unplug the isolating switch in the switch box and lock the switch box to avoid injury caused by misoperation.

6. After the operation is completed, the machine should be cleaned up, the power supply should be cut off, and the switch box should be locked.

Q:How to improve the production efficiency of the concrete mixing plant?

1. According to the production capacity of the civil commercial concrete mixing station and the distance of the finished product transportation, line and road conditions, Equipped with a sufficient number of carriers, Generally 1.2 times the required productivity;

2.Factors affecting the productivity of concrete mixer equipment, In addition to the two direct factors of mixing time and time utilization factor. There are also some relevant factors, Such as production organization, management and operation quality of equipment, the technical condition of equipment operation, the preparation of raw materials and transportation vehicles also have an obvious role in ensuring and improving productivity;

3.Strengthen the maintenance and management of equipment in commercial concrete mixing station. Ensure that the equipment is in a good technical condition, and meets the requirements of the environmental protection law, establish a strict maintenance and testing system and preventive measures, do timely repair;

4.In order not to stop the commercial concrete mixing station equipment due to special reasons, there shall be a finished material storage warehouse with sufficient capacity;

Q:The advantages of concrete mixing plant application

1.performance is very stable

Concrete mixing plant in the process of operation has more stable performance, can ensure better standards in work efficiency, professional stability and low carbon environmental protection use advantages in full play, especially the use of more high-end production and processing technology for research and development design, naturally meet the application of a kinds of different environment, naturally will bring better use experience

2.uses higher security

y using professional production of mixing station work, have better advantages in safety, especially in maintenance will be more cost saving, production capacity will be stronger, will bring higher cost performance, avoid too much manpower and maintenance in the process of material resources and time, reasonable cost in terms of cost control.

3.works more efficiently

Have more stable work performance, especially in the process of operation has a safer use effect, important is to have more specifications and models, naturally in operation will have better advantages, to ensure the efficiency can improve the quality of work, so let the work stability is stronger, bring more worry use experience.

FAQ:

Q: How about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. Chinese top brands or world grade brands like Siemens motors etc are equiped.

Q: How about the price?

A: As a manufactory, we can give you lower price than trade companies.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.It usually takes 1-3 days for training , 10-15 days for installation,1-2days for commission,1-2days for pre-operation.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training.It’s about 90-120 usd a day.

Q: How long it takes to do all the installation

A: It’s at most 5days processing and manufacturing for single machine,for production line,at most 15days.

Q: Can we visit your factory?

A: Yes. You can visit our factory at anytime you want.

Video

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier