1 / 4

YGKJ560 Automatic Lubrication Biomass Pellet Mill

| Model No. : | YGKJ560 |

|---|---|

| Brand Name : | ROTEXMASTER |

| Type : | Flat Die Platen Wheel |

Product description

>Products Introduction of Wood Pellet Machine:

♦ YGKJ series vertical ring die pellet machine absorbed the essence of pellet mill in oversea market,after our engineers improved,it had reached the international advanced level.

♦ The heart parts [double layer die" has unique structural assembly and [rollers" are made of high quality wear resistant alloy steel.These two parts have the following characters: particular design, reasonable structure, low energy, high efficiency, long service life and so on.

♦ YGKJ series verticaol ring die pellet machine is mainly applicable for difficult molding materials with low adhesion rate, for example rice husk, sunflower husk, peanut shell and fruit shell; branch, stem, rind and other wood waste; a variety of crop stalks; rubber, cement, ash and other chemical materials. It can be used in feed mill, wood processing plants, fuel plants, fertilizer plants, chemical plants etc.

♦ Less investment,Fast return,No risk.

YGKJ series efficient vertical ring die pellet machine is an ideal dense

>Advantages of Wood Pellet Machine:

Vertical hopper: This design can avoid the raw material be stuck in granulating room

Cooling system: As the pelletizing process will generate high temperature, it will lower the service life of die and bearing. Cooling system are considering this situation and avoid it happened

Double-layer dies: This design increase the efficiency of pellet making, reduce clients cost

Siemens frequency conversion motor: Sweden famous brand.

SKF bearing: Sweden famous brand, High precision, high speed, low noise, long life

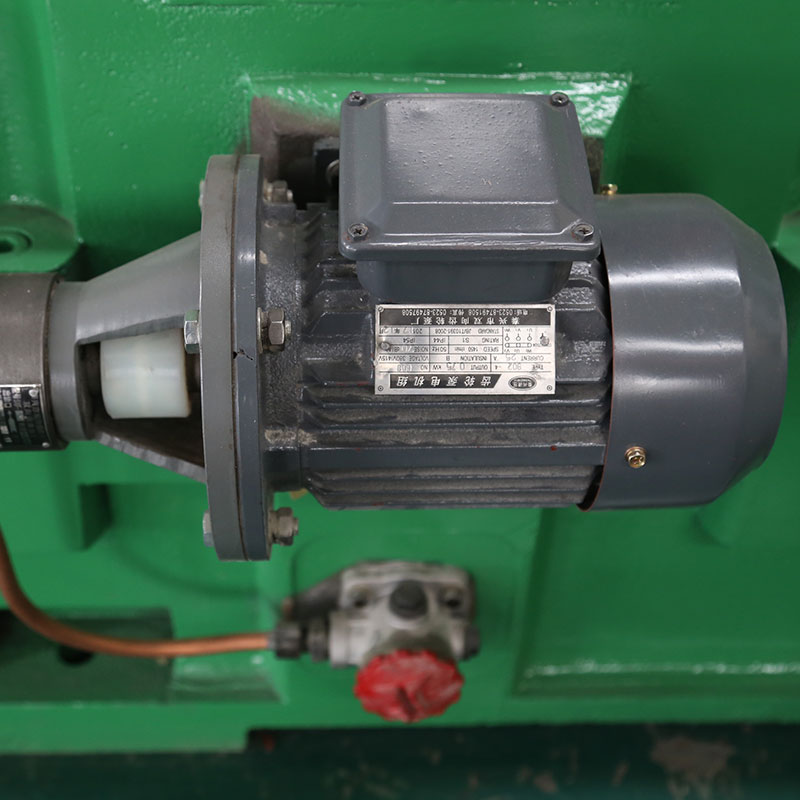

Unique automatic lubricating system: Which lubricate the bearing, dies and rollers, increase the produce efficiency and reduce energy consumption. It can work continuous 20 hours.

>Technical Parameters of Wood Pellet Machine:

>After-sales Service:

Caring service, carefully manufacture and desirable price make customers at ease.

"Customer-oriented": providing customers with whole considerate services;

"Service as core": providing the most suitable products to customers;

"Quality-centered":All-round services to every customers!

"Technical support":on-site technical training and technical advice available.

>Picture Show of Wood Pellet Machine:

Main spare parts of wood pellet machine

If you are interested in our products, please contact me

Send your inquiry to this supplier