Video

1 / 4

Y30BH Injection molding ferrite magnet for washing machine

$0.02

≥10000 Piece/Pieces

$0.20

≥100000 Piece/Pieces

Options:

- 9*10.5MM

- 9*15MM

- 12*18MM

- 13.5*21MM

- 16*25MM

- 18*30MM

- 19*30MM

| Model No. : | 19*30mm |

|---|---|

| Brand Name : | YB |

| place of origin : | China |

Zhuzhou, Hunan, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

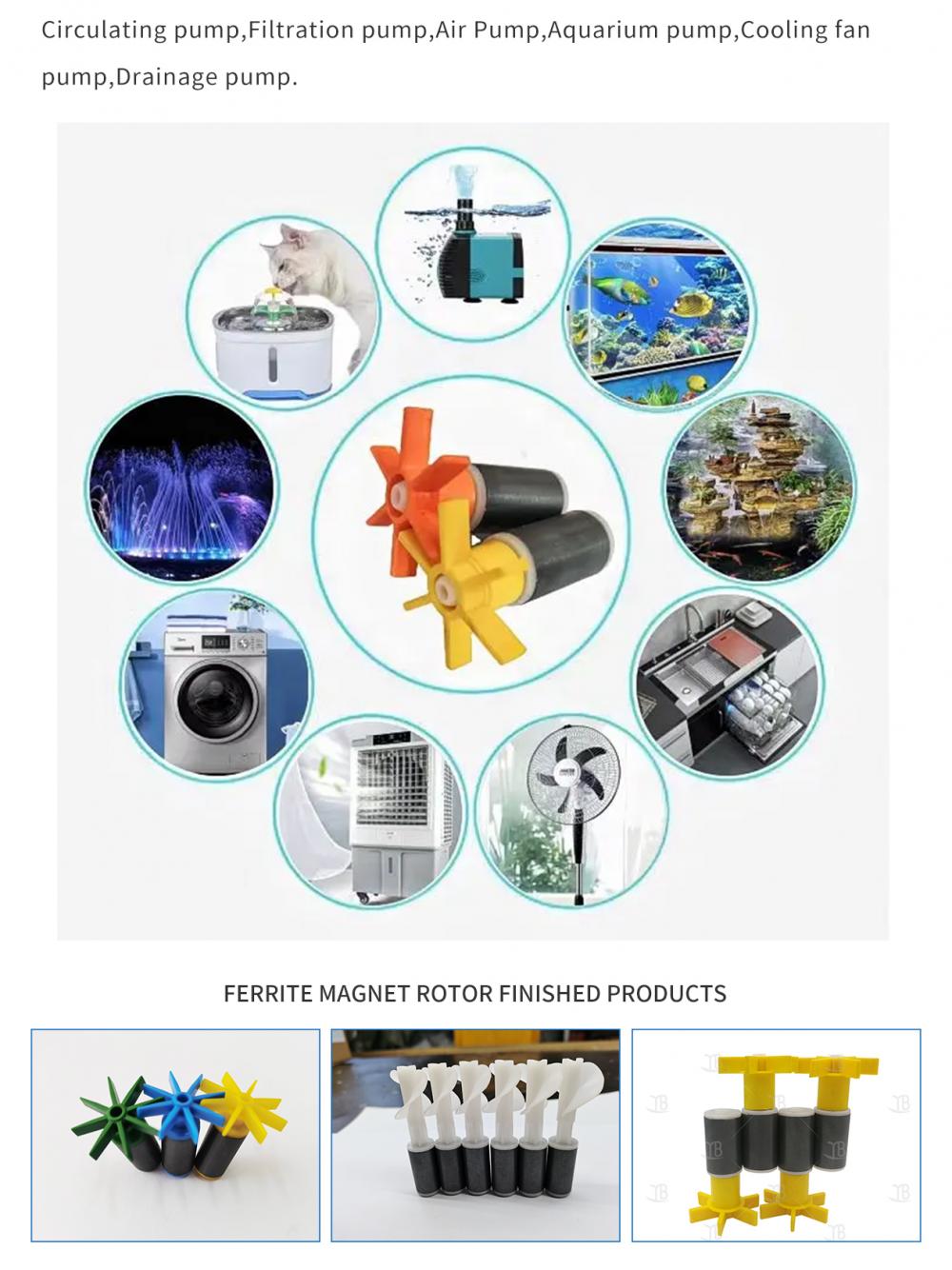

What's ferrite magnet rotor?

Anisotropic Ferrite Magnet Rotor parts

1. Impeller: This is the rotating component of the pump that creates the flow of coolant through the system.

2. Housing: This is the casing that contains the impeller and the other components of the pump.

3. Shaft: This is the component that connects the impeller to the motor of the pump.

4. Bearings: These are the components that support the shaft and allow it to rotate smoothly.

5. Seals: These are the components that prevent coolant from leaking out of the pump.

6. Motor: This is the component that provides the power to rotate the impeller.

7. Capacitor: This component provides the necessary boost to the motor to start it up.

8. Control circuit: This is the electronic circuit that controls the operation of the pump.

9. Power cord: This is the cord that connects the pump to the power supply.

10. Inlet and outlet fittings: These are the components that connect the pump to the cooling system.

Water Pump Rotor Magnet, Barium Ferrite Magnets, Anisotropic Ferrite Magnet Rotor, Cooler Water Pump Magnet

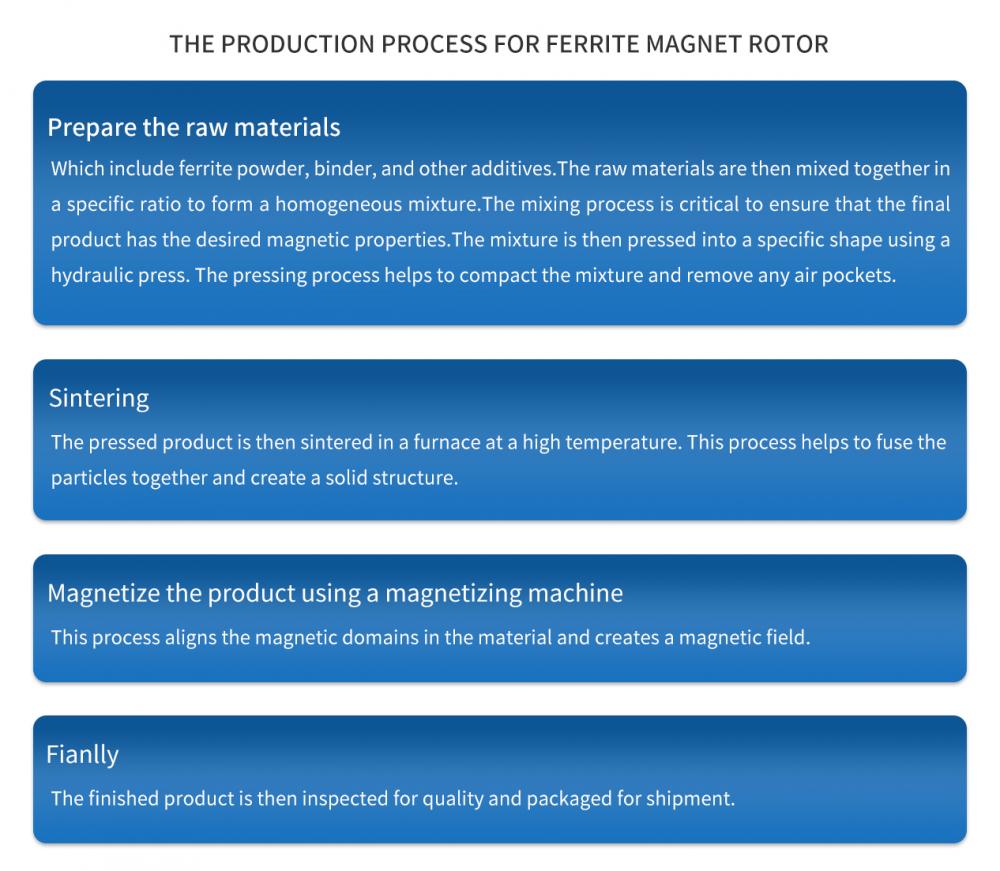

The production process of a ferrite magnet rotor involves the following steps:

1. Mixing: The raw materials, which include iron oxide, barium carbonate, and strontium carbonate, are mixed in a ball mill to form a homogeneous mixture.

2. Pressing: The mixture is then pressed into the desired shape using a hydraulic press. The pressing process helps to compact the mixture and remove any air pockets.

3. Sintering: The pressed parts are then sintered in a furnace at high temperature (around 1200°C) for several hours. During this process, the mixture is transformed into a hard and dense material.

4. Machining: The sintered parts are then machined to the desired shape and size using a diamond cutting tool. This process ensures that the parts have a smooth surface and precise dimensions.

5. Coating: The finished parts are then coated with a protective layer to prevent corrosion and improve their durability.

6. Magnetization: The final step is to magnetize the parts using a magnetizing machine. This process aligns the magnetic domains in the material, giving it magnetic properties.

Once the ferrite magnet rotor is complete, it can be used in various applications, including electric motors, generators, and magnetic couplings.

Video

Zhuzhou, Hunan, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier