Video

1 / 6

XCC ZXZ ball bearing elevator

| Model No. : | elevator bearing |

|---|---|

| Brand Name : | ZXZ |

| Type : | Control System |

Shaoxing, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

ZXZ ball bearing elevator

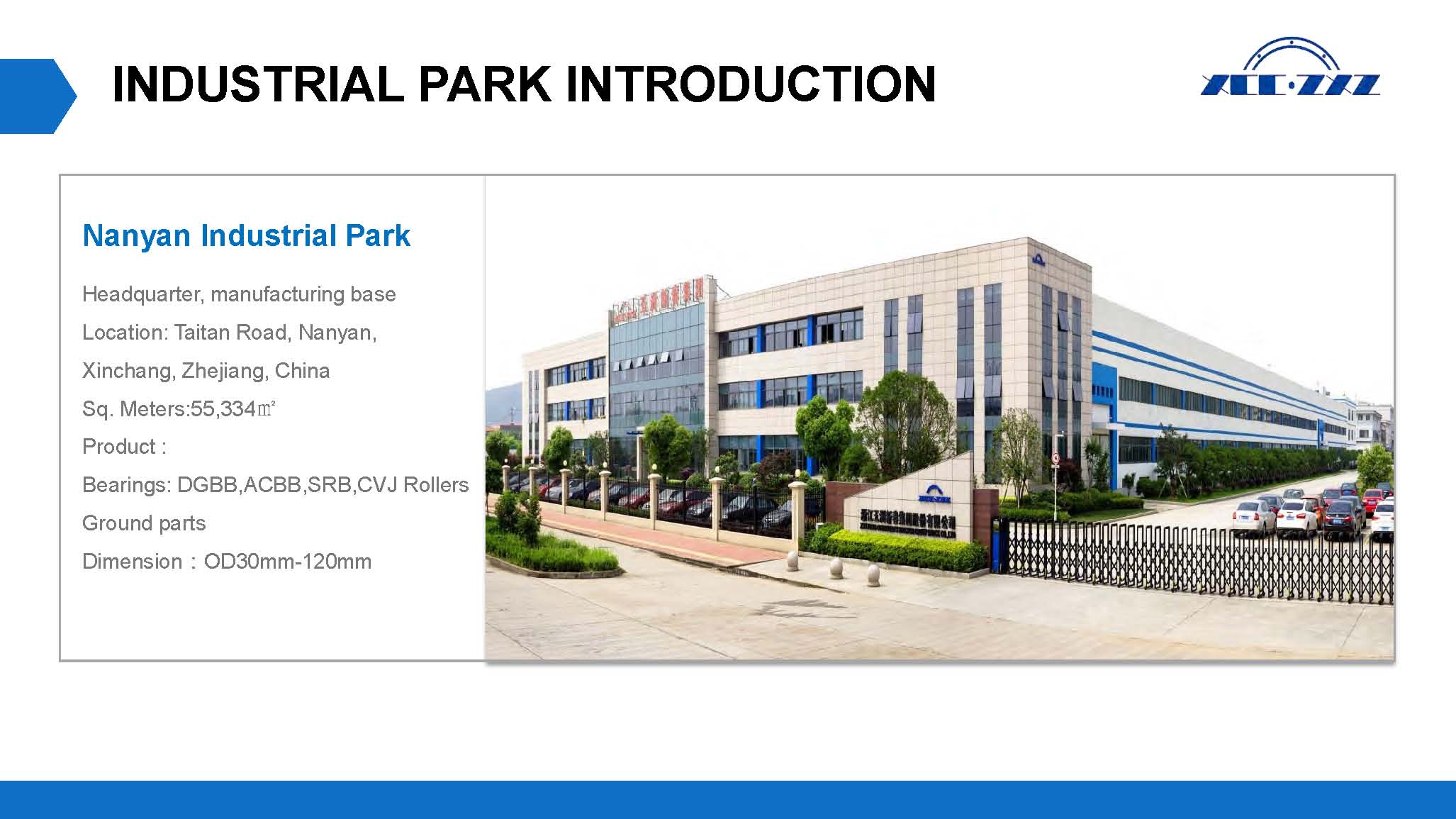

XCC Group is China listed group enterprise (stock code: 603667) with more than 10 subsidiaries, specialized in the fields of bearings, bearing parts and Auto Parts manufacturing.

Regard the R&D and innovation as the fundamental of a company, and provide the product exceeding the customer expectation. Digitized simulation software and static-dynamic simulation analyzation help to achieve the highly CAE; we also adopt nanoscale level of run out.ultra-precision measuring instruments of contour, etc. To meet the need of high precision bearings inspection; digital controlled simulation test equipment of bearing performance can conduct fully simulation tests according to the working condition. Professional engineers keep creating, improving the production technology to improve machinery efficiency and product precision. ZXZ has built the Post-doctoral work station, provincial technology center and Enterprise Institute.

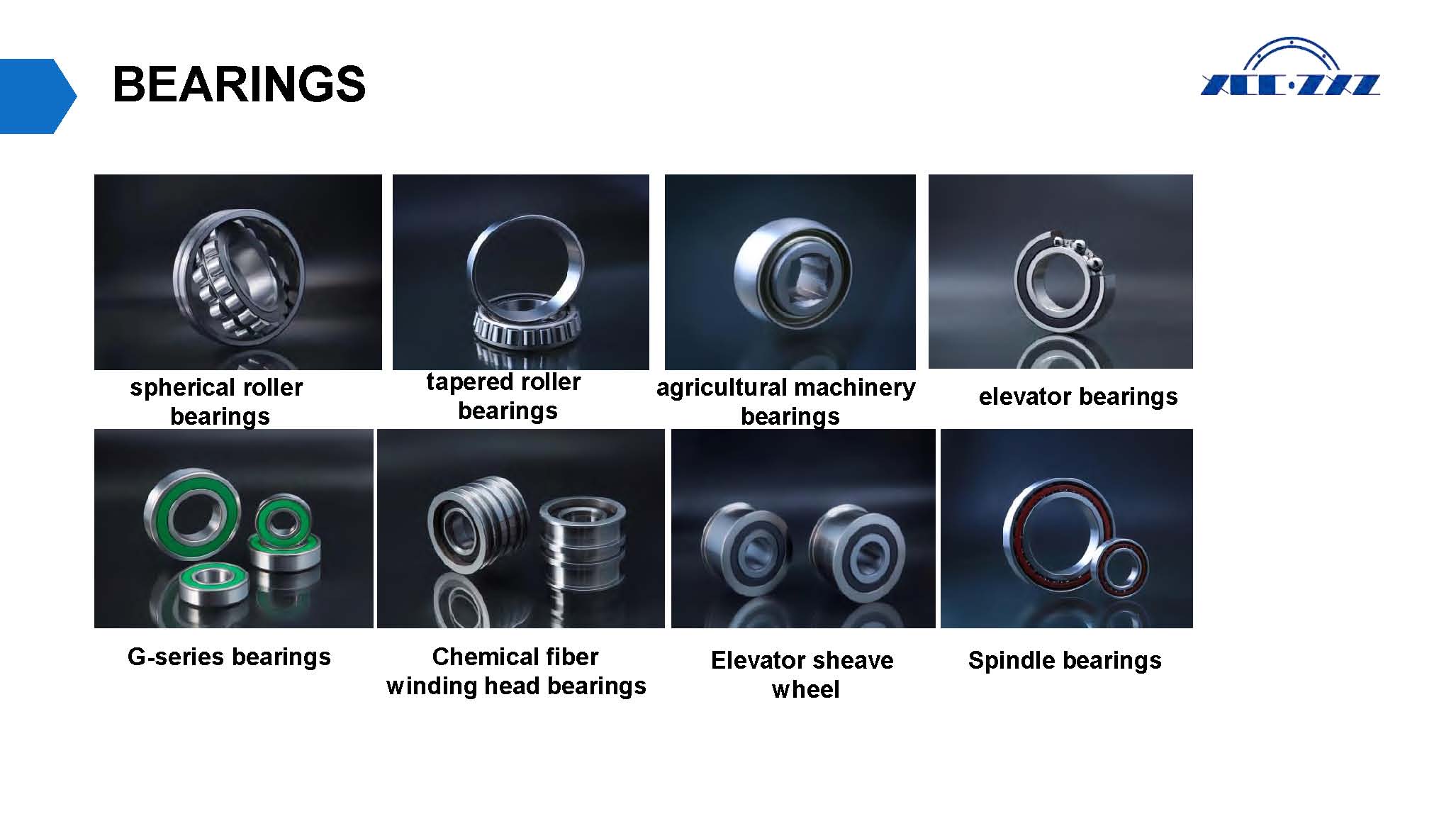

XCC has an integrated bearing production chain what combined with R&D, tubing, forging, turning, heat treating, grinding etc. Including auto Alternator Bearings,tension bearings, air-conditioner clutch bearings, Water Pump Bearings, Precision Machine Tool Bearings, chemical fiber & textile machinery bearings, as well as whole series of standard and non-standard Deep Groove Ball Bearings etc with high precision, high speed, low noise and long life.

ZXZ build up entire bearing production line from steel tube, forging, turning, heat treatment to grinding and assembling after 10 years effort; high quality bearing rings which do heat treatment already provide for top 5 bearing manufacturer worldwide, production capacity reach 200 million sets annually; adopt full automatic CNC grinding and assembly line, benefit from big amount of advanced manufacturing equipment, ZXZ has ability to service for world class level customers.

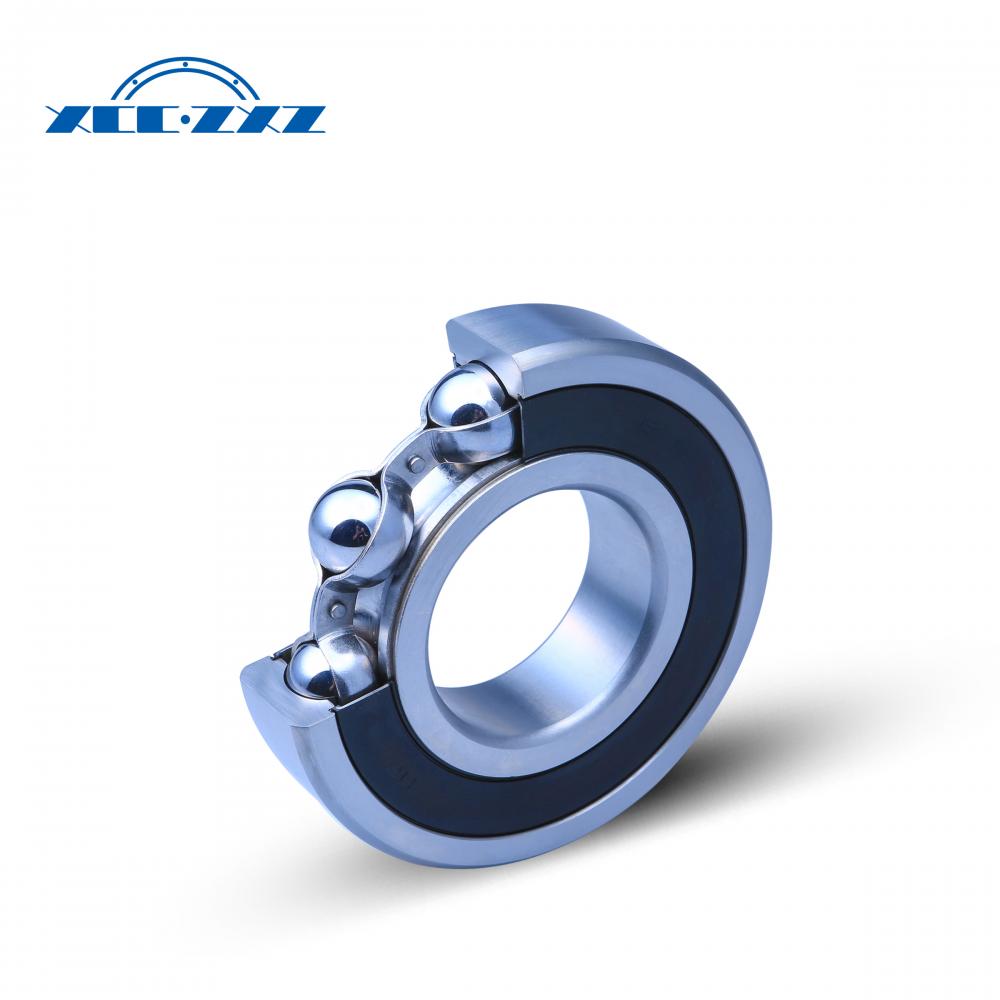

ZXZ ball bearing elevator

Deep groove ball bearings are widely used, the raceway and the steel ball have excellent close fit to realize low friction rolling Sealed deep groove ball bearing is widely used in elevator Which have two designs with dust cover on both sides (2Z) and seal ring on both sides(2RS). Sealed deep groove ball bearings are pre-installed with high quality grease to ensure maintenance free throughout the lift life cycle.

The inner and outer rings of deep groove ball bearings are inseparable and can bear radial load and two-way axial load, so they can make a fixed end. If used as a floating bearing, a ring must be set to a loose fit. The misalignment compensation ability of single row deep groove ball bearing is limited, the misalignment will result in the adverse running state of the rolling body, and the internal stress of the bearing will increase, thus shortening the working life of the bearing.

The allowable inclination angles of single row deep groove ball bearings.

Series

The

angle of inclination

Light

load

Heavy

load

62.622.63.623.64

5'-10'

8'-16'

618.619.160/60

2'-6'

5'-10'

Elevator deep groove ball bearings generally operates under low speed and heavy load, so the fitting accuracy should be appropriately improved, and the internal clearance after installation should be accurately calculated to ensure the operation under a small amount of negative clearance and improve the reliability of bearing.

In a permanent magnet synchronous traction machine, requires low operating noise, can be achieved by using axial preload spring to reduce deep groove ball bearing axial clearance the purpose of reducing noise. According to experience, the preload of the spring can meet this requirement if it reaches 1-2% of the rated dynamic load Cr of the selected bearing.

In addition, the axial preloading spring can also avoid the false brints caused by false brints on the bearing raceway during transportation of the traction machine or in a vibrating environment, where the axial pre-tightening force can reach 3-4% of the rated dynamic load Cr of the selected bearing.

Video

Shaoxing, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier