1 / 5

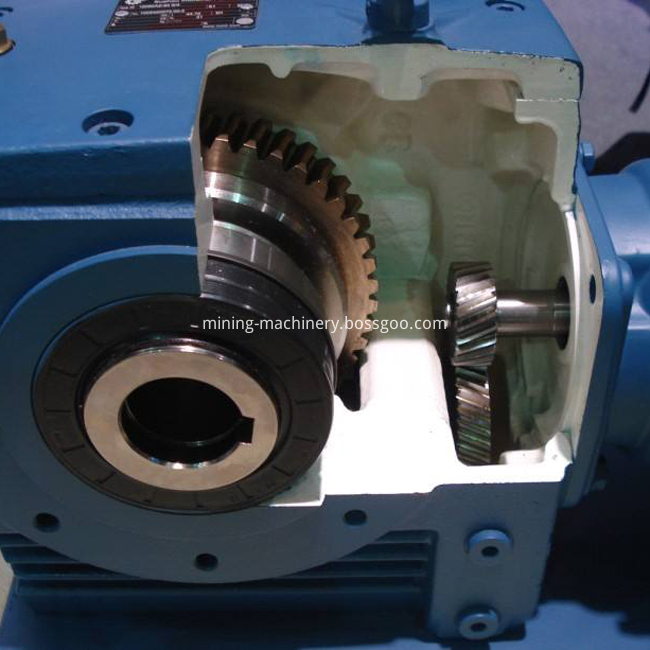

Worm Drive Speed Reducer Deceleration Device

| Model No. : | Standard |

|---|---|

| Brand Name : | DONGDA |

| Power Source : | DC Motor |

Jining, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Product description

Worm Drive Speed Reducer Deceleration Device

Product information

Worm Drive Speed Reducer Deceleration Device, According to the wear problem, the traditional solution is machined repair after repair welding or brush plating, but both has certain disadvantages: repair welding high temperature thermal stress can not completely eliminate, easy cause material damage, lead to bend or break parts and brush plating coating thickness restrictions, easy to peel, and two methods above are with metal repair of metal, can't change "hard to hard" cooperate relationship, under the force combination, still can cause wear again. Speed Reducer Deceleration Device For some large bearing enterprises are unable to solve on site, more dependent on external repair.Modern western countries often use polymer composite repair methods for the above problems, which have super adhesion, excellent compressive strength and other comprehensive properties. Worm Drive Speed Reducer, Application of high polymer material to repair, can neither from removed from machining repair welding thermal stress effect, repair the thickness is not restricted, and the product of metal materials do not have rolled back, can absorb the impact of vibration equipment, avoid wear and tear, and greatly prolong the service life of equipment components, save a lot of downtime for the enterprise, creating huge economic value.

Worm Drive Deceleration Device, And for leakage problem, traditional methods need to be removed and open the reducer, the replacement of sealing gaskets or daub sealant, not only time-consuming, laborious and difficult to ensure the sealing effect, in the run will leak again.Leakage of high polymer material can be on-site management, materials have excellent adhesion, oil resistance, and 350% of the tensile strength, overcome the impact of vibration reducer, well solve the problem of the speed reducer leakage for the enterprise.

Cause analysis of Worm Drive Speed Reducer Deceleration Device

1, reducer, both inside and outside differential pressure: reducer operation process, movement vice friction heat and influenced by environmental temperature, the temperature rise of the gearbox, if there is no breather hole or blockage in a breather hole, is increasing pressure on machine, machine the higher the temperature, pressure difference with the outside world, the greater the oil under the action of pressure difference, the leakage from the gap.

2. The structure design of the reducer is unreasonable

1) check that the hole cover plate is too thin, and after tightening the bolt, it is easy to generate deformation, making the joint surface uneven and leaking oil from the contact gap;

2) during the construction of deceleration mechanism, the casting did not undergo annealing or aging treatment, and the internal stress was not eliminated, so deformation was inevitable, resulting in clearance and leakage.

3) there is no oil return groove on the box body, and the lubricating oil accumulates at the shaft seal, end cover, binding surface, etc. Under the action of pressure difference, it leaks out from the gap;

4) unreasonable design of shaft seal structure.The early reducer used oil groove, felt ring shaft seal structure, when the assembly of the felt compression deformation, and the joint surface gap seal up.If the shaft neck is not in good contact with the sealing parts, the sealing will fail in a short time due to the poor compensation performance of the felt.Although there are oil return hole in the oil groove, it is easy to block up and the oil return function is difficult to play.

3, amount to much: reducer in the process of operation, the oil pool was badly agitation, lubricating oil and splatter everywhere inside the machine, if the amount is overmuch, make a lot of lubricating oil accumulation in the place such as shaft seal, in combination with surface, lead to leakage.

4, improper maintenance technology: in equipment maintenance, due to the combined surface dirt removal is not complete, or sealant improper selection, seal, not timely replacement seal way, etc. Can also cause oil leakage.

Dongda Group has 10 series, more than 70 products. Including mines lifting equipment, transport equipment, communication signal equipment, personal-protective equipment, ventilation equipment, mining cleaning equipment, supporting equipment, drilling machines and accessories, mining pump, electrical equipment, lighting equipment ,rock drilling equipment and other products.

Our factory have 10 series type include more than 40 differently products

Mainly products: coal feeder, mine pneumatic pump, wear resistant steel plate, mine car, production rescuer equipment, pneumatic mine car arrested stopper, air cannon, rolling cage equipment, coal mining prompt transportation, electrical machinery, agriculture machinery etc.

Jining, Shandong, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier