Video

1 / 2

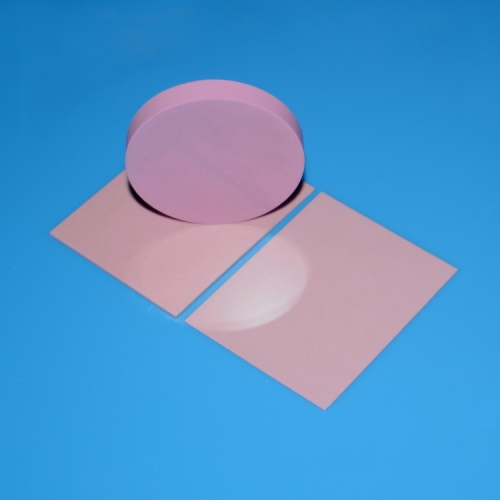

Pink Alumina Polished Ceramic Substrate

| Model No. : | Customized |

|---|---|

| Brand Name : | Jinghui Ceramic |

| place of origin : | China |

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

Pink Alumina Polished Ceramic Substrate

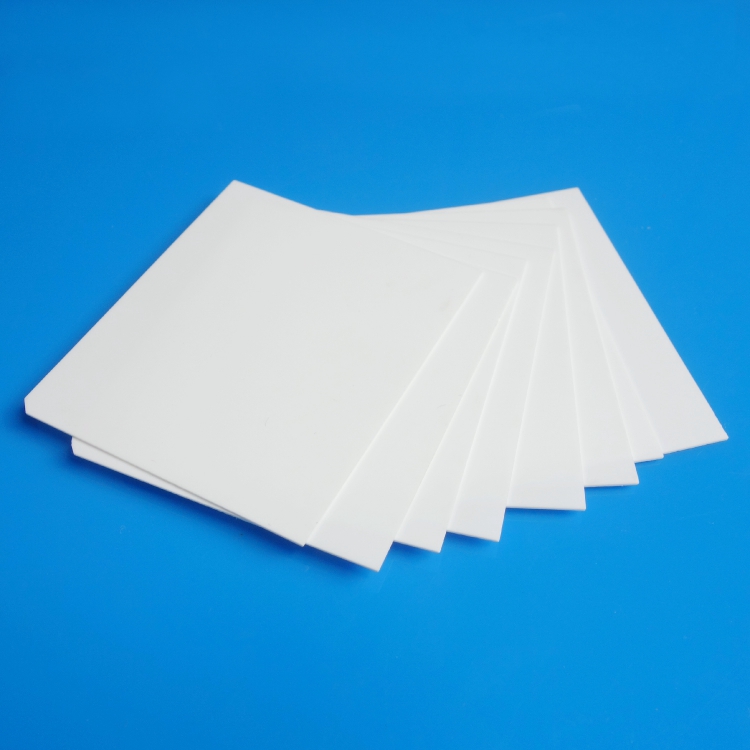

We produce a variety of alumina, zirconium oxide and aluminum nitride ceramic substrates through tape casting or dry pressing processes. For example, for 96% alumina ceramic substrates, our standard thicknesses are 0.25mm, 0.30mm, 0.38mm, 0.50mm, 0.635mm, 0.76mm, 0.8mm, 0.89mm, 1.0mm, 1.5mm, and 2mm. In addition, we can customize the thickness.

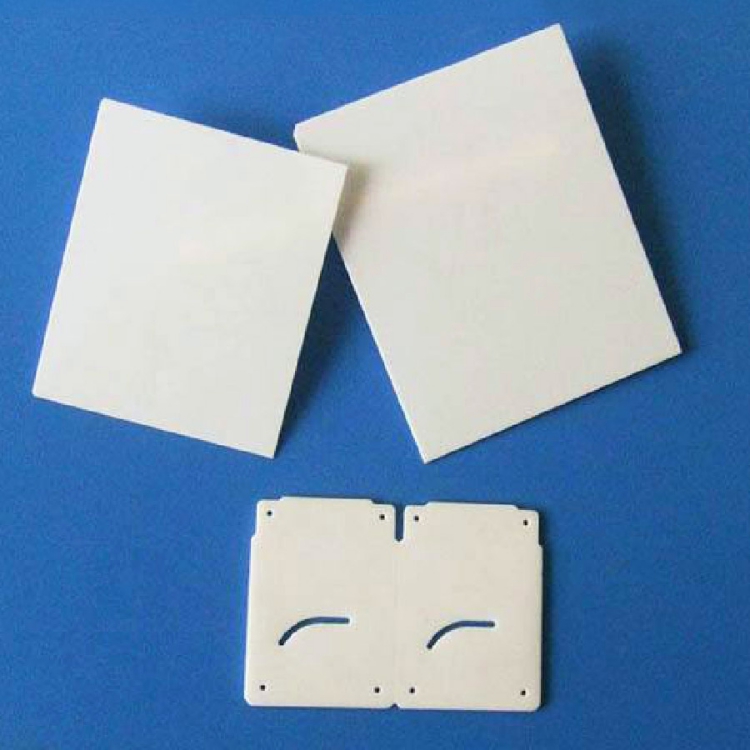

We can achieve various complex shapes, high-precision surface treatment and precise dimensional requirements through fine grinding, polishing, lapping, cutting, CNC machining, etc.

Introduction of Alumina Ceramic Substrate

Alumina ceramic is the most commonly used ceramic substrate material and is favored for its good comprehensive properties. The advantages of alumina ceramic substrates include excellent insulation properties, excellent high temperature resistance, high strength and hardness, outstanding chemical stability and good processability. The main applications of alumina ceramic substrates are as follows:

1. Ceramic Substrate for Chip Resistors

Alumina ceramic substrates have the advantages of small size, light weight, low thermal expansion coefficient, high reliability, high thermal conductivity and high density. They greatly improve the reliability and wiring density of circuits, making them ideal carrier materials for chip resistive components.

2. Hybrid Integrated Circuit Ceramic Substrate

Metallized ceramic substrates serve as deposition sites for dielectric and resistive materials, providing mechanical support for all passive and active chip components of hybrid integrated circuits.

3. Ceramic Substrate for Power Devices

For the packaging of power electronic devices, the substrate not only needs to provide basic wiring (interconnection) functions, but also needs to provide high thermal conductivity, insulation, heat resistance, voltage resistance and thermal matching capabilities. Metalized ceramic substrates such as alumina DBC ceramic substrates and DPC ceramic substrates have superior properties in terms of thermal conductivity, insulation, voltage resistance, and heat resistance, and have become the preferred material for power device packaging.

Related Product Display

Video

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier