1 / 5

Welding machines, wire cage machines, Wire cage, Cage welding machine, wire cage machine, Round wire

Get Latest Price

Send Inquiry

| Model No. : | hgz1500 |

|---|---|

| Brand Name : | Odea |

| Type : | Steel Processing Machinery |

More

Weifang odea Machinery Co., LTD

You might also like

Product description

Detailed

1. Working Principle:

The cage welding machine consist of 4 parts of driven systems, inclusive Master plate of Rotation, Plate

of push reinforcing steel , expansion diameter part, and welding machine. The 4 parts are drived by

independent electrical motor. The Full variable frequency control ensures that the span of the latitude steel

and the angle of the spigot won`t not change along with the welding speed. Adjustment the ratio of motor

speed can change the span of latitude steel, and angel of spigot. This machine can weld different diameter

cages via adjustment of location and position of the master plate and welder.cage welding machine is a

special-purpose welder used to produce the high-strength concrete pipe pile reinforcement cages.

The welder is widely applied to reinforcement cage welding by self-stressing and prestressing pretensioning

method and post-tensioning method.

1. Large diameter of weldable main reinforcement, long frame, small torsion and good integral performance;

2. Small weld strength loss;

3. Adjustable cage pitch and quick forming;

4. High-speed and stable operation and high efficiency;

5. Variable frequency control and high stability and reliability;

6. Rational structure and easy and convenient operation and maintenance.

2. Features:

1.Automatic PLC control, Man-machine interface, Touch screen.

2.Variable Frequency Speed control and inverter;

3.Pneumatic clamping system, Gear wheel chain on the main plate;

4.Transformer and electrode water cooling system.

It makes up of four systems:The Main plate; Pushing Plate; Diameter changing; and Cooper welder,they

are working, driven by the separate motor.

The Variable Frequency Ratio speed control system will promise the spiral pitch.

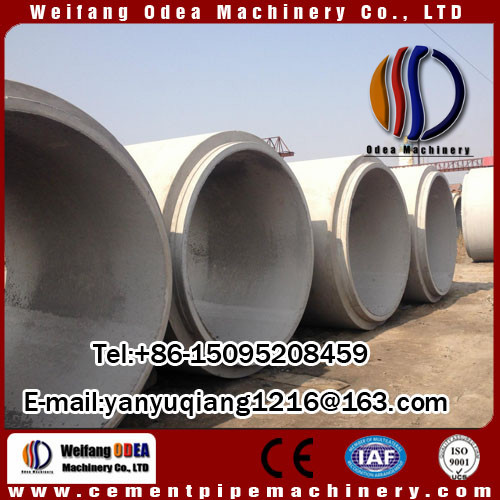

3.Product Picture:

|

Specification |

Parameter |

|

Validity Dia |

Socket: 800-1800mm Flat: 800-2000mm |

|

Max length of welding |

4000mm |

|

Dia.of steel wire |

Latitude:3.5-6mm Longitude:4-6mm |

|

Quantity of longitude wire |

12 |

|

Span between latitude wire |

20-150mm |

|

Angle of spigot |

10-25degree |

|

Rotation speed of main plate |

0-10RPM |

|

Motor power |

0.55+1.1+2.2KW |

|

Transformer power |

|

Supplier's popular products

Send your inquiry to this supplier

Send Inquiry