1 / 5

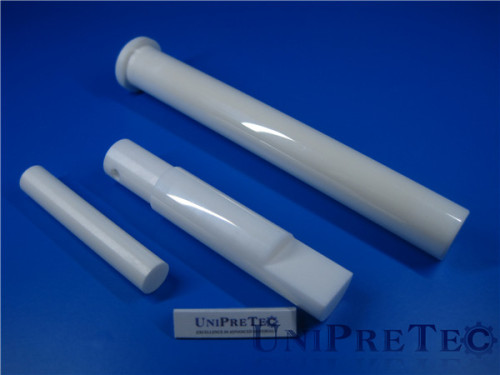

Wear Resistance Yttria Stabilized Zirconia Y-TZP Ceramic Plunger Shafts

| Model No. : | UPT-ZC003 |

|---|---|

| Brand Name : | UNIPRETEC |

Product description

Wear Resistance Yttria Stabilized Zirconia Y-TZP Ceramic Plunger Shafts

Ceramic plunger shaft, is widely used in petroleum, chemical, food, textile, medical and other industries, such products with high wear resistance, corrosion resistance, impact resistance, the operating life is 5-10 times of metal plunger shafts.

1.Material: Zirconia Ceramic, ZrO2 Ceramic, Zirconium Oxide

2.Product Feture of Ceramic Plunger Shafts

*Product Feture

*High temperature capability up to 2400oC

*High density

*High strength and fracture toughness

*High hardness and wear resistance(far higher than Stainless steel,Brass,Plastics)

*Low thermal conductivity (20% that of Alumina)

*Good chemical resistance

*Ionic conductivity

Application of Zirconia Ceramics

1.Precision ball valve (balls and seats)

2.Pump seals, valves and impellors

3.High density grinding media

4.Oxygen sensors

5.Threadguides

5.Fuel cell membranes

6.Cutting blades

7.Radio frequency heating susceptors

8.Medical prostheses

9.Metrology components

About UniPreTec

UniPreTec provides high-performance ceramic products in Alumina, Zirconia, Zirconia Toughened Alumina, Silicon Carbide, Silicon Nitride and further special materials. Along with these materials, we offer several machining from which to choose such as cutting, drilling, sawing, turning, grinding, polishing etc.. Furthermore, our technologies and equipments allow us to provide various and flexible forming processes, like dry pressing, isostatic pressing, extrusion, injection moulding and slip casting.

Send your inquiry to this supplier