1 / 2

Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump

Get Latest Price

Send Inquiry

| Model No. : | 2/1.5B-MH |

|---|---|

| Brand Name : | GS |

Shijiazhuang Gravel Slurry Pump Industry Co., Ltd.

You might also like

Product description

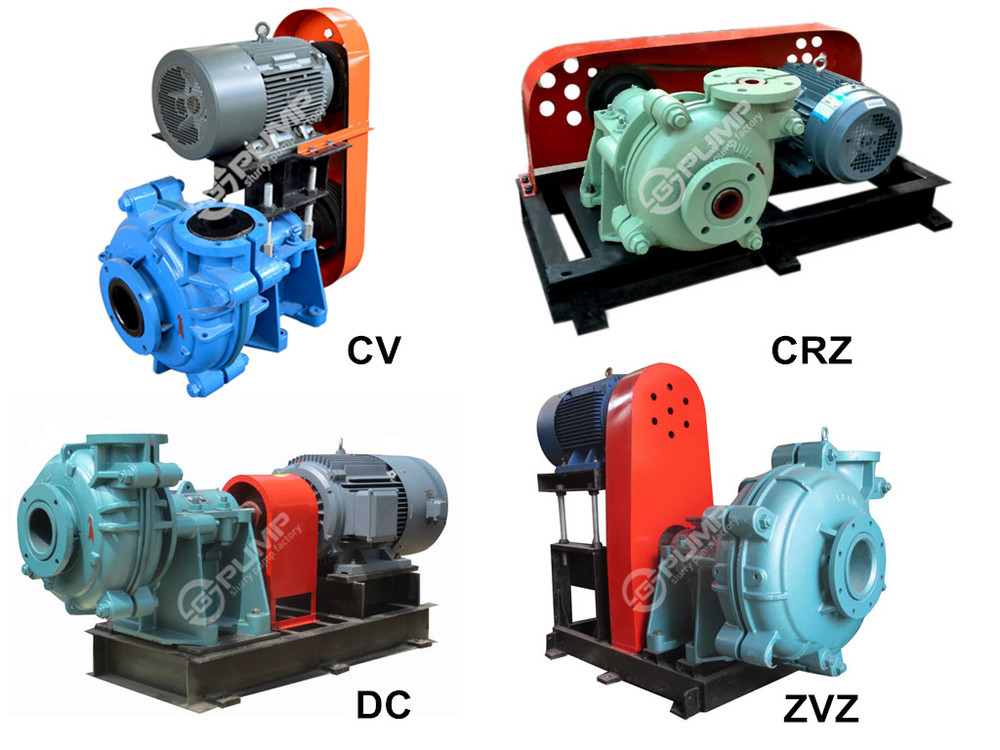

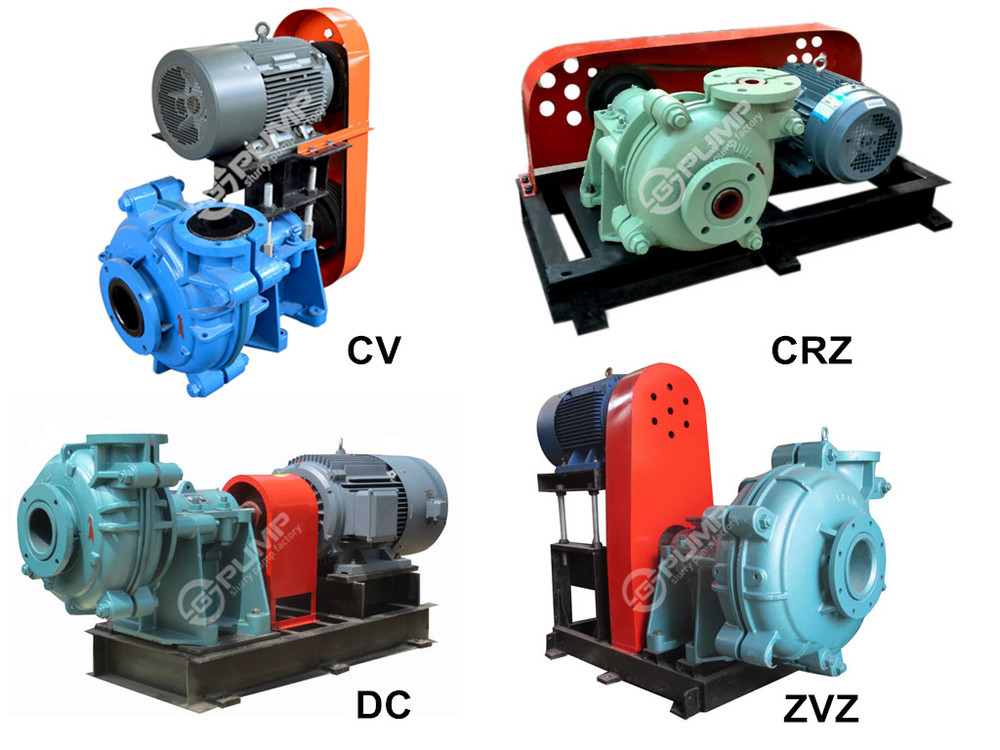

Company Information: Shijiazhuang Gravel Slurry Pump Industry Co.,ltd locates in Shijiazhuang, Hebei Province, China, it is an integrative production, research, design and sales company, specialized in manufacturing slurry pump products. The company acting as one of the national heavy machinery industry unit, now has been developed into a professional manufacturer of slurry pump, mud pump, slush pump, foam pump, sand-slurry pump. Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump

Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump Product Advanstage: Wear – resistant rubber as liners prolongs the service life by 2-4 times

Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump Product Advanstage: Wear – resistant rubber as liners prolongs the service life by 2-4 times

Internal rubber liners with small specific gravity can effectively improve the impeller speed. Maximum flow rate than other slurry pump can improve the efficiency of the whole 10-20%, overall efficiency increased more than 30%.Small specific gravity wet parts, convenient maintenance, low noise; reduce the number of repair personnel and the operational maintenance cost Smooth wet parts make operation more stable The True Ultra Heavy Duty Slurry Pump Warman Ultra Heavy Duty Horizontal Slurry Pumps Designed for the continuous pumping of highly abrasive, high density slurries with minimal maintenance requirements, the Warman horizontal centrifugal pumps will maintain high efficiencies over the wear life of its components.

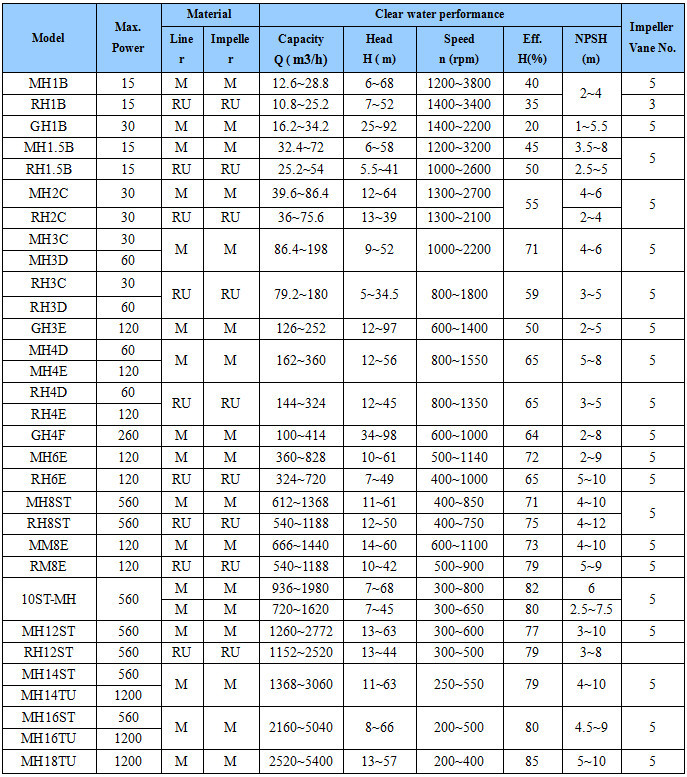

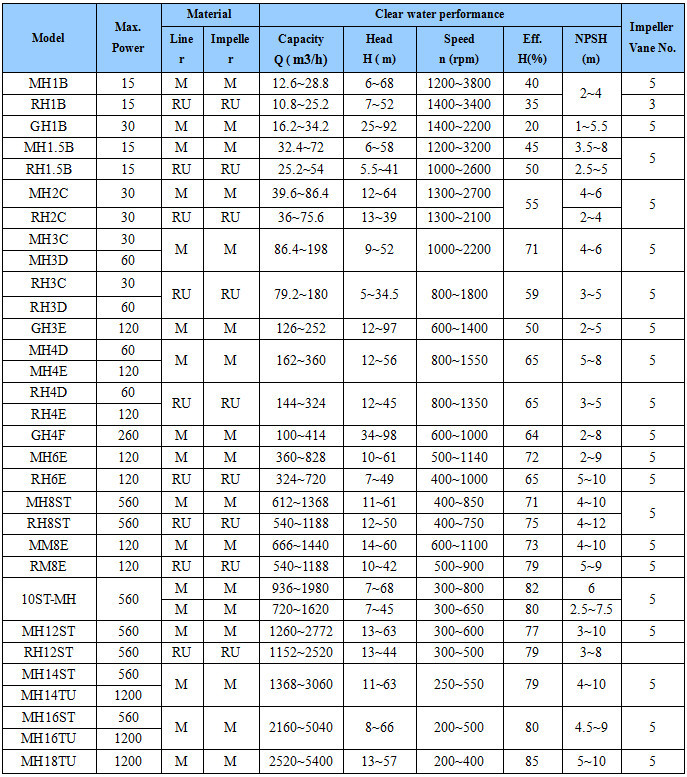

Warman rubber and metal lined pumps feature casings which are radially split into two halves. Minimum casing bolts reduce maintenance and minimise downtime.Mouldedimpellers and loose liners are available in various elastomers. Loose metalliners and impellers are also available in abrasive resistant alloys and various corrosion resistant metals.Both metal or rubber liners and impellers, or a combination of both, areinterchangeable within the same pump to facilitate use in various applications.Outline dimensions are common to both metal and rubber pumps allowing interchangeability without pipeline or civils rework being necessary.A removable cartridge type grease lubricated bearing assembly can be replaced with the pump base in-situ, facilitating easy maintenance. Extra heavy duty and oil lubricated bearing assemblies are available on request.Pumps are available with an optional centrifugal shaft seal which eliminates the need for gland sealing water. This reduces costs, eliminates product dilution and is suitable where suction conditions permit. For intermittent duties, the unique Warman Dyna Seal eliminates leakages whilst the pump is stationary. Configurations of metal and rubber lined pumps of the same frame size use thesame base, bearing assembly, stuffing box and shaft sleeve, reducing stockholding to a minimum.Polyurethane, stainless steel, ceramic and various hard wearing alloys are available on request Parameter selection: M H 1 B M:Metal slurry pump H:Heavy duty slurry pump 1:Suction diameter(inch) B:Base type

Parameter selection: M H 1 B M:Metal slurry pump H:Heavy duty slurry pump 1:Suction diameter(inch) B:Base type

Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump Drive Type:

Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump Drive Type:  Certification:

Certification:  Typical Applications

Typical Applications

Chemical Process

Heavy Minerals

Paper and Pulp

Mill Discharge

Sugar Beet

Slag Granulation

Bottom Boiler and Fly Ash

Cyclone Feed

Power Utilities Packing&Shipping:

Packing&Shipping:  FAQ 1.How about your slurry pump price? We are sure our price is reasonable , not the lowest. good price based on good quality. 2.What is the slurry pump material ? Slurry pump is made of high chrome, very abrasive-resistant metal.the shaft is made of 45steel and the bearings are famous brand in China, or we can use SKF if clients need. 3. What kind of liquid can your pump transfer? water+ sand, solid, sludge, gravel, stones and so on. 4.Is it easy for customers to change the parts by themselves ? yes, the structure is simple ,customers can change it very easily. 5.How about your slurry pump warranty? 1 year warranty for pump, 3 months for wet parts 6.how to do if the pump or parts have quality problem within your warranty? Show us pictures, we will send you a news one at once without any hesitation. 7.Can you install the motor or diesel engine with the pump for us ? yes, we can ,we are experienced in this . 8.Our work condition don't have water to seal the pump, how to do ? We can make the pump with expeller seal , you need not inject the water to seal, just grease to seal. 9.we don't know which model we need ,can you help us ? yes, please let us know the pump capacity ,head , then we can help you to calculate . 10.How long can you reply us if we send an inquiry ? within 20 minutes within our working hours, if out of our working hours, we will reply you at once when I am in office. Thanks for your reading. any questions or request, Don't hesitate to contact us.We are glad to help you,We believe we can supply good pump and good service. Contact us:

FAQ 1.How about your slurry pump price? We are sure our price is reasonable , not the lowest. good price based on good quality. 2.What is the slurry pump material ? Slurry pump is made of high chrome, very abrasive-resistant metal.the shaft is made of 45steel and the bearings are famous brand in China, or we can use SKF if clients need. 3. What kind of liquid can your pump transfer? water+ sand, solid, sludge, gravel, stones and so on. 4.Is it easy for customers to change the parts by themselves ? yes, the structure is simple ,customers can change it very easily. 5.How about your slurry pump warranty? 1 year warranty for pump, 3 months for wet parts 6.how to do if the pump or parts have quality problem within your warranty? Show us pictures, we will send you a news one at once without any hesitation. 7.Can you install the motor or diesel engine with the pump for us ? yes, we can ,we are experienced in this . 8.Our work condition don't have water to seal the pump, how to do ? We can make the pump with expeller seal , you need not inject the water to seal, just grease to seal. 9.we don't know which model we need ,can you help us ? yes, please let us know the pump capacity ,head , then we can help you to calculate . 10.How long can you reply us if we send an inquiry ? within 20 minutes within our working hours, if out of our working hours, we will reply you at once when I am in office. Thanks for your reading. any questions or request, Don't hesitate to contact us.We are glad to help you,We believe we can supply good pump and good service. Contact us:

Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump Product Advanstage: Wear – resistant rubber as liners prolongs the service life by 2-4 times

Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump Product Advanstage: Wear – resistant rubber as liners prolongs the service life by 2-4 timesInternal rubber liners with small specific gravity can effectively improve the impeller speed. Maximum flow rate than other slurry pump can improve the efficiency of the whole 10-20%, overall efficiency increased more than 30%.Small specific gravity wet parts, convenient maintenance, low noise; reduce the number of repair personnel and the operational maintenance cost Smooth wet parts make operation more stable The True Ultra Heavy Duty Slurry Pump Warman Ultra Heavy Duty Horizontal Slurry Pumps Designed for the continuous pumping of highly abrasive, high density slurries with minimal maintenance requirements, the Warman horizontal centrifugal pumps will maintain high efficiencies over the wear life of its components.

Warman rubber and metal lined pumps feature casings which are radially split into two halves. Minimum casing bolts reduce maintenance and minimise downtime.Mouldedimpellers and loose liners are available in various elastomers. Loose metalliners and impellers are also available in abrasive resistant alloys and various corrosion resistant metals.Both metal or rubber liners and impellers, or a combination of both, areinterchangeable within the same pump to facilitate use in various applications.Outline dimensions are common to both metal and rubber pumps allowing interchangeability without pipeline or civils rework being necessary.A removable cartridge type grease lubricated bearing assembly can be replaced with the pump base in-situ, facilitating easy maintenance. Extra heavy duty and oil lubricated bearing assemblies are available on request.Pumps are available with an optional centrifugal shaft seal which eliminates the need for gland sealing water. This reduces costs, eliminates product dilution and is suitable where suction conditions permit. For intermittent duties, the unique Warman Dyna Seal eliminates leakages whilst the pump is stationary. Configurations of metal and rubber lined pumps of the same frame size use thesame base, bearing assembly, stuffing box and shaft sleeve, reducing stockholding to a minimum.Polyurethane, stainless steel, ceramic and various hard wearing alloys are available on request

Parameter selection: M H 1 B M:Metal slurry pump H:Heavy duty slurry pump 1:Suction diameter(inch) B:Base type

Parameter selection: M H 1 B M:Metal slurry pump H:Heavy duty slurry pump 1:Suction diameter(inch) B:Base type

Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump Drive Type:

Wear & Corrosion Ceramic Liner Mining Iron sillica Ore Slurry Pump Drive Type:  Certification:

Certification:  Typical Applications

Typical ApplicationsChemical Process

Heavy Minerals

Paper and Pulp

Mill Discharge

Sugar Beet

Slag Granulation

Bottom Boiler and Fly Ash

Cyclone Feed

Power Utilities

Packing&Shipping:

Packing&Shipping:  FAQ 1.How about your slurry pump price? We are sure our price is reasonable , not the lowest. good price based on good quality. 2.What is the slurry pump material ? Slurry pump is made of high chrome, very abrasive-resistant metal.the shaft is made of 45steel and the bearings are famous brand in China, or we can use SKF if clients need. 3. What kind of liquid can your pump transfer? water+ sand, solid, sludge, gravel, stones and so on. 4.Is it easy for customers to change the parts by themselves ? yes, the structure is simple ,customers can change it very easily. 5.How about your slurry pump warranty? 1 year warranty for pump, 3 months for wet parts 6.how to do if the pump or parts have quality problem within your warranty? Show us pictures, we will send you a news one at once without any hesitation. 7.Can you install the motor or diesel engine with the pump for us ? yes, we can ,we are experienced in this . 8.Our work condition don't have water to seal the pump, how to do ? We can make the pump with expeller seal , you need not inject the water to seal, just grease to seal. 9.we don't know which model we need ,can you help us ? yes, please let us know the pump capacity ,head , then we can help you to calculate . 10.How long can you reply us if we send an inquiry ? within 20 minutes within our working hours, if out of our working hours, we will reply you at once when I am in office. Thanks for your reading. any questions or request, Don't hesitate to contact us.We are glad to help you,We believe we can supply good pump and good service. Contact us:

FAQ 1.How about your slurry pump price? We are sure our price is reasonable , not the lowest. good price based on good quality. 2.What is the slurry pump material ? Slurry pump is made of high chrome, very abrasive-resistant metal.the shaft is made of 45steel and the bearings are famous brand in China, or we can use SKF if clients need. 3. What kind of liquid can your pump transfer? water+ sand, solid, sludge, gravel, stones and so on. 4.Is it easy for customers to change the parts by themselves ? yes, the structure is simple ,customers can change it very easily. 5.How about your slurry pump warranty? 1 year warranty for pump, 3 months for wet parts 6.how to do if the pump or parts have quality problem within your warranty? Show us pictures, we will send you a news one at once without any hesitation. 7.Can you install the motor or diesel engine with the pump for us ? yes, we can ,we are experienced in this . 8.Our work condition don't have water to seal the pump, how to do ? We can make the pump with expeller seal , you need not inject the water to seal, just grease to seal. 9.we don't know which model we need ,can you help us ? yes, please let us know the pump capacity ,head , then we can help you to calculate . 10.How long can you reply us if we send an inquiry ? within 20 minutes within our working hours, if out of our working hours, we will reply you at once when I am in office. Thanks for your reading. any questions or request, Don't hesitate to contact us.We are glad to help you,We believe we can supply good pump and good service. Contact us:

Send your inquiry to this supplier

Send Inquiry