1 / 1

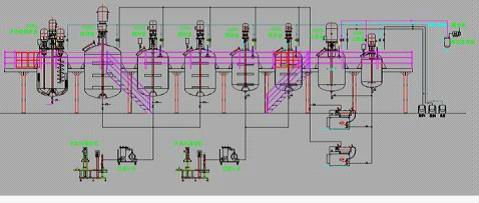

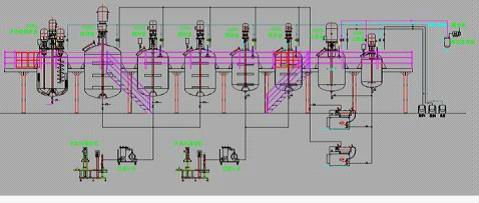

Water Based Paint Machine

Get Latest Price

Send Inquiry

| Model No. : | YRCE |

|---|---|

| Brand Name : | Ranen |

Shanghai Yuanrun New Energy Equipment Technology Co.,Ltd.

You might also like

Product description

Water Based Paint Machine Introduction Complete production line with an annual output of 40000tons.Ranen provides customized made design to satisfy different production process and throughput. The whole process of the line is dispersing-milling-mixing-deironing filter-discharge tank 1 .The production of solvent based coatings can reach to1000 tons to 50 thousand tons annual , the complete production line is particularly suitable for large-scale production. 2 Configuration of equipment could be designed according to the customer's process and output, such as product category, fineness, yield, etc.; 3 .Super fine grinding machine is used for dispersing and grinding. The efficiency is high, the fineness is good, the cleaning is convenient, and the residue is little. 4 The whole set of equipment can automatically complete feeding, dispersion, grinding, mixing, filtering, filling and the whole process. the production process is very concontration, less human factors, easy to produce and manage. 5. Solvent based paint complete equipment has many automation control links such as: automatic control vacuum feed pump, feeding, you can use volumetric metering and weighing metering, automation PLC man-machine interface can control the production process, production recipe is designed with database, door alarm device mal operation and self-locking function. The cooperation of the software and hardware makes the production stability, greatly reducing the error caused by human factors and helping to improve the quality of products Features 1. Sealed reaction, safe operation & environmental friendly 2. Custom-made design and qualified fabrication 3. Configured with basket mill or horizontal sand mill: efficient grinding, good fineness, easy to clean, no residuals and color contamination 4. Separate operation process from vacuum feeding, dispersion, grinding, cooling, tinting, filtration to filling 5. High automation, less human operation, easy for management 6. Automatic design is available from auto-feeding, online testing to auto-metering & dosing Technical Specifications

![]()

![]() Ranentech is a technology-oriented and fast-developing company which integrates R&D, design, manufacture, sales and customer service. We have a modern factory in Shanghai, covering an area of 4000 sqm and bring together a highly experienced technicians and service-oriented backup team to serve our customers with extensive resources and high-quality equipment.

Ranentech is a technology-oriented and fast-developing company which integrates R&D, design, manufacture, sales and customer service. We have a modern factory in Shanghai, covering an area of 4000 sqm and bring together a highly experienced technicians and service-oriented backup team to serve our customers with extensive resources and high-quality equipment.

Our main products include high-speed disperser, wet grinding mill, planetary mixer, deironing filter, reactor & tank, and complete production line, with wide application such as li-ion battery industry, paint and ink industry, pesticide & fertilizer industry, food and pharmacy industry etc.

With rich industry experience, strong R&D and efficient manufacturing, we always provide our customers high-quality equipment and service. Factory Display

Our Culture

Our Culture  Certification

Certification  Contact Us

Contact Us

Main parts | Introduction |

Main reactor | material: CS, SS, glass steel for option |

heat transfer: jacket, coiler pipe | |

mixing agitator: impeller, anchor, or turbine type | |

sealing system: mechanical seal, packing seal | |

Condenser and reflux devicer | vertical condenser |

horizontal condenser | |

water separator | |

Dilution tank | tank material: CS, SS, glass steel for option |

Heating system | steam heating |

hot water heating | |

hot oil heating | |

Electrical control system | manual/semi-automatic/full automatic control |

Our main products include high-speed disperser, wet grinding mill, planetary mixer, deironing filter, reactor & tank, and complete production line, with wide application such as li-ion battery industry, paint and ink industry, pesticide & fertilizer industry, food and pharmacy industry etc.

With rich industry experience, strong R&D and efficient manufacturing, we always provide our customers high-quality equipment and service. Factory Display

Our Culture

Our Culture  Certification

Certification  Contact Us

Contact Us

Send your inquiry to this supplier

Send Inquiry