1 / 2

Vertical Shaft Impact Crusher (PCX-600)

Get Latest Price

Send Inquiry

| Model No. : | PCX-600 |

|---|

Zhengzhou Dingsheng Engineering Technology Co., Ltd.

You might also like

Product description

Product Description

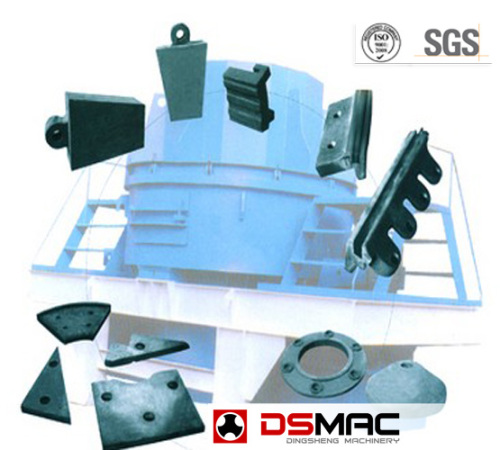

Vertical Shaft Impact Crusher (PCX-600)

PCX-600 Sand Maker

Max feed (mm): 35

Power (kw): 22~55

Impeller Speed (r/min): 2000~3000

Production Capacity(t/h): 12~30(-0.8mm30%)(-0.8mm60~90%)

Dimension(mm): 2500*1600*2260

Vertical Shaft Impact Crusher (PCX-600) Introduction

The DSMAC PCX series VSI is unique due to its crushing process. Whereas most other types of crusher use metallic parts to crush rock, the VSI uses the rock fed into the machine to crush itself. This autogenously crushing process produces the best-shaped aggregate on the market today.

Vertical Shaft Impact Crusher (PCX-600) is Ideal for

1. Cover some special secondary applications but especially tertiary and quaternary applications;

2. Construction, industrial minerals, metallic minerals and waste and recycling applications;

3. Quality aggregates, sand, material for heap leaching, pre-grinding and finished industrial minerals products.

PCX series VSI crusher Application

1. Aggregates and sand. The quarry industry has been the traditional home of the DSMAC VSI. VSIs are particularly successful in producing road-base, top dressing chip, concrete and asphalt aggregates, and manufactured sand;

2. Industrial minerals. With features such as controlled product grading, preferential crushing, low production costs and the ability to produce finely graded products, the addition of VSI can optimize the performance of most industrial mineral processing installations;

3. Mining. High capacity and ability to produce finely graded products such as mill feed, sinter feed or material for heap leach operations, is an ideal machine to replace high cost, inefficient crushing and milling equipment;

4. Waste recycling. Recycled materials not only take the form of mineral aggregates for the construction industry, but also glass, slags and other waste products that can be processed and profitably sold. The DSMAC VSI provides the perfect means of treating these materials.

To Get Process Benefits of Vertical Shaft Impact Crusher (PCX-600)

1. Lower wear costs per ton. In some cases average wear part lives have increased by 50%. This means less maintenance time and higher crusher availability;

2. Highest flakiness/shape index of aggregates produced;

3. Crushing ratio easy adjustable as per rotation speed modification (the machine can be quickly tuned to face process needs);

4. Easy Maintenance;

5. High capacity (up to 500 tph). A denser particle population in the chamber will give more effective reduction and improved shape;

6. Possibility to re-crush unsold small materials (2-6 mm; 4-8 mm, ^) and single fraction round materials (16-32mm, ^).

PCX-600 Sand Maker

Max feed (mm): 35

Power (kw): 22~55

Impeller Speed (r/min): 2000~3000

Production Capacity(t/h): 12~30(-0.8mm30%)(-0.8mm60~90%)

Dimension(mm): 2500*1600*2260

Vertical Shaft Impact Crusher (PCX-600) Introduction

The DSMAC PCX series VSI is unique due to its crushing process. Whereas most other types of crusher use metallic parts to crush rock, the VSI uses the rock fed into the machine to crush itself. This autogenously crushing process produces the best-shaped aggregate on the market today.

Vertical Shaft Impact Crusher (PCX-600) is Ideal for

1. Cover some special secondary applications but especially tertiary and quaternary applications;

2. Construction, industrial minerals, metallic minerals and waste and recycling applications;

3. Quality aggregates, sand, material for heap leaching, pre-grinding and finished industrial minerals products.

PCX series VSI crusher Application

1. Aggregates and sand. The quarry industry has been the traditional home of the DSMAC VSI. VSIs are particularly successful in producing road-base, top dressing chip, concrete and asphalt aggregates, and manufactured sand;

2. Industrial minerals. With features such as controlled product grading, preferential crushing, low production costs and the ability to produce finely graded products, the addition of VSI can optimize the performance of most industrial mineral processing installations;

3. Mining. High capacity and ability to produce finely graded products such as mill feed, sinter feed or material for heap leach operations, is an ideal machine to replace high cost, inefficient crushing and milling equipment;

4. Waste recycling. Recycled materials not only take the form of mineral aggregates for the construction industry, but also glass, slags and other waste products that can be processed and profitably sold. The DSMAC VSI provides the perfect means of treating these materials.

To Get Process Benefits of Vertical Shaft Impact Crusher (PCX-600)

1. Lower wear costs per ton. In some cases average wear part lives have increased by 50%. This means less maintenance time and higher crusher availability;

2. Highest flakiness/shape index of aggregates produced;

3. Crushing ratio easy adjustable as per rotation speed modification (the machine can be quickly tuned to face process needs);

4. Easy Maintenance;

5. High capacity (up to 500 tph). A denser particle population in the chamber will give more effective reduction and improved shape;

6. Possibility to re-crush unsold small materials (2-6 mm; 4-8 mm, ^) and single fraction round materials (16-32mm, ^).

| Type and spec. |

Max. feeding granularity (mm) |

Impeller rotate-speed (r/m) |

Electric motor power (kw) |

Production capacity (t/h) |

Figure size (mm) |

| PCX-600 | 35 | 2000-3000 | 22-5 | 12-30 | 2500×1600×2260 |

| PCX-750 | 45 | 1500-2500 | 45-90 | 25-55 | 2780×1800×2700 |

| PCX900 | 50 | 1200-2000 | 90-180 | 55-100 | 3900×2160×2770 |

| PCX1050 | 55 | 1000-1700 | 150-264 | 100-160 | 4660×2450×3660 |

| PCX-1250 | 60 | 850-1450 | 264-440 | 160-300 | 5600×2950×4000 |

Send your inquiry to this supplier

Send Inquiry