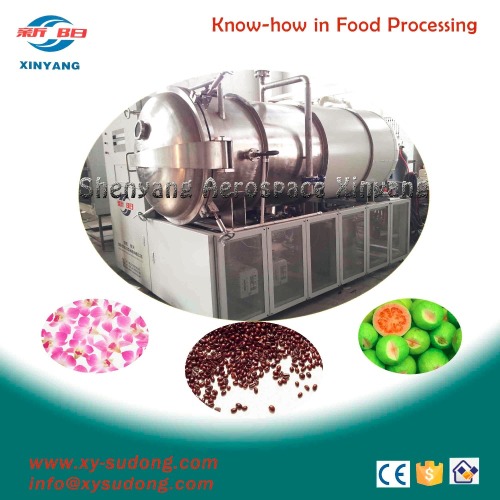

Product Description Decription of freeze dryer Vacuum freeze drying technology is the most advanced technology for food dehydration processing at present. Compared with the common drying method, the freeze-dried food produced with this technology features long period of quality assurance, good re-hydration nature, good-looking color, good flavor, taste, shape and high content of nutritious components. The dried food basically remains unchanged in its volume and shape, it looks like sponge and has no shrinking. This kind drying technology can be widely used in process of vegetables, fruits, condiments, aquatic products, biological products, medicine, beverage and etc. 1, Taste. fresh Freeze-dried foods, like frozen, retain virtually all their fresh-food taste and nutritional content. Freeze-drying removes the water, not the flavor. 2,Look fresh. Freeze-dried foods maintain their original shape and texture, unlike dehydrated foods, which shrink and shrivel due to high-temperature processing. Freeze-drying removes water under low temperatures which keeps intact the moisture channels and food fibers. Just add water, and in minutes every fresh food detail returns. 3,Weigh less than fresh. Freeze-dried foods have 98% of their water removed. This reduces the food's weight by about 90%. 4, Stay fresh. Freeze-dried foods can be stored at room temperature, without deterioration or spoilage. This is because freeze-drying and packaging remove both water and oxygen - the two primary causes of food deterioration. With over 1000 freeze dryers installed worldwide and more than 30 years experience ,Xinyang's freeze drying equipment is used in a wide range of industries across the world. 1. Efficiency of Heating plates The material of heating plates are aviation aluminum with anodized on the surface, over 100% heat release to the product by radiation way, keep good heating uniformity everywhere. 2. Automatic control system Advanced intelligent control system keeps whole system stable and reliable running for a long term, furthermore, Simple operation method can be much easier to master. 3. "Product curve and data" record & save function Adopt advanced design idea, all in the process of running data recorded and stored in a computer, for the data reference of next time, at the same time, it is eay to find out the actual situation of equipment operation by these data. The main technical data: Dimension(L*W*H): 3500x2300x2300mm Dimension of heating plates 300*330*8mm Free distance between heating plates 82mm Number of heating plates 8pcs Heating type Double-sided radiation Heating medium, max. temperature 130C Dimension of trays 300*330*35mm Number of trays 14 Nominal H2O sublimation capacity 10kg/h Nominal working pressure 20~133Pa Time for pumping down 12min Refrigeration capacity needed (-35℃evaporating) 10kw Install power 35kw Voltage: 380~460v Weight: 2.5Ton Advantages 1. Efficiency of Heating plates The material of heating plates are aviation aluminum with anodized on the surface, over 100% heat release to the product by radiation way, keep good heating uniformity everywhere. 2. Alternate Vapor trap Double vapor trap located under the heating plates inside drying chamber, Just trap 1 condensates water vapor until it can't catch vapor any more, then trap 2 starts condensation function, and trap 1 will begin to be defrost ice for another condensation cycle. 3. Continous De-icing When the trap 2 begins to catch water vapor, the trap 1 begins to be defrost ice on the tube bundle during product drying, after de-icing, the empty and smooth tubes for another condensation cycle. 4. Automatic control system Advanced intelligent control system keeps whole system stable and reliable running for a long term, furthermore, Simple operation method can be much easier to master. Model& Specification

Specification Model | LG0.2 | LG1.0 | LG1.5 | LG5 | LG10 | LG20 |

Heating Areas(m2) | 0.2 | 0.8 | 1.5 | 5.3 | 10 | 20 |

Numbers of Vapor trap | Single | Single | Single | Single | Single | Single | Double |

Trapping Capacity | >2kg/batch | >8kg/batch | >20kg/batch | >65kg/batch | >130kg/batch | >250kg/batch | >44kg/hr |

Heating Medium | Electric | Electric | Electric | Water&electric | Water&electric | Water&electric | Water&Steam |

Heating Mode | Double side radiation |

Temperature range of Heating plates | Normal Temp.~+120℃ | <95℃ | <95℃ | <95℃ | Normal Temp.~+130℃ |

Vacuum Pressure (Pa) | 20~133 |

Need Refrigeration Capacity (t0=-40℃,tk=-35℃) (Kw) | With Refrigeration System | 18 | 35 | 44 |

Consumption of Steam (kg/h) | None | None | None | None | 50 | None | 75 |

Electric Power Supply (Kw) | 3.2 | 8.5 | 15 | 35 | 26 | 65 | 38 |

Tray Numbers | 2 | 4 | 4 | 14 | 26 | 52 | 54 |

Loading Raw Material | 3 | 8 | 20 | >70 | >130 | >260 | >270 |

Product Pictures

Warranty 1.We guarantee that the commodity hereof is made of the best materials and new brand with top workmanship, and in accordance with quality specification stipulated in product Contract and

Appendix. 2. Guarantee period shall be within 12 months from the date of acceptance. During this period, if

there are quality problems, we will provide solution by verbal or written communication. If the

problem is unsolved, our engineers will repair for you on site as soon as possible. The

maintenance is free when there are non-operation errors; otherwise it is for the buyer’s account. Our Services Training plan: We will provide training for those who operate and maintain the freeze-drying

machines. Trained by supplier of the equipment in the process of installation and debugging,

people can operate and solve the basic mechnical problems independently. In addition, the persons

who work in general engineering such as refrigeration, boiler, and transformer substation shall be

undertaken by skilled workers.

Company Information

Warranty 1.We guarantee that the commodity hereof is made of the best materials and new brand with top workmanship, and in accordance with quality specification stipulated in product Contract and

Warranty 1.We guarantee that the commodity hereof is made of the best materials and new brand with top workmanship, and in accordance with quality specification stipulated in product Contract and