1 / 1

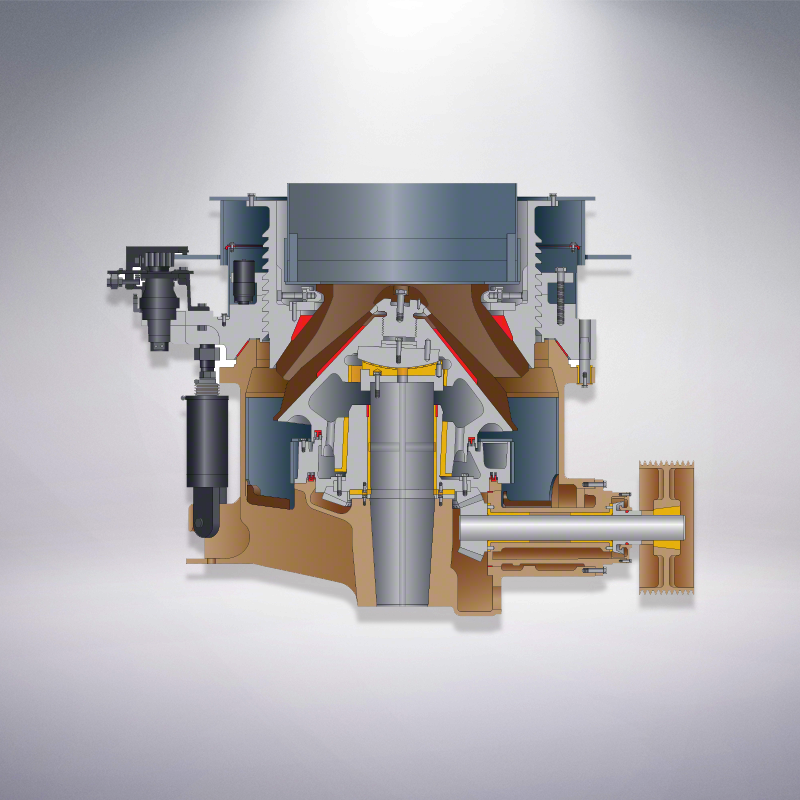

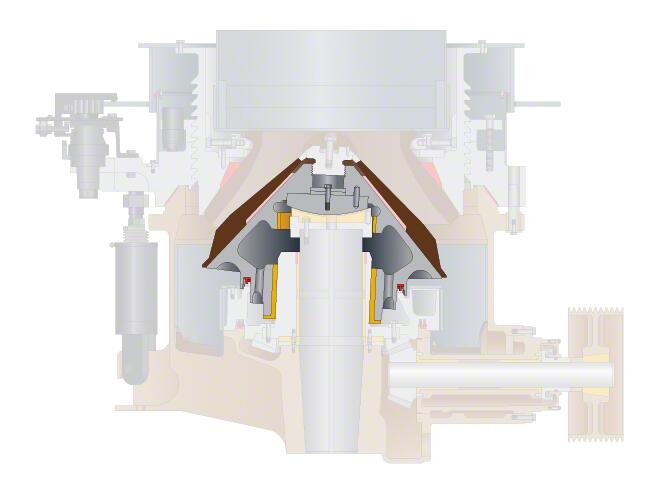

Upper Head wear bush

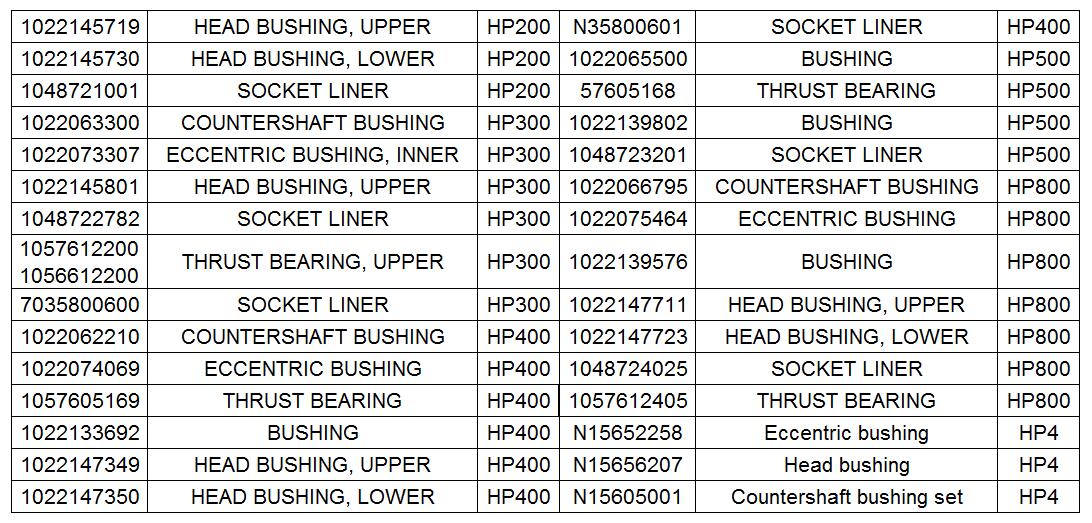

| Model No. : | HP200 HP300 HP400 HP500 HP800 |

|---|---|

| Certification: : | ISO9001:2008 |

Shenyang, Liaoning, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Video

Product description

In the working process of cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone swings under the force of the eccentric sleeve. The section of the moving cone near the static cone becomes the crushing chamber, and the material is crushed by the multiple extrusion and impact of the moving cone and the static cone. When the moving cone leaves this section, the material that has broken to the required size falls under its own gravity and is discharged from the bottom of the cone. In order to reduce the wear between the eccentric bushing and the shaft, bushing is usually set between them. However, the existing bushing is only a cylindrical bushing. Because of the lack of lubricant between bushing and eccentric bushing and shaft, it is easy to wear and damage bushing. Its frequent replacement greatly affects the production efficiency.ronze.

Specifications

High level surface finish

100% testing before its delivery.

Produced as drawings and requirement strictly.

Shenyang YYD casting Co., Ltd. is located at Shenyang Industrial City, in the North eastern of China. Our company is a professional manufacturer of brass and bronze products in China.We specialize bushing in Tin-copper bronze, Aluminum-copper bronze, Zinc-copper bronze, Manganese-copper bronze.

Our company has constantly imported advanced equipment, and persisted in high quality. Therefore, we can provide better services to related manufacturing industry, and pursue ceaseless improvement. We adhere to the operation concept of "quality, reputation, efficiency and return" and persistently stick to our idea of continual operation.

Our company has passed the evaluation of ISO9001:2008 quality certification. Thanks to our excellent production equipment, strong technology supports, fine inspection measures, and our center lab inspection (including material texture test and analysis, test for intensity and hardness), our products sell well in more than 20 provinces and cities in domestic market, and are exported to more than 10 countries and regions, such as Russia, America, Germany, Malaysia, Australia, South Africa and Italy.

Please feel free to contact us for further information.

FAQ

1.Q: What products do you offer?

A: Shenyang YYD Casting provides parts are

tailored with your requirements. It ranges mainly from METSO crusher parts,

especially HP series, totally replacement parts, we also welcome OEM offer from

you.

2. Q: What materials can you make?

A: Tin-copper bronze, Aluminum-copper bronze, Zinc-copper

bronze, Manganese-copper bronze and other material according to customer

provided.

3. Q: How about the capacity? What is the max dimension?

A: The capacity is 30 tons per month. The max

dimension we have casted is 5meter.

4. Q: What information should we provide to you to

confirm our order of parts?

A: For standard part, you only need to provide the

part number than we will define the part. But others, you should provide the

technical drawings of your parts.

5. Q: What's the after-sales service if your

product has quality problem?

A: First of all, you should provide us photos of

the problem part and machine then our engineers will collect the necessary

information to find the root cause. If it's indeed a quality problem of the

product itself, we must afford compensation to you and also figure out

solutions to avoid the same problem. However if it's caused by client's

misconduct, we also provide the technical suggestions for our clients to solve

problem better.

6. Q: Can we visit your factory?

A: Yes, of course, welcome to our factory in

workday and our sales team will show you everything you want to know.

Shenyang, Liaoning, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Video

Send your inquiry to this supplier