1 / 5

Torch-on spun-bond polyester reinforced SBS waterproof membrane

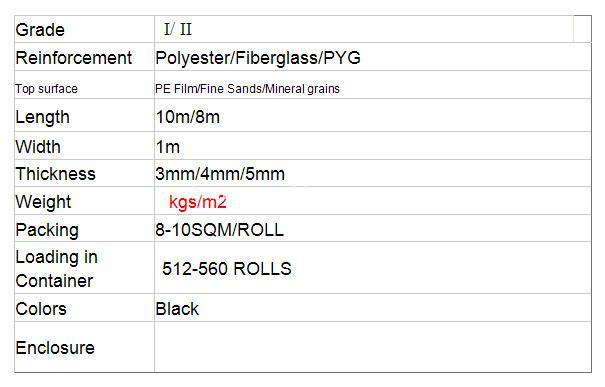

| Model No. : | CLS-8000 |

|---|---|

| Brand Name : | Kunteng |

Weifang, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

Torch-on spun-bond polyester reinforced SBS waterproof membrane

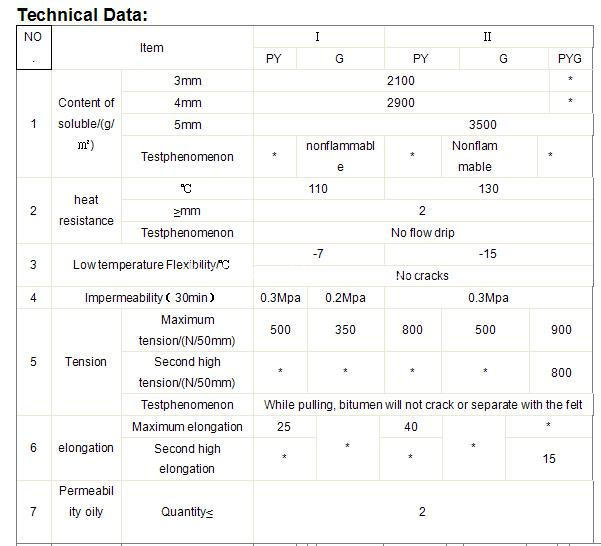

Bitumen membrane type roof waterproofing is made by soaking the base in bitumen,or thermoplastic elastomer(such as styrene butadiene-SBS), or thermoplastics (such as atactic polypropylene-APP,APAO,APAL) modified bitumen, then covering double faces with elastomer(SBS) or thermoplastics( APP, APAO,APAL) modified bitumen, and last finishing the upward face with fine sands, mineral slates(or grains) or polythene membrane ect, while downward face with fine sands or polythene membrane.

Bitumen is still the best-known waterproofing material. However, it has poor aging characteristics, becomes brittle in cold weather, is fluid in hot weather, and has little resistance to fatigue. Elastomeric compounds such as SBS (styrene-butadiene-styrene) substantially improve these properties. SBS rubber is flexible and has the memory to return to its original form.SBS (Styrene-Butadiene-Styrene) modifies the asphalt by forming a polymer network within the bitumen. SBS gives the bitumen rubber-like characteristics and improved resistance to aging and weathering.

Application

Make sure the roof deck smooth, and dry (moisture<9%), then apply the surface oroof deck homogeneously with a kind bitumen paint, till dry to start application.

There are two methods in application:

One way is by heating and melting method. Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted (not flowing), then install the membrane filly bonded to the roof deck with overlaps of 5-250px.b. The other way is by cold adhesive method. Pour the cold adhesive homogeneously on the roof deck, then roll the membrane to install it to be fully slicked to roof deck. By heating and melting method and by cold adhesive can be used in alternation in application as requested.

after application, a full serious inspection is required to sure no air bubble, no falling away, etc. to guarantee the waterproof life.

Storage

Storage and transportation, the different types and specifications of the products should be stacked separately and

should not be mixed. The storage temperature should not be higher than 50 ° C, stand up storage height of not

more than two layers;

Storage and transport of different types and specifications of products should be stacked separately and should not

be mixed. The storage temperature should not be higher than 50 ° C, stand up storage height of not more than

two layers;

normal storage conditions of transport, storage from the period from the date of production for one year.

Weifang, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier