1 / 4

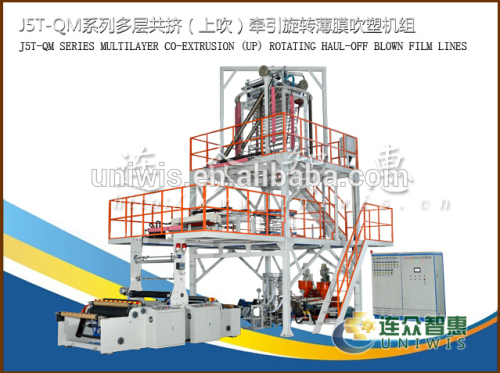

three layer coextrusion ibc haul-off blown film machine

Get Latest Price

Send Inquiry

| Model No. : | J5T-QM1300(~2300) |

|---|---|

| Brand Name : | Uniwis |

FUJIAN UNIWIS INDUSTRIAL CO., LTD.

You might also like

Product description

Parameters

2.Lubricating System: Taiwan Famous Automatic Oiling System; 3.Pneumatic System: Japan SMC. Machine details   Factory Scenery Factory Scenery  Packing & Delivery Packing & Delivery   Exhibition Exhibition  Installation Services Installation ServicesInstallation services are available for all new machine purchases. We will provide professional technician to your company to support for installating, debugging and operating of the machine.The technician will indicate you how to use the machine as well. After Sales Services We offer one year guarantee period and offer comprehensive maintenace options to prevent equipment issues before they become problems. You can send e-mail, make phone call to contact us with your problem.We will do our best to solove the problem. Factory visit welcome.You can see our website for more product information, please don't hesitate to call. please visit our websit : uniwis.en.alibaba.com Send your inquiry to this supplier Send Inquiry

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||