1 / 5

Three / Five Layers Stretch Film Unit

| Model No. : | CL-75/120/75C |

|---|---|

| Brand Name : | CHANGLONG MACHINE |

| Type : | Profile Extruder |

Shenzhen, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

- The Belt And Road

- Video

Product description

High Speed Three / Five Layers Stretch Film Line

This machine uses LLDPE, PE, CPE, PP as main material and adopts several kinds of resigns to produce the single or double-side self-sticky stretch wrapping film,cling film,emossing film, the film has good tensile strength,anti-pricking ablilty and impact strength. Its good shrinking memory function and self-sticky can make goods integrity to prevent goods from loosening and collapsing during transportation and being polluted by dust.The transparency and tensile strength of this product can make the packaging economical and practical.

Main Technical Parameter:

Model: CL-75/120/75C

Width of Die Head: 2500mm

Width of Film: 2000mm

Thickness of Film: 0.01-0.05mm

Structure of Film Layers: A/B/C or A/C/B/C/A

Liner Speed of Machinery: 300m/min

Max Extrusion Capacity: 625kg/h

Max Rewind Diameter: 460mm

Screw Diameter: 75/120/75mm

L/D Ratio of Screw: 30:1

Motor Power of Main Machine: 37/110/37kw

Total Power: 120-300kw

Overall Dimensions(L*W*H): 12.5*8*5.1m

Total Weight: 32T

Features:

1.The daily output can reach up to 15 tons.

2.Double layers structure, saving a good deal of floor spaces.

3.Screw with Italian design, air heating barrel, 150CC melt metering pump sensor technology to ensure a good heating and cooling, greatly improving product uniformity.

4.High speed 1000mm big diameter cooling roller ,use special double deck chi roll spiral design to ensure excellent cooling effect of stereotypes.

5.Reeling system using middle station mode ,duplex design ,dual-line knife cut film.

6. Constant tension control airshaft center reeling system , Instantaneous cut film.

7.300m/min reeling linear speed ,compare to traditional more that 46%.

8.Automatic change roller ,unwinding ,unloading system ,safe and efficient.

9.The line adopts PLC and touch screen system ,simple and easy to run.

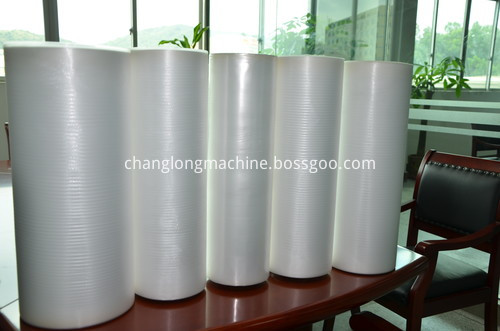

Application

The film can be widely used in packing goods.

Certificate

After-Sales Service

Our professional engineering team is constitutive of excellent technical staff. We can provide perfect after-sales service in time, give a good technical training to ensure the product in best state perennially.

We will respond to customer`s service requests and complaint in the shortest possible time, give a clear reply and solution to deal with in time. At the same time, we sum up customer`s complaint and proposal in order to inherit our advantages, correct our inadequate. We will commit to improve our services quality, so that our customers will be most satisfied.

We offer warranty on product quality and lifelong maintenance services.

Shenzhen, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

- The Belt And Road

- Video

Send your inquiry to this supplier