1 / 5

suspended ceiling track 51 32 mm track 64 32 mm track 92 32 mm track 76 32 mm track 150 32 U roll forming machine

| Model No. : | ZT-009 |

|---|---|

| Brand Name : | Zhongtuo |

| Type : | Cold Bending Equal Channel |

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

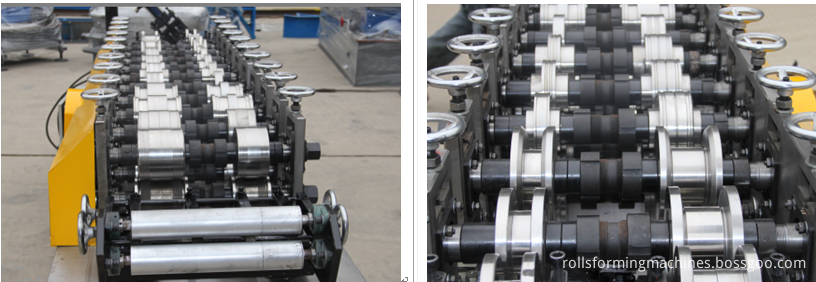

C U ceiling Channel Roll Forming Machine

This ceiling Channel Roll Forming Machine is normal ceiling and drywall channel forming line.There different design solution of this machine. This ceiling Channel Roll Forming Machine is with the : uncoiler, feeding and beveling and roll forming and cutting . The first designing solution is by one mold of changing the gap on the shaft with one cutting system. This designing is with the advantage of save the space, and save the machine cost. The second designing of the solution is by two molds on one shaft and with two sets of molds, one C mold and one U mold. This design can save the time of changing the mold. The third designing mold is one machine table with two separate C machine and U machine, so that the C profile machine and the U profile machine can run at the same time together, also each of the both can run separately. This C U machine design can save much workshop space, can have much high capacity.

Please refer to below machine design picture:

Here are the machine specifications of the one kind of the combined pictures below:

1.Processing flow diagram of machine

Manual decoiler→ → Feeding material into machine →Roll forming machine →Punching→ Measure length →Hydraulic cutting →Finished Products

2. Technical parameters

The suspended ceiling machine is formed by below factors:

manual decoiler / guiding platform / main machine of roll forming / cutting device / electric motor / hydraulic station / Delta PLC control system / run out table.

Material

the Raw material is Galvanized Processing material GI galvanized steel PPGI

the thickness of the raw material is: Thickness 0.4 -0.8mm Material hardness 550-350MPA

Formed width 28/60mm 51/32 mm 64/32mm 76/32 92/32 150/32

yhe suspended ceiling machine Forming speed 25m/min, this speed is a normal speed, the high speed is 60 meters/min,with the servo power to speed up the capacity.

The Manual decoiler specifications is as below:

Inner Diameter:450-550mm

Expand by manual

Outer Diameter: max 1500mm

Max Coil width:300mm

Capacity: 1.5T

Main Forming machine Dimension 4500х1000х1400 L x W x H

Weight of main part: 3 tons

forming steps 10rollers

Shaft diameter 40mm

Design type Memorial arch

roller material GCr12MoV steel

shaft material 45# steel

Transport By gear

Power of main machine 5.5kw

Type of cutting Hydraulic

Cutting tolerance ±1mm

Cutter Gcr12

Cutter quantity 1 set

Working pressure 20MPA

Hydraulic system

Hydraulic oil 46#

Hydraulic power 3kw

Cutting length As required No distorting or wasting. High level safety factor.

Control Device control By PLC

PLC language English and Chinese (or as required)

Brand Generally Delta, or as your requirement Function

Automatic length and quantity measurement

Main body color As you need

Voltage 380v/50hz/3ph(or as required)

Terms of payment

1.Terms of payment: 30%T/T ,Balance to be paid before shipping after inspection.

2.Deliver time: 25 days.

Warranty and Training

1. Warranty: Support the technology all the life. And the machine broken because

of quality, we can change the broken part for free within one year.

2. Training: If you come to our factory,we can teach you for free.

If you need technician go foreign, the buyer need pay the cost for

visa, hotel, ticket, food and others, and buyer need pay the

technician USD50/day for salary.

There need one technician. Training time will be one week.

The photos of the whole 60 27 27 28 machine line picture:

Zhongtuo cold roll forming machine factory is a professional manufacturer in this ceiling and drywall forming machine line.

The engineers can design different kinds of the machine according to your requirements. If you need any of this machine, please feel free let me know, we will make and design the best machine for you!

Below is tips on how to visit our factory:

1 How to get to our factory Zhongtuo cold bending roll forming machine factory?

Our factory is in Cangzhou city, which is near Beijing,China, about one hour by train.

If it is your first time visit China, we would like to pick up you from the airport and send you to the hotel. Also we can recommend you the suitable hotel in our city and book for you.So please do not worry about the transportation and the hotel.

Please refer to below map

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier