Video

1 / 6

Super Strong Permanent ferrite magnet

$0.02

≥10000 Piece/Pieces

$0.01

≥100000 Piece/Pieces

Options:

- D9*10.5MM

- D9*15MM

- D12*18MM

- D12*20MM

- D13.5*21MM

- D14*25MM

- D16*25MM

- D18*30MM

- D19*30MM

Send Inquiry

| Model No. : | D16*25mm |

|---|---|

| Brand Name : | YB |

| place of origin : | China |

More

1yrs

Zhuzhou, Hunan, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

HU NAN YUBANG MAGNETIC MATERIAL CO.,LTD

You might also like

Product description

Sintered ferrite magnet and bonded ferrite magnet are two types of permanent magnets made of ferrite material. However, there are some differences between them, which are as follows:

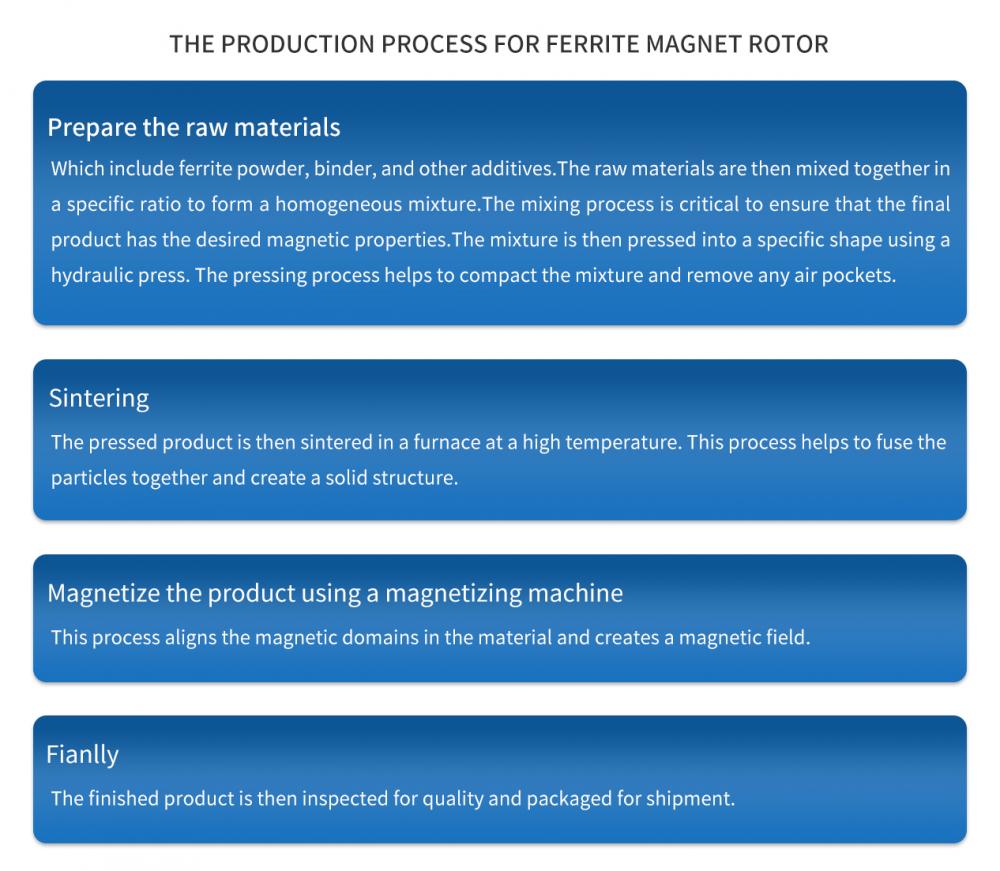

1. Manufacturing process: Sintered ferrite magnets are made by compressing and sintering fine ferrite powder at high temperatures, while bonded ferrite magnets are made by mixing ferrite powder with a binder and then pressing the mixture into a mold.

2. Magnetic properties: Sintered ferrite magnets have higher magnetic properties than bonded ferrite magnets. They have a higher magnetic energy product, coercivity, and remanence.

3. Physical properties: Sintered ferrite magnets are more brittle and prone to cracking than bonded ferrite magnets. Bonded ferrite magnets are more flexible and can be easily molded into different shapes.

4. Cost: Sintered ferrite magnets are more expensive than bonded ferrite magnets due to their higher magnetic properties and more complex manufacturing process.

1. Manufacturing process: Sintered ferrite magnets are made by compressing and sintering fine ferrite powder at high temperatures, while bonded ferrite magnets are made by mixing ferrite powder with a binder and then pressing the mixture into a mold.

2. Magnetic properties: Sintered ferrite magnets have higher magnetic properties than bonded ferrite magnets. They have a higher magnetic energy product, coercivity, and remanence.

3. Physical properties: Sintered ferrite magnets are more brittle and prone to cracking than bonded ferrite magnets. Bonded ferrite magnets are more flexible and can be easily molded into different shapes.

4. Cost: Sintered ferrite magnets are more expensive than bonded ferrite magnets due to their higher magnetic properties and more complex manufacturing process.

Video

1yrs

Zhuzhou, Hunan, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier

Send Inquiry