1 / 6

Super quality promotional aluminum iron alloys produce process

Get Latest Price

Send Inquiry

| Model No. : | worm gear |

|---|---|

| Brand Name : | BRM |

Shanghai United Metal Materials Co., Ltd.

You might also like

Product description

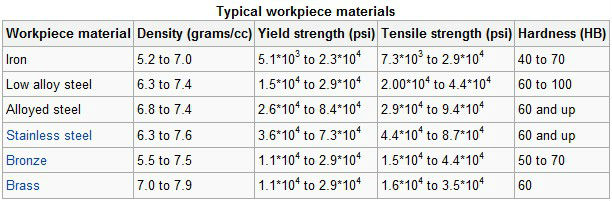

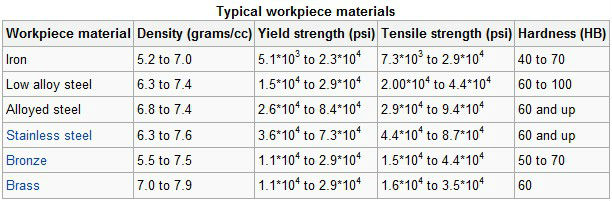

Super quality promotional aluminum iron alloys produce process Feature of aluminum iron alloys produce process: Surface Treatment:electro polishing(low gloss/ medium gloss), electro plating, sandblasting, blackening,pickling, dull finish etc. Property: High strength and intensity,high hardness, and good elongation. Advantages:reasonable price and qualified quality, professional and first-class service. Certifications: ISO9001/14000, GB/T28001 and TS-16949.ROHS ♣ The more complicated your product is, the more cost saving it will be. ♣ We are professional and experienced in exporting. The more complicated your product is, the more cost saving it will be. ♣ Please do not hesitate to contact us with the following infomation if you have intention of purchasing,thanks 1.Drawings with dimensions and tolerances,material and surface treatment. 2.Monthly or annual purchasing quantity 3.package and other requirements Introduction of aluminum iron alloys produce process: Powder compaction is the process of compacting metal powder in a die through the application of high pressures. Typically the tools are held in the vertical orientation with the punch tool forming the bottom of the cavity. The powder is then compacted into a shape and then ejected from the die cavity. In a number of these applications the parts may require very little additional work for their intended use; making for very cost efficient manufacturing. Production rates of 15 to 30 parts per minutes are common. Geometrical Possibilities: Typical workpiece sizes range from 0.25 in (6.35 mm) to 0.75 in (19.05 mm) thick and 0.5 in (12.70 mm) to 10 in (254 mm) long. It is possible to compact workpieces that are between 0.0625 in (1.59 mm) and 5 in (127 mm) thick and 0.0625 in (1.59 mm) to 40 in (1,016 mm) long.  Picture of aluminum iron alloys produce process:

Picture of aluminum iron alloys produce process:

Our main products list: 01 Metal Injection Molding

Our main products list: 01 Metal Injection Molding

> Stainless steel: SUS316L,SUS304L,SUS440C,SUS630,17-4PH

> Tungsten alloy: WNiFe,WuNiCu

> Iron-base alloy:

> Hard metal alloy: WC

> Tool steel : M2,42CrMo4

> Soft magnet

02 Powder Compaction Molding

> Copper alloy

> Iron alloy

> Hard metal alloy

03 Bonded NdFeB Magnet

04 Sintered NdFeB Magnet

05 Ferrite

> Sintered Hard Ferrite

> Soft Ferrite-MnZn ferrite

> Soft Ferrite-NiZn ferrite

> Rubber Ferrite

06 others

> SmCo

> Cast and Sintered AlNiCo

> Die Casting Our factory and equipments:

Certification:

Certification:  aluminum iron alloys produce process

aluminum iron alloys produce process

Picture of aluminum iron alloys produce process:

Picture of aluminum iron alloys produce process:

Our main products list: 01 Metal Injection Molding

Our main products list: 01 Metal Injection Molding> Stainless steel: SUS316L,SUS304L,SUS440C,SUS630,17-4PH

> Tungsten alloy: WNiFe,WuNiCu

> Iron-base alloy:

> Hard metal alloy: WC

> Tool steel : M2,42CrMo4

> Soft magnet

02 Powder Compaction Molding

> Copper alloy

> Iron alloy

> Hard metal alloy

03 Bonded NdFeB Magnet

04 Sintered NdFeB Magnet

05 Ferrite

> Sintered Hard Ferrite

> Soft Ferrite-MnZn ferrite

> Soft Ferrite-NiZn ferrite

> Rubber Ferrite

06 others

> SmCo

> Cast and Sintered AlNiCo

> Die Casting Our factory and equipments:

Certification:

Certification:  aluminum iron alloys produce process

aluminum iron alloys produce process Send your inquiry to this supplier

Send Inquiry