1 / 2

Stainless Steel Cutting Machine Drywall Production Machine

| Model No. : | TY-Panel |

|---|---|

| Brand Name : | Tianyu |

Product description

Stainless Steel Cutting Machine Drywall Production Machine

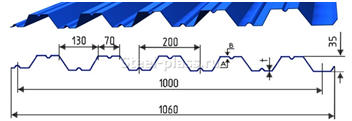

1.Roll Forming Machine Specification

1.Dimensions 7000*1350*1200mm

2.Large frame 300H steel

3.Rolling wheel Forging 45# steel

4.Diameter of roller 75mm with conditioning

5.Roller station 15 rows

6.Main power 4kw with reducer

7.Pump station 4KW

8.Rolling speed 10-12m/min

9.Rolling thickness 0.3-0.8mm

10.Feeding width 1250mm

11.Machine weight 2.5T or so

12.Kind of drive Driving with 1.3 inch chain

13.Middle plate 14mm

14.Chain 1.3 inch

15.Cutting material Cr12

2.Automatic system(The PLC can be designed according to customers' requirement)

Uncoiler

Carrying capacity: 5-7t;

Max coil width: 1.25m

Dimensions: 1.5*1*1m

Operation: Manual

Main body (Reference to the specification of this machine)

Pump Station

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter to work

Power of the oil pump: 4kw

Hydraulic oil :40#

PLC control

Tolerance : within 1.00mm

PLC is Taiwan"Delta"

Frequency converter is Taiwan"Delta"

In Chinese and English interface.

galvanized zinc roof panel deck roll forming machine in Hebei

Platform

Machine and Tile

4.The production process

Decoiling→Active feeding→Leveling→Punching→Roll Forming→Cutting to length→Colletion(Product to stand)5.Service

We provide the technical support for the whole life.

Meanwhile, if any parts go broken and not artificial damage, we will send you new ones for free.

When need the technician to go abroad, we will arrange the technician.But the buyer should take

all the costs, including Visa, Roundtrip ticket,suitable accommodation and pay the service fee to

the technician with $60/day

6.Payment

T/T( 30% by T/T in advance, the rest 70% to be paid by T/T after you inspect the machine

in seller's factory before delivery )

Welome to visit our factory!

FAQ about roll forming machine :

Q:How is this machine's service life?

A:In the normal maintenance,the service life at least 8 years.

Q:How to maintenance?

A:If using frequently,best coating lubricant on the chain and two ends of the shaft every month,replace the hydraulic oil every 1-2 years.

Q:What can you do if the machine broken?

A:Our machine's warranty period is 1 year,if the broken parts can't repair,we can free send the new parts replace the broken parts to you except the solenoid valve,the solenoid valve you must pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

Q:Can you be responsible for transport?

A:Yes,please tell me the destination port or address.we have rich experience in transport.

Q:Mr.Jack,can you make the machine according to my design or proto type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

Q:How many workers operate this machine to manufacture?

A:Only 1-2 worker.

Q:Can you supply the raw materials?

A:Yes,we can supply the galvanized steel coil,galvalume steel coil,color steel coil,and aluminum coil.

Send your inquiry to this supplier