Video

1 / 1

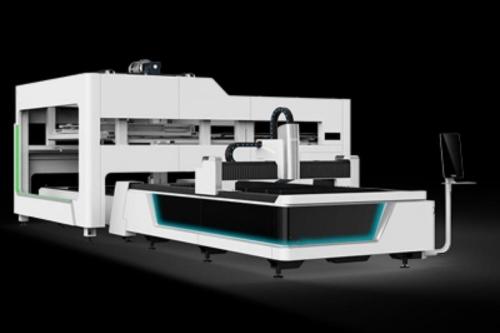

Stainless steel cutting equipment

| Model No. : | 1 |

|---|---|

| Old and new : | New |

Wuxi, Jiangsu, China

- Distributor/Wholesaler

- Gold Supplier

- Platform Certification

- Online Expo

Product description

Stainless steel cutting equipment

The special light curtain for laser protection device of bending machine can be used for plate bending, folding box, z-bending and other forms of workpiece. It is more convenient for users to switch modes by centralizing all functions on the operation panel. Built in power stability module, reverse protection module, overload protection module, suitable for all kinds of bending machine. The light source used is visible light, and the transmitter is used to automatically align the light, even if the bending machine has strong vibration light, which is more convenient. The light curtain adopts a self-determination data processing chip, which automatically corrects the sensitivity of light, and automatically increases the attenuation of light during continuous use. The product is designed for 100000 hours.

CNC bending machine is a kind of forging machinery, the main role is metal processing industry. The products are widely used in light industry, aviation, shipbuilding, metallurgy, instrument, electrical appliances, stainless steel products, steel structure construction and decoration industries. The bending machine is currently the preferred machine for sheet metal processing of sheet metal, especially for large sheet metal. By selecting and matching various molds, the sheet metal can be bent, stretched, pressed, punched, etc. The bending machine can be divided into mechanical and hydraulic. The hydraulic bending machine can be divided into mechanical synchronization, torsional shaft synchronization, mechanical hydraulic synchronization, and electro-hydraulic synchronization. Hydraulic bending machine can be divided into: up moving type, down moving type. The down moving type is that the workpieces on the worktable and the worktable move upward together, and the slide block does not move. At present, it is relatively rare in the domestic market, most of them are up moving. The up moving type is that the workpieces on the worktable and the worktable do not move, and the slide block moves downward. According to the control mode, it can be divided into general control, economic numerical control and standard numerical control.

Carbon dioxide series: Carbon dioxide optical lens, excitation module, high pressure module, turbine, focusing mirror, Bypos mirror, refractor, cutting head, nozzle, ceramic ring, dust cover

Optical fiber series: push in nozzle, protective lens, sapphire lens, ceramic ring, cutting head, cutting head accessories, ipg module, communication module, communication cable, protective cover, various filter elements, pressure reducing valve, nozzle body, quick-insert nozzle body, adaptor 2.0, servo, motor, power supply, CNC rack, HighYAG cutting head, collimator Lens, focusing mirror and more.

Video

Wuxi, Jiangsu, China

- Distributor/Wholesaler

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier