1 / 6

SS2205 Chrome Plated Stainless Steel Rod Piston

| Model No. : | Hydraulic Cylinder Piston Rod |

|---|---|

| Brand Name : | EAST AI |

Product description

Machined Piston Rod for Hydraulic Cylinder:

Machined Piston Rod for Hydraulic Cylinder:  Hollow Piston Rod / Hollow Chrome Bar:

Hollow Piston Rod / Hollow Chrome Bar:

Ceramic Plated Piston Rod:

Ceramic Plated Piston Rod:  Customer Feedback:

Customer Feedback:  Product Description

Product Description | Piston Rod Specification Ceramic, Nickel and Chrome Plated Piston Rods: | |

Material: | CK45, SAE1045, 4140, 4340, JIS45C, 40Cr, 20MnV6, 42CrMo, SS431, SS430, Stainless Steel 304/316/2205, etc. |

Diameter: | Φ 6-500mm |

Length: | max 13m |

Chrome layer: | 20 micron (min) to 100 micron |

Hardness of the chrome layer: | 850 HV (min) - 1150 HV |

Roughness: | Ra <= 0.2u |

Straightness: | <= 0.2/1000 |

Diameter tolerance: | ISO f7/h8/g6 |

Roundness: | Half of the tolerance ISO f7 |

Delivery condition: | Hard Chrome Piston Rod ( HRC 15-20) |

Quenched & Tempered (Q+T) Rod (HRC 28-32) | |

Induction Hardened Rod (HRC 55-62) | |

Q+T Induction Hardened Rod (HRC 60-65) | |

Corrosion resistance: | Test in natural salt spray according to ASTM B 117-96 hours. |

Packing: | Anti-rust oil to be spread on rod surface and each rod to be packed in paper roll and then in wooden case. |

ISO f7 | |||

OD (mm) | Tolerance (mm) | ||

< | <= | <= | <= |

6 | 10 | -0.013 | -0.028 |

10 | 18 | -0.016 | -0.034 |

18 | 30 | -0.020 | -0.041 |

30 | 50 | -0.025 | -0.050 |

50 | 80 | -0.030 | -0.060 |

80 | 120 | -0.036 | -0.071 |

CHEMICAL COMPOSITION (%) | |||||||

Material | C% | Mn% | Si% | S% | P% | V% | Cr% |

<= | |||||||

CK45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0.035 | 0.035 |

|

|

ST52 | <=0.22 | <=1.6 | <=0.55 | 0.035 | 0.035 |

|

|

20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.10-0.50 | 0.035 | 0.035 | 0.10-0.20 |

|

42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 |

| 0.90-1.20 |

4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 |

| 0.80-1.10 |

40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 |

|

|

| 0.80-1.10 |

MECHANICAL PROPERTIES | |||||

Material | T.S. Mpa | Y.S. Mpa | E% | Impact | Condition |

(min) | |||||

CK45 | 610 | 355 | 15 | >39J | Hot Rolled |

CK45 | 800 | 630 | 20 | >41J | Q+T |

ST52 | 630 | 520 | 14 |

| Cold Drawn |

20MnV6 | 750 | 590 | 12 | >40J | Hot Rolled |

42CrMo4 | 980 | 850 | 14 | >47J | Q+T |

4140 | 1080 | 930 | 12 |

| Q+T |

40Cr | 1000 | 800 | 10 |

| Q+T |

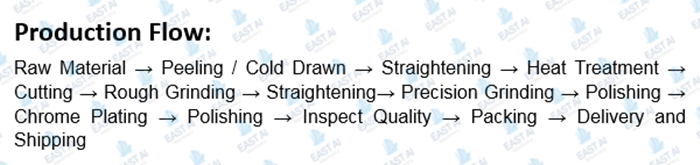

Main Equipment: Peeling Machine ………………………………… 1 Set Cold Drawing Machine… ………………………… 2 Sets Straightening Machine ………………………… 6 Sets Heat Treatment Furnace ……………………… 1 Set Cutting Machine ………………………………… 3 Sets Centreless Grinding Machine ………………… 6 Sets Polishing Machine ………………………………… 6 Sets CNC Machine …………………………………… 5 Sets Special Chrome Plating Mill Quality Control

Main Equipment: Peeling Machine ………………………………… 1 Set Cold Drawing Machine… ………………………… 2 Sets Straightening Machine ………………………… 6 Sets Heat Treatment Furnace ……………………… 1 Set Cutting Machine ………………………………… 3 Sets Centreless Grinding Machine ………………… 6 Sets Polishing Machine ………………………………… 6 Sets CNC Machine …………………………………… 5 Sets Special Chrome Plating Mill Quality Control

Quality Testing Tools: Micrometer ……………………….. (Check Size and Tolerance) Roughness Tester Chrome Layer Tester Universal Testing Machine ……… (Check Mechanical Properties) Spectrograph ……………………... (Check Chemical Composition) Hardness Tester Salt Spray Test Machine MTC & Certificate

Quality Testing Tools: Micrometer ……………………….. (Check Size and Tolerance) Roughness Tester Chrome Layer Tester Universal Testing Machine ……… (Check Mechanical Properties) Spectrograph ……………………... (Check Chemical Composition) Hardness Tester Salt Spray Test Machine MTC & Certificate  Packaging & Shipping

Packaging & Shipping  Advantages Reliable Quality & Competitive Price! Place your trust in us! 1. Extensive production experience: start from 2005 in manufacturing honed tube, chrome plated rod and hydraulic cylinders. In Australia, Thailand, Brazil, India, Iran, Indonesia and South Africa we have long-term buyers. Most workers have 8-10 year experience, the oldest have 25 year experience. 2. Advanced production equipment: cold drawing machine (2 sets), honing machine (10 sets), skiving & roller burnishing machine (2 sets), straightening machine (6 sets) , polishing machine (6 sets) , heat treatment furnace (1 set), centerless grinding machine (6 sets), CNC Machine (5 sets) etc. Our technicians will do regular scheduled maintenance on these machines to guarantee them work well. 3. High quality raw material: we mainly choose raw material from big steel factory, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China. 4. Quality Standard: Honed Tube, inside surface roughness 02-0.4 um, straightness max 0.5/1000, ID tolerance DIN2391 H8. Skived & Roller Burnished Tube, inside surface roughness under 0.2 um, straightness max 0.2/1000, ID tolerance DIN2391 H8. Chrome Plated Rod, chrome layer min 20 microns, OD tolerance ISO f7. 5. Delivery time fast: If one container 15-20days. We also stock some standard size tubes and rods, if you need 3-5 pcs, we can delivery soon. 6. Strict quality control: we have professional in-house QC person to inspect all products, and will do chemical composition test, mechanical property test, dimension inspect, roughness test, chrome layer test and other tests in need before delivery. QC department will provide test reports and MTC for each order, and all reports will be keep 3-5 years. 7. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube. Finally be packed with seaworthy package or in wooden case. 8. Best after-sale service: each order from production to delivery will be follow up in time and keep customer updated. 9. Competitive price and reliable quality. 10. OEM service and third party certificate can be provided. Company Information

Advantages Reliable Quality & Competitive Price! Place your trust in us! 1. Extensive production experience: start from 2005 in manufacturing honed tube, chrome plated rod and hydraulic cylinders. In Australia, Thailand, Brazil, India, Iran, Indonesia and South Africa we have long-term buyers. Most workers have 8-10 year experience, the oldest have 25 year experience. 2. Advanced production equipment: cold drawing machine (2 sets), honing machine (10 sets), skiving & roller burnishing machine (2 sets), straightening machine (6 sets) , polishing machine (6 sets) , heat treatment furnace (1 set), centerless grinding machine (6 sets), CNC Machine (5 sets) etc. Our technicians will do regular scheduled maintenance on these machines to guarantee them work well. 3. High quality raw material: we mainly choose raw material from big steel factory, such as TPCO, BAO STEEL, SHA STEEL, which are best and largest raw material manufacturer in China. 4. Quality Standard: Honed Tube, inside surface roughness 02-0.4 um, straightness max 0.5/1000, ID tolerance DIN2391 H8. Skived & Roller Burnished Tube, inside surface roughness under 0.2 um, straightness max 0.2/1000, ID tolerance DIN2391 H8. Chrome Plated Rod, chrome layer min 20 microns, OD tolerance ISO f7. 5. Delivery time fast: If one container 15-20days. We also stock some standard size tubes and rods, if you need 3-5 pcs, we can delivery soon. 6. Strict quality control: we have professional in-house QC person to inspect all products, and will do chemical composition test, mechanical property test, dimension inspect, roughness test, chrome layer test and other tests in need before delivery. QC department will provide test reports and MTC for each order, and all reports will be keep 3-5 years. 7. Safe packing: anti-rust oil be spread on tubes and rods before shipping, plastic caps on tube ends to protect inside surface, each rod be protected with cardboard tube. Finally be packed with seaworthy package or in wooden case. 8. Best after-sale service: each order from production to delivery will be follow up in time and keep customer updated. 9. Competitive price and reliable quality. 10. OEM service and third party certificate can be provided. Company Information  Direct Line: 0086-510-66881071 Skype: ea.machinery WELCOME YOU VISIT OUR FACTORY! WELCOMR YOUR INQUIRY AND ORDER! THANK YOU FOR DOING BUSINESS WITH EAST AI MACHINERY!

Direct Line: 0086-510-66881071 Skype: ea.machinery WELCOME YOU VISIT OUR FACTORY! WELCOMR YOUR INQUIRY AND ORDER! THANK YOU FOR DOING BUSINESS WITH EAST AI MACHINERY! Send your inquiry to this supplier