1 / 2

Solid Silicone O Ring Molding Equipment

$10000.00

≥1 Set/Sets

| Model No. : | JY-A02 |

|---|---|

| Brand Name : | JINYU |

| Feature : | High Efficiency |

Dongguan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Product description

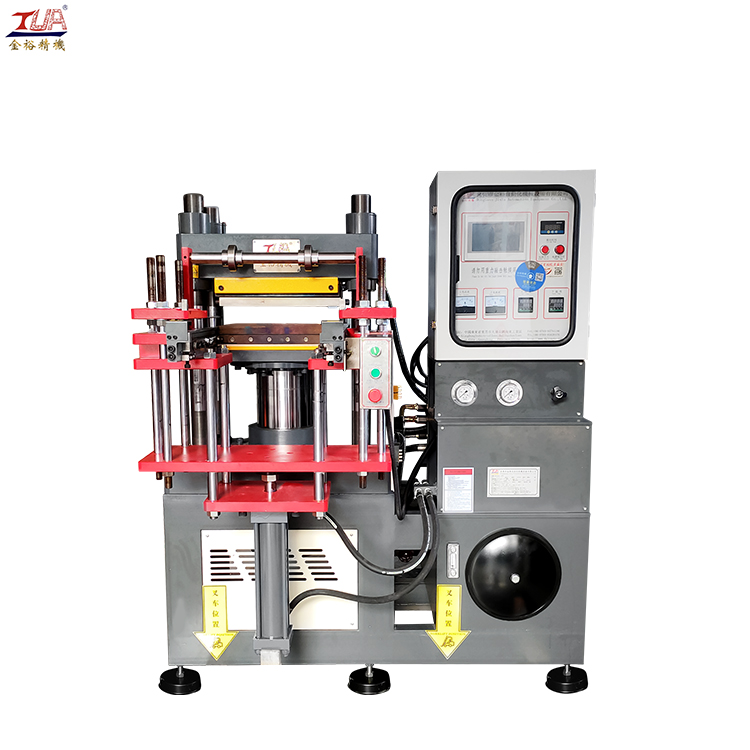

Solid Silicone O Ring Molding Equipment

The silicone o ring molding equipment mainly for making the solid silicone rubber products, including the oil seal, swimming cap, cake mold, watchband, bracelet, mobile phone case, USB case, keychain, and so on. the formal top: automatic opening the mould, convenient and save effort.

The pillar: use the chromium, it's very durable without distortion

The push button: including automatic button manual button and emergency stop button, it means you can choose automatically or manually to complete the task.

Solenoid valve: control the circuit.

Specification:

Model

JY-A02

Clamping force Ton

63

Locking mold

pressure

200

Stroke MM

250

Main cylinder

diameter MM

200

Horse power HP

3.7

Electrical power KW

18.3

Gross weight KG

2000KG

Type of mold

opening

Up and down

Working table size

MM

400*400

Machine size MM

1400*1650*1550

Description:

1. Adopt the world advanced SOLIDEWORK3D software and finite element analysis of mechanical design, the optimum design is integrally molded high rigidity, precise structure, long service life.

2. Heating plate adopt deep hole processing, and after carburizing,after grinding nit-riding, using the principle of heat, get the high precision, and the optimal design with average temperature, HRC50-55 hardness, long time wear-resisting, Not easy to be out of shape and it has high plane precision.

3. Using the technology of planar pressure correction, the maximum pressure(200KG) nut leveling device,the highest plane precision can reach 0.05 MM.

4. Unique oil circuit design, the oil circuit non impact and low noise in operation, increase the effectiveness, reduce the energy consumption.

5. Using circulation radiation cooling device, to ensure good heat exchange, low oil temperature, long life hydraulic parts, stability forming.

6. Intelligent PID control output, the difference of set temperature and actual temperature controlled in+-1 degree. It is economic and energy-saving.

7. Importing the latest digital prototype testing technology, higher thermal performance, better stability than the traditional design.

8. Adopt imported famous brand digital temperature control, the precision of temperature controlled in +-2 degrees the program has a week preheating function.

Our Factory View:

Package:

Dongguan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier