1 / 2

Snap locking standing seam roll forming machine

| Model No. : | snap locking standing seam |

|---|

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

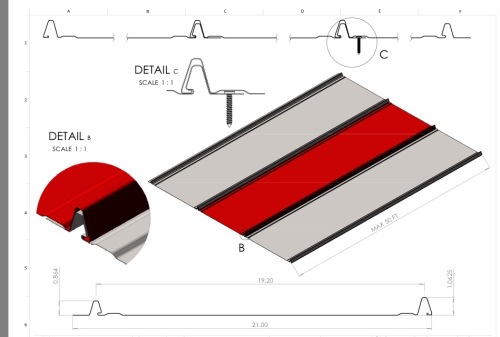

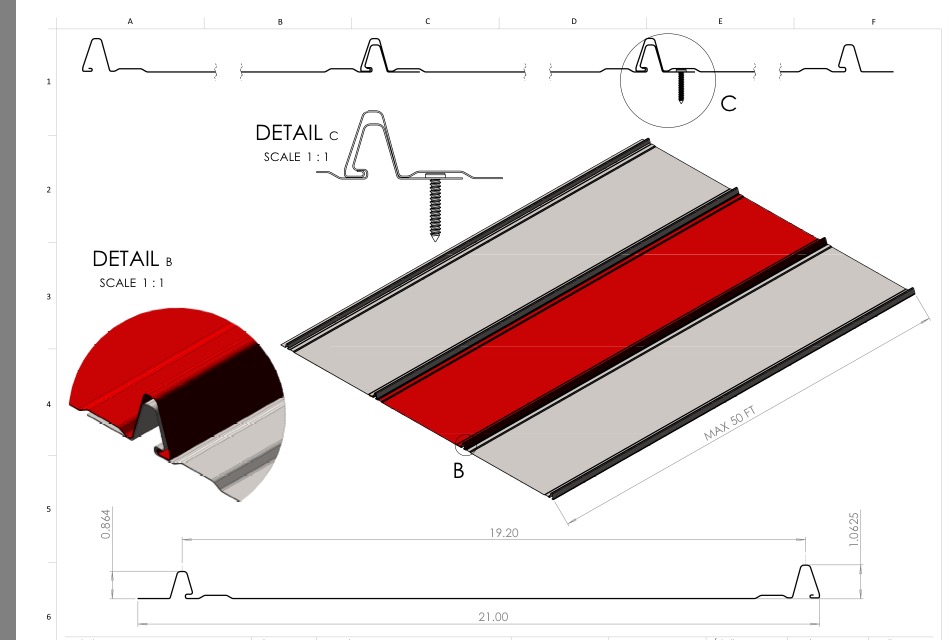

Snap locking standing seam roll forming machine

Snap-Lock standing seam Roofing Panel no need seaming and cliper.It is composed of manual decoiler,main forming mart,automatic cutting,collecting table.It is now a stronger and more durable panel which withstands the extreme weather that wreaks havoc on most roofs. This panel is available in both 26 and 24 gauge and is custom produced in the factory with 10 popular colours and 2 sizes, 12" and 16".

Our snap locking standing seam roll forming machine can be used a workshop.

The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously.Clip lock standing seam machine and nail strip standing seam roof machine are very popular for now.Any inquiry just contact us.

Parameters of raw material

| Material | Thickness | I.D | Yield Strength |

|

Q235 gi&ppgi& galvalume |

0.25-0.7mm | 508mm | <=235mpa |

2.Photos of Machine:

The weight of machine is about3.1tons.The total dimension of machine:6800(L)*1200(W)*1500mm(H)

3.1Manual decoiler:

Capacity of uncoiler:5tons

Expansion of segment:Manual

Rotation of segment:Manual

Number of segment:4

Range of segment expansion:480-520mm

Operation method:Manual

Qty: 1

3.2 Guiding system:

To keep the material straight

Entrance and adjustable wheel: 2rolls

Qty: 1

3.3Main forming machine:

Coil thickness:0.25-0.7mm

motor type: 3 phase asynchronous motor

Main motor power:4kw+3kw(normal speed),

Approx.18groups roller including

Roller : S45C with quenching treatment,Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

Shaft:Diameter of max shaft: ø70mm(hardening and tempering)

Transmission type:by one inch chain

Qty: 13.4 Hydraulic cutting:

Material of blade: Cr12Mov,HRC58-62

Length measuring: Automatic encoder length measuring

Type of cutting:Cutting after forming:Cut the sheet after roll forming to required length.No need to change mold for different sizes

Cutting motion:The main machine automatically stops and the cutting will take place.After the cutting,the main machine will automatically start.

Power of motor:3kw

3.5 Product support frame

Size: L 3m x W0.5m

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier