1 / 5

Small Central Mix Concrete Batch Plant

| Model No. : | HZS35 |

|---|---|

| Brand Name : | We need it for you all |

| Type : | Concrete Mixing Plant |

Harbin, Heilongjiang, China

- Manufacturer

- Trade Company

- Platform Certification

- SGS Certification

- Online Expo

Product description

Small Central Mix Concrete Batch Plant

Product description

HZS35 concrete mixing plant is used for mixing commodity concrete and concrete construction in different kind of architectural project, including the water conservancy, the electric power, the railroad, the road, the tunnel, the arch of bridge, the harbor-wharf and the national defense-project and so on, the applicable scope of HZS35 stationary concrete batching plant is extremely wide spread.

HZS35 concrete mixer plant can mix the hard concrete, plastic concrete, liquid concrete, and various other lightweight aggregate concrete.

The HZS35 concrete plant operational model include fully automatic, semi-automatic and manual type.

Features of Hopper Lift Concrete Mixing Plant

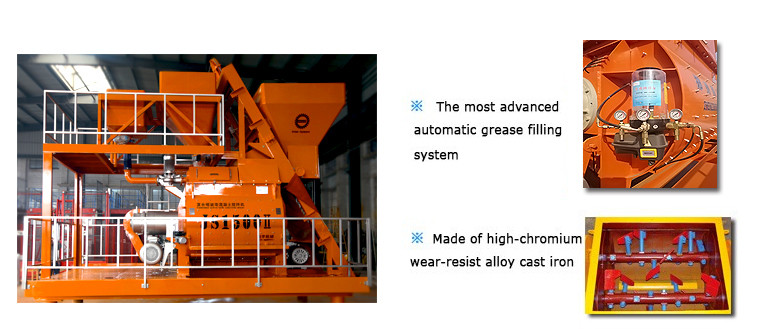

1. HZS35 concrete mixing plant adopts JS750 twin shaft horizontal concrete mixer with superior efficiency and high energy-saving.

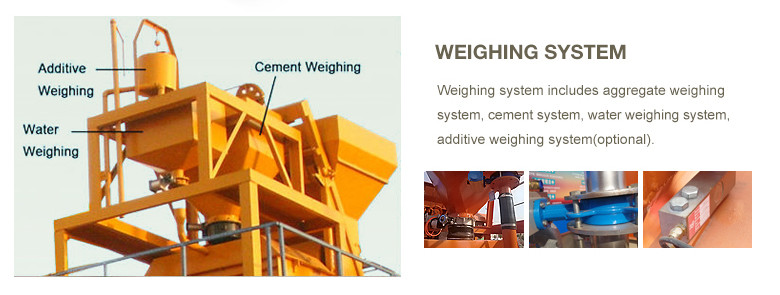

2. The electronic weighting system of HZS35 concrete batching plant has a buffer device and automatic volume compensation with high accuracy.

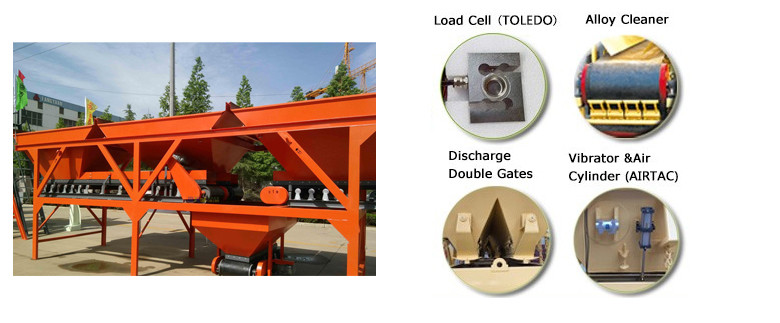

3. Sand & gravel batching machine use PLD1200 with has highly accuracy measuring.

4. Equipped with maintenance walkway, engineer can examine HZS35 stationary concrete mixing plant timely and easily.

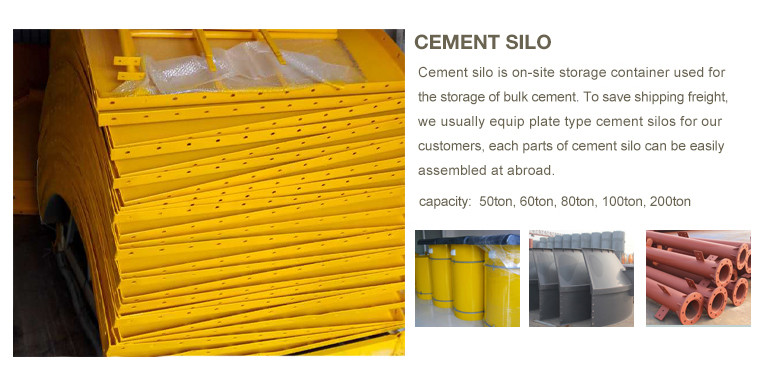

5. Cement is stored in cement silo and delivered by concrete screw conveyor.

6. Water supply system is composed by water tank, water pump and water weigh.

HZS35 concrete batching plant is operated by PLC fully automatic control system. All the mixing and batching systems run automatically.

Technical Parameters of Lifting Hopper Concrete Mixing Plant

Model

HZS25

HZS35

HZS50

HZS75

Capacity

25m3/h

35m3/h

50m3/h

75m3/h

Mixing system

Twin shaft concrete mixer

Aggregate feeder

Bucket (Skip hopper)

Discharging height

1500-3800mm

3800mm

3800mm

3800mm

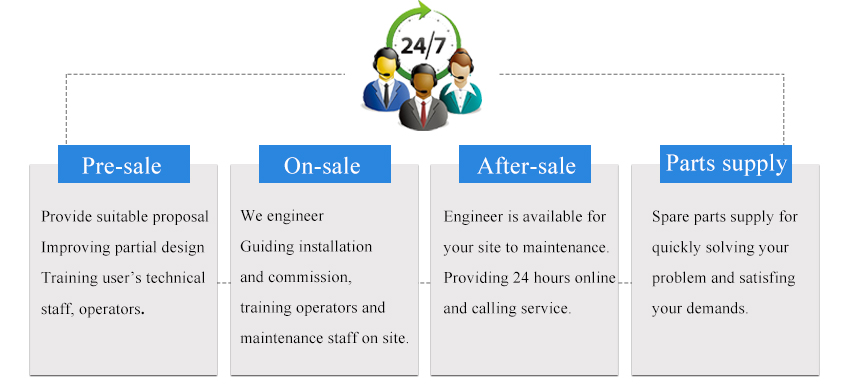

After-sale service

Erection & commissioning, operator training

Warranty

12 months after erection

Concrete mixer

JS500

JS750

JS1000

JS1500

Discharging volume

500L

750L

1000L

1500L

Charging volume

800L

1200L

1600L

2400L

Mixing circle

72s

Max. mixing size

80/60mm

Aggregate batching machine

PLD800

PLD1200

PLD1600

PLD2400

Storage bins quantity

2 or 3 or 4 sorts

3 or 4 sorts

3 or 4 sorts

3 or 4 sorts

Aggregate scale hopper

800L

1200L

1600L

2400L

Weighing system

Water, Cement, Additive

Weighing precision

±1%

Air system

Air compressor, etc

Control system type

Computer auto-control module (PLC can be optional item)

Packaging&Shipping of Our Products

Our Service

1.According to your inquiry, the first time to give the offer, the first time to give production.

2.Best After-sales: We will send the technical personnel to the site for installation, commissioning and training work.

3.Warranty period 12 Months, in addition to the force majeure and man-made factors, the damage caused by design, process and manufacturing equipment, the seller is responsible for sending people to offer free repair.

4.We will send the spare parts of concrete mixer plant as soon as possible when necessary, equipment repair parts provided by the seller are original, authentic, quality goods.

Harbin Zephyr Trading Co.,Ltd locates in the north of China, province Heilongjiang,city Harbin.This is an international trading company mainly exports large road machinery such as:asphalt mixing plant,concrete mixing plant,crusher,crushing and screening production line,excavator,bulldozer,loader,dump truck,truck crane,concrete mixer truck and so on...

As one of the first professional supplier of asphalt mixing plant and concrete mixing plant in China,we have always given attention to maintaining our higher level quality control and service , and we have received the ISO9001,CE,SGS etc certificates.Our equipment has exported to 35 countries,including:Russia,India,Bangladesh,Ghana etc.

If you have any inquiry about the concrete mixing plant or constructions machinery,please fell free to contact us,We are always warmly welcome you to come and look forward to our meeting!

FAQ

DO YOU SELL WET OR DRY CONCRETE BATCHING PLANTS, STATIONARY OR MOBILE?

Yes, we can offer both wet and dry concrete batching plants, and stationary type and mobile type are both available.

I NEED ADVICE ON THE CORRECT EQUIPMENT TO USE, CAN YOU ADVISE ME?

Yes, our professional technical team will be happy to understand your needs and advise on your best options.

DO YOU STOCK SPARE PARTS?

Yes, we have a dedicated team for all spare and service part enquiries and we endeavour to keep parts for all our equipment in stock for next day delivery (48 hours for international customers).

WHAT HAPPENS IF MACHINE BREAKING DOWN OR REQUIRING HELP AND SUPPORT?

We have mobile engineers that are available for call outs. Alternatively support by phone or email is available 24/7.

Whar 's your after-sale service?1, 12 months warranty from products departure. Enough spare parts and quick-wear parts sent together.

2, Onsite installation, debugging, workers training. Make sure that your workers operate properly and know daily maintenance well.

3, Prompt reply in case of any problems.

What`s the service life of your machinery?

Usually 5-10 years under good maintenance.

How soon can you reply me?

In 1 working day, detailed quotation and program design will be offered.

What`s your delivery time?

5 days for single machines, 15 days for plants.

What are your payment terms?

T/T, L/C, Paypal, Credit card, Western union, Moneygram are all ok.

Contact Us

If interested in our products, please contact with us without hesitation.

We are waiting for your message. ↓↓↓

Harbin, Heilongjiang, China

- Manufacturer

- Trade Company

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier