1 / 1

Small Industries Use Automatic Cement Brick Molding Machine

| Model No. : | QTJ4-35 |

|---|---|

| Brand Name : | sanxiong |

Product description

Small Industries Use Automatic Cement Brick Molding Machine

1. Production Introduction of QTJ4-35:

QTJ4-35 mechanical stripping brick block machine is designed by Sanxiong Heavy Industry Co., Ltd according to China's small and medium sized hollow block machine`s design specification, strong stability, resistance to wear.

Install a travel switch, greatly improving the product quality, with the characteristics of easy operation, high pressure, good performance, and it is equipped with electromagnetic brake motor effectively eliminate aftershocks, greatly improving the production efficiency, both save work and save electricity, small investment, quick effect, so it is small and medium-sized investors preferred ideal models.

2. Production features of QTJ4-35:

1, QTJ4-35 baking-free mechanical stripping brick block machine body are all made of high strength steel and special welding technology manufacturing, achieve to situation of the welding cracking not easily open, extremely strong and durable;

2, pressure head downward adopts worm gear speed reducer drive technology to achieve smooth downward; Head down adopts the four gear rack occlusal technology to molding brick height unification, edges tidy and beautiful, and not easy to damage the mold box. Pressure head with two adjustable vibrator to offer the required vibration force for producing different bricks.

3, the feeder box adopts double rack propulsion technology, marching with closed the container door to achieve the whole machinery complete, simple structure, be clear at a glance, stability production, easy to maintenance.

4, the up and down of the mould box adopts lifting the arms chain bar pusher technology to achieve balance in sync, marching slide smoothly, don't damage the sliding sleeve and sliding axis.

5, vibration platform adopts the washboard type cast steel technology to encrypt the amplitude, the average distribution of vibration force, fully make force converge in vibration platform, increase the density of the bricks, high strength. At the same time, it reduced the dispersion force destructive to the body.

6, the points' teeth and the rotation axis of the feeder box with 360 degree rotation technique to force the feeding, the effect is fast feeding, and very uniform.

7, electric control cabinet using automatic and manual two panels for a cabinet in production technology, to achieve automatic panels under the condition of sudden fault, immediately knob to manual panels, the production can be continued to carried out. The purpose is non-stop after starting up to guarantee the normalization of production, in order to improve work efficiency.

8, the storage bin adopts slidable before and after technology to facilitate cleaning feeder box.

9, both frame and the mould adopt carbon dioxide protection welding technology to achieve strong firm, not fried, not crack, not deformation, greatly extend the service life.

3. Special design of QTJ4-35:

1, all the body made of strong square steel welding, extremely strong resistance to vibration stability performance is very good.

2, the mould box adopts double column sliding, with compact and stable synchronization up and down, and block forming rate is greatly increased.

3, pressure head can slide displacement, it is convenient for molding box to feeding, greatly improve work efficiency.

4, the mould box installation of limited position switch, is expected to avoid pressure head damaged machine in action.

5, when vibration used up, before and after in synchronization vibration, the mould box walls get the uniform stress, achieve to the best molding effect, ensure the bricks high strength compactness, clean edges and corners, pallet after forming.

4. Technical Parameter of QTJ4-35:

|

Overall size |

10000x3600x2750mm |

|||

|

Carriage size |

880x450x25mm |

|||

|

Cycle |

40 seconds |

|||

|

Electrical source |

380v/50 Hz |

|||

|

Forming Number |

8 pcs/mold 240*115*53(min) |

|||

|

Power Rating |

4.8 kW |

|||

|

Weight |

0.7t |

|||

|

Capacity |

300-2500pcs/h |

|||

|

Cutting specifications |

Forming number |

Forming cycle |

Capacity(8 hour) |

|

|

390*190*190 |

4 pieces |

35-40s |

2800-3000pcs |

|

|

390*240*190 |

3 pieces |

35-40s |

2200-2500pcs |

|

|

240*115*90 |

9 pieces |

35-40s |

6000-6500pcs |

|

|

240*115*53 |

24 pieces |

35-40s |

20000pcs |

|

Any change of the technical data shall not be advised additionally.

5. Brick Samples of QTJ4-35:

We can also produce the size according to your requirements, the followed samples` picture are some of our products for your reference.

6. Raw Materials of QTJ4-35:

The raw materials can be sand, stone powder, fly ash, cement, slag, etc., the followed picture is some of the stone powder for your reference.

7.Machine Pictures of QTJ4-35:

Packaging and shipping:

Service

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, plant, the condition of build factory, feasibility analysis for charcoal production line ```)

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick)

(3) 24 hours service

(4) Welcome to visit our factory and production line anytime

(5) Introduce the company file, product categories and production process.

(6) OEM design

Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale:

(1) The engineer will guide to carry out the plant at the clients side.

(2) Set up, fix,and operate

(3) Will not train the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time,keep well communication with each other.

Henan Sanxiong Heavy Industry Co., Ltd. was built in 1984, having been specialized in the development, research and production of new building materials equipment for almost 38 years. We have successfully installed and debugged whole brick press machine production lines, automatic hydraulic block making machine production lines and clay brick making machine production lines, and charcoal machine for customers at home and abroad.

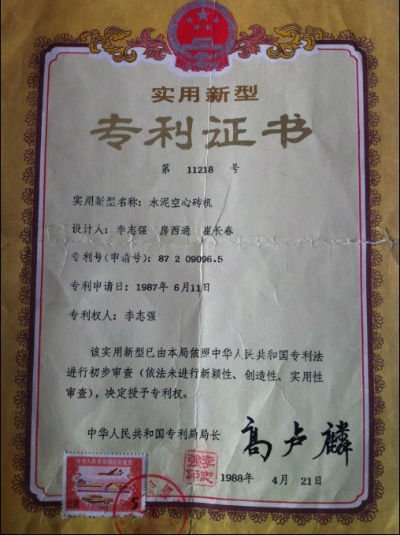

Our products have achieved ISO9001:2000 certificate, National patent products, also won a series of national and local technical award certificates. Our products have been sold to Middle East, Russia, Australia, South Asia, South Africa, West Africa and other Areas.

Q: what is no burning brick making machine ?

A : No burning brick making machine is a term for brick machinery .It is different from the traditional kiln brick processing .It make bricks by pressure, no need fire.

Q. what is MZJ360-3 and MZJ600-3 ?

A: MZJ360-3 and MZJ600-3 are two models of un burnt brick making machine, 360 and 600 mean the mechanical pressure for 360ton and 600ton. and 3 means:3 piece of bricks per mold. Is combined with the current domestic and foreign similar characteristics and also marketing needs to design and manufacture of new brick making equipment, has a compact structure, high pressure, strong rigidity ,easy operation, high output, durable in use characteristics.

Q: What is different from MZJ360- 3 and MZJ600-3 ?

A : The raw material made by MZJ600-3 is more widely than MZJ360-3, and the strength of bricks made by MZJ600-3 is higher than bricks made by MZJ360-3;

MZJ600-3 with higher pressure than MZJ360-3; MZJ600-3 with 600 ton mechanical pressure ,and MZJ360-3 with 360 ton mechanical pressure;

MZJ600-3 with higher output capacity than MZJ360-3; MZJ600-3 with capacity is: 3600-4000 bricks per hour, and MZJ360-3 with capacity is 3200-3600 bricks per hour;

The main machine of MZJ600-3 twice as weight as main machine of MZJ360-3 ;

MZJ600-3 adopted the stainless steel in 50mm and MZJ360-3 adopted the stainless steel in 30mm;

Q: what is the pressuring way of your machine?

A: Shacking together with the double sided high pressuring;

Q: what is the raw material of making bricks,and what is the ratio method ?

A: Sand ,river sand, slag, coal gangue, stone powder, fly ash, cement,Construction waste, clay and so on ;

Ratio method:

Fly ash + stones powder +cement;

Fly ash + construction waste + cement;

Construction waste + cement;

Sand + lime + cement;

Sand + stones powder + cement;

Sand + clay + cement;

Clay +cement;

Clay

(According to your real situation )

Q: what is the output capacity of your brick making machine, and what is the size specification of bricks?

A:Solid bricks, hollow blocks, blind hole bricks, paving bricks and so on.

Standard bricks in China: 240*115*53 with capacity:

MZJ360-3:3200-3600 bricks per hour, that is 25600-38800bricks per day(8hrs);

MZJ600-3:3600-4000 bricks per hour, that is 28800-32000bricks per day(8hrs)

Also: 230*62*115; 230*45*115; 225*56*112; 230*75*115; 230*52*115; 230*65*115; 225*47*56; 225*56*47 and so on .

we can do many different of bricks or blocks by changing the mold ,the output capacity will be a little different .

Q: What is the quality and strength of the brick?

A: First,we have developed a new type of mixer for the brick making machine, it will grind the material when it is mixing the material. and in this way, we make the material mixed uniformly ,improved the density of the brick, and for no gas barrier and the pressure of the brick making machine is 360t and 600t ,so we make the brick more strength, and the pressure every brick can bear is more than 10Mpa for every square centimeter. And a man can stand on the brick which was made just now, the brick can be can be also directly stacked 10-12 layer.

Q: What is the application of the brick?

A: Bear wall, Isolation wall

Q: What is the size of the brick?

A: Standard bricks, hollow bricks, blind hall, and we can make the bricks as your order.

Tel: +86-18937118667

Mob.: +86-15824625391

QQ: 1829603653

Send your inquiry to this supplier