1 / 4

Sludge Suction Pump,Small Sludge Pump

Get Latest Price

Send Inquiry

| Model No. : | NH |

|---|---|

| Brand Name : | NNT |

Shijiazhuang Nainate Screens Pump Co., Ltd.

You might also like

Product description

Sludge Suction Pump,Small Sludge Pump  Paramters Size range (outlet):----- 1'' to 18'' (25 mm to 450 mm) Capacity:-------------- up to 22,000 gpm ( 5,000 m3/hr ) Head: -----------------up to 240 ft (73 m ) Pressure: --------------up to 300 psi (2,020 kPa) Overview NNT BRAND Type of NH series centrifugal slurry pumps are cantilevered,horizontal,slurry pumps. 1. They are designed for the handling highly abrasive, high density slurry in the metallurgical, mining, coal, power, building material and other industrial departments etc. 2. The pumps of this type also can be installed in multistage series. 3. The frame plates for type NH centrifugal slurry pumps have replaceable wear-resistant metal liners or rubber liners. 4. The impellers are made of wear resistant chrome alloy or rubber. 5. The frame plate liner and impeller for HH pump are adoptable of wear-resistant metal only . 6. The shaft seals for type NH centrifugal slurry pumps can be adoptable of gland seal or expeller seal. Structure

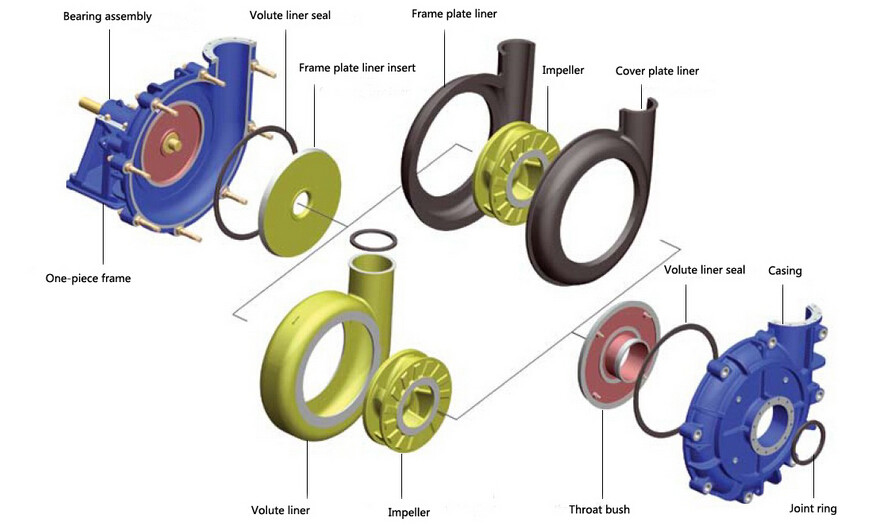

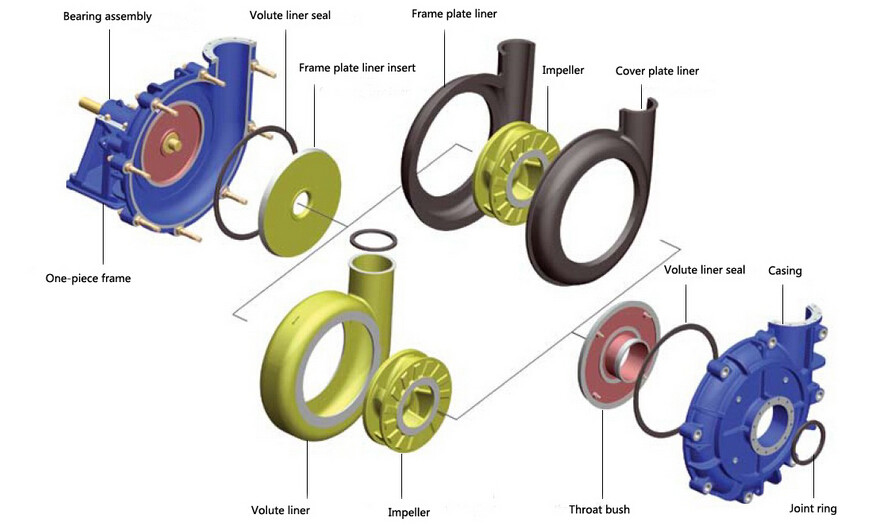

Paramters Size range (outlet):----- 1'' to 18'' (25 mm to 450 mm) Capacity:-------------- up to 22,000 gpm ( 5,000 m3/hr ) Head: -----------------up to 240 ft (73 m ) Pressure: --------------up to 300 psi (2,020 kPa) Overview NNT BRAND Type of NH series centrifugal slurry pumps are cantilevered,horizontal,slurry pumps. 1. They are designed for the handling highly abrasive, high density slurry in the metallurgical, mining, coal, power, building material and other industrial departments etc. 2. The pumps of this type also can be installed in multistage series. 3. The frame plates for type NH centrifugal slurry pumps have replaceable wear-resistant metal liners or rubber liners. 4. The impellers are made of wear resistant chrome alloy or rubber. 5. The frame plate liner and impeller for HH pump are adoptable of wear-resistant metal only . 6. The shaft seals for type NH centrifugal slurry pumps can be adoptable of gland seal or expeller seal. Structure  Details 1. The wet parts for slurry pump are made of wear-resistant high chromium alloy. 2. Slurry pump's bearing assembly use cylindrical structure, adjusting the space between impeller and front liner easily. They can be removed completely when being repaired. Bearing assembly use grease lubrication. 3. The shaft seal could use the packing seal, expeller seal and mechanical seal.

Details 1. The wet parts for slurry pump are made of wear-resistant high chromium alloy. 2. Slurry pump's bearing assembly use cylindrical structure, adjusting the space between impeller and front liner easily. They can be removed completely when being repaired. Bearing assembly use grease lubrication. 3. The shaft seal could use the packing seal, expeller seal and mechanical seal.  4. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. 5. There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices for the slurry pump. 6. Wide performance, good NPSH and high efficiency. The slurry pump can be installed in multistage series to meet the delivery for long distance.

4. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. 5. There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices for the slurry pump. 6. Wide performance, good NPSH and high efficiency. The slurry pump can be installed in multistage series to meet the delivery for long distance.  1). Cantilever, horizontal centrifugal slurry pump 2). Better wear-resistance and corrosive resistance 3). Frame plate for type pumps have replaceable wear-resistant metal ( high chrome alloy ) liners or rubber liners. Impeller material : high chrome alloy or Natural rubber . 4). In allowable pressure range, it can be used in series in stages, and allowable maximum working pressure is 3.6Mpa. 5). Expeller seal, mechanical seal and packing seal are available . 6). The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications. 7). To adapt to convey heavy abrasion, high concentration dreg , slurry pump's body is used double-deck construction , in other words, being made of inside lining and outside shell.

1). Cantilever, horizontal centrifugal slurry pump 2). Better wear-resistance and corrosive resistance 3). Frame plate for type pumps have replaceable wear-resistant metal ( high chrome alloy ) liners or rubber liners. Impeller material : high chrome alloy or Natural rubber . 4). In allowable pressure range, it can be used in series in stages, and allowable maximum working pressure is 3.6Mpa. 5). Expeller seal, mechanical seal and packing seal are available . 6). The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications. 7). To adapt to convey heavy abrasion, high concentration dreg , slurry pump's body is used double-deck construction , in other words, being made of inside lining and outside shell.

For example: 6/4E-NH 6:------------Suction diameter (inch) 4:------------Discharge diameter (inch) E:-----------Base type NH:---------Heavy abrasive slurry pump

For example: 6/4E-NH 6:------------Suction diameter (inch) 4:------------Discharge diameter (inch) E:-----------Base type NH:---------Heavy abrasive slurry pump

This Series of Pumps are used conveying abrasive or corrosive slurry, especially clinker of power plants in electric power, metallurgy, mining, coal, building materials, chemical industry and other industrial sectors,etc.

This Series of Pumps are used conveying abrasive or corrosive slurry, especially clinker of power plants in electric power, metallurgy, mining, coal, building materials, chemical industry and other industrial sectors,etc.

Shijiazhuang Nainater Slurry Pump Co., Ltd (NNT Pump) Website: http://www.nntpump.com Address: No.1, Tianshan Street, Hi-tech Zone, Shijiazhuang City, Hebei Province, China If you have any questions ,please feel free to contact with me via Trade Manager , Skype or Email . We will reply within 12 hours .

Shijiazhuang Nainater Slurry Pump Co., Ltd (NNT Pump) Website: http://www.nntpump.com Address: No.1, Tianshan Street, Hi-tech Zone, Shijiazhuang City, Hebei Province, China If you have any questions ,please feel free to contact with me via Trade Manager , Skype or Email . We will reply within 12 hours .

Paramters Size range (outlet):----- 1'' to 18'' (25 mm to 450 mm) Capacity:-------------- up to 22,000 gpm ( 5,000 m3/hr ) Head: -----------------up to 240 ft (73 m ) Pressure: --------------up to 300 psi (2,020 kPa) Overview NNT BRAND Type of NH series centrifugal slurry pumps are cantilevered,horizontal,slurry pumps. 1. They are designed for the handling highly abrasive, high density slurry in the metallurgical, mining, coal, power, building material and other industrial departments etc. 2. The pumps of this type also can be installed in multistage series. 3. The frame plates for type NH centrifugal slurry pumps have replaceable wear-resistant metal liners or rubber liners. 4. The impellers are made of wear resistant chrome alloy or rubber. 5. The frame plate liner and impeller for HH pump are adoptable of wear-resistant metal only . 6. The shaft seals for type NH centrifugal slurry pumps can be adoptable of gland seal or expeller seal. Structure

Paramters Size range (outlet):----- 1'' to 18'' (25 mm to 450 mm) Capacity:-------------- up to 22,000 gpm ( 5,000 m3/hr ) Head: -----------------up to 240 ft (73 m ) Pressure: --------------up to 300 psi (2,020 kPa) Overview NNT BRAND Type of NH series centrifugal slurry pumps are cantilevered,horizontal,slurry pumps. 1. They are designed for the handling highly abrasive, high density slurry in the metallurgical, mining, coal, power, building material and other industrial departments etc. 2. The pumps of this type also can be installed in multistage series. 3. The frame plates for type NH centrifugal slurry pumps have replaceable wear-resistant metal liners or rubber liners. 4. The impellers are made of wear resistant chrome alloy or rubber. 5. The frame plate liner and impeller for HH pump are adoptable of wear-resistant metal only . 6. The shaft seals for type NH centrifugal slurry pumps can be adoptable of gland seal or expeller seal. Structure  Details 1. The wet parts for slurry pump are made of wear-resistant high chromium alloy. 2. Slurry pump's bearing assembly use cylindrical structure, adjusting the space between impeller and front liner easily. They can be removed completely when being repaired. Bearing assembly use grease lubrication. 3. The shaft seal could use the packing seal, expeller seal and mechanical seal.

Details 1. The wet parts for slurry pump are made of wear-resistant high chromium alloy. 2. Slurry pump's bearing assembly use cylindrical structure, adjusting the space between impeller and front liner easily. They can be removed completely when being repaired. Bearing assembly use grease lubrication. 3. The shaft seal could use the packing seal, expeller seal and mechanical seal.  4. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. 5. There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices for the slurry pump. 6. Wide performance, good NPSH and high efficiency. The slurry pump can be installed in multistage series to meet the delivery for long distance.

4. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. 5. There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices for the slurry pump. 6. Wide performance, good NPSH and high efficiency. The slurry pump can be installed in multistage series to meet the delivery for long distance.  1). Cantilever, horizontal centrifugal slurry pump 2). Better wear-resistance and corrosive resistance 3). Frame plate for type pumps have replaceable wear-resistant metal ( high chrome alloy ) liners or rubber liners. Impeller material : high chrome alloy or Natural rubber . 4). In allowable pressure range, it can be used in series in stages, and allowable maximum working pressure is 3.6Mpa. 5). Expeller seal, mechanical seal and packing seal are available . 6). The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications. 7). To adapt to convey heavy abrasion, high concentration dreg , slurry pump's body is used double-deck construction , in other words, being made of inside lining and outside shell.

1). Cantilever, horizontal centrifugal slurry pump 2). Better wear-resistance and corrosive resistance 3). Frame plate for type pumps have replaceable wear-resistant metal ( high chrome alloy ) liners or rubber liners. Impeller material : high chrome alloy or Natural rubber . 4). In allowable pressure range, it can be used in series in stages, and allowable maximum working pressure is 3.6Mpa. 5). Expeller seal, mechanical seal and packing seal are available . 6). The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications. 7). To adapt to convey heavy abrasion, high concentration dreg , slurry pump's body is used double-deck construction , in other words, being made of inside lining and outside shell.

For example: 6/4E-NH 6:------------Suction diameter (inch) 4:------------Discharge diameter (inch) E:-----------Base type NH:---------Heavy abrasive slurry pump

For example: 6/4E-NH 6:------------Suction diameter (inch) 4:------------Discharge diameter (inch) E:-----------Base type NH:---------Heavy abrasive slurry pump

This Series of Pumps are used conveying abrasive or corrosive slurry, especially clinker of power plants in electric power, metallurgy, mining, coal, building materials, chemical industry and other industrial sectors,etc.

This Series of Pumps are used conveying abrasive or corrosive slurry, especially clinker of power plants in electric power, metallurgy, mining, coal, building materials, chemical industry and other industrial sectors,etc.

Shijiazhuang Nainater Slurry Pump Co., Ltd (NNT Pump) Website: http://www.nntpump.com Address: No.1, Tianshan Street, Hi-tech Zone, Shijiazhuang City, Hebei Province, China If you have any questions ,please feel free to contact with me via Trade Manager , Skype or Email . We will reply within 12 hours .

Shijiazhuang Nainater Slurry Pump Co., Ltd (NNT Pump) Website: http://www.nntpump.com Address: No.1, Tianshan Street, Hi-tech Zone, Shijiazhuang City, Hebei Province, China If you have any questions ,please feel free to contact with me via Trade Manager , Skype or Email . We will reply within 12 hours .

Send your inquiry to this supplier

Send Inquiry