Video

1 / 4

SKJ350 wood pellet making machines

$5500.00

≥1 Set/Sets

Jinan, Shandong, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

PRODUCT INTRODUCTION

Biomass pelletizer is a biomass energy pretreatment equipment. It mainly uses agricultural and forestry processing wastes such as sawdust, straw, rice husk, bark and other biomass as raw materials. Through pretreatment and processing, it is solidified into high-density pellet fuel. Biomass pellet machine is divided into flat die biomass pellet machine and ring die biomass pellet machine. Biomass fuel is the use of crops of corn stalks, wheat straw, straw, peanut shells, corn cobs, cotton stalks, soybean stalks, husks, weeds, branches, leaves, sawdust, bark and other solid waste as raw materials, through crushing, pressurizing, densification, molding, become small rod-like solid pellet fuel. Pellet fuel is made by extrusion of sawdust, straw and other raw materials with pressure roller and ring die at room temperature. The density of raw materials is generally about 0.6-0.8, and the particle density after molding is greater than 1.1, which is very convenient for transportation and storage. At the same time, its combustion performance is greatly improved, which brings certain employment problems and economic benefits.

PRICIPLE OF OPERRATION

Based on the inherent motion of the machine, the equipment is powered by the motor ( or diesel engine ), which drives the gear to the main shaft. Under the action of the friction force, the pressure roller rotates, so that the corresponding friction temperature is generated between the pressure roller and the die, so that the powder material is plasticized, the proteolipid is subjected to temperature denaturation, and is extruded from the die hole under the extrusion of the pressure wheel. The required particle length can be obtained by adjusting the cutter, and then the particles are sent out of the machine through the discharge port through the throwing plate.

PRODUCT ADVANTAGES

1.High combustion thermal efficiency, biomass pellet fuel can greatly improve the combustion performance of wood materials, thermal efficiency can be increased by more than 80 %, 1 ton of biomass pellet fuel generated heat equivalent to 0.8 tons of coal.

2.Safety of use, biomass pellet fuel due to take from the natural state of sawdust, wood, straw, wood, wood scraps, and other wood raw materials, does not contain fissile, explosive and other chemical substances, it will not occur poisoning, explosion, leakage and other accidents.

3.clean and environmentally friendly, biomass pellet fuel is a natural biomass pellet fuel, can replace coal and natural gas.

4.Space saving. Biomass fuels are compressed at high temperatures, which greatly saves storage space and facilitates transportation.

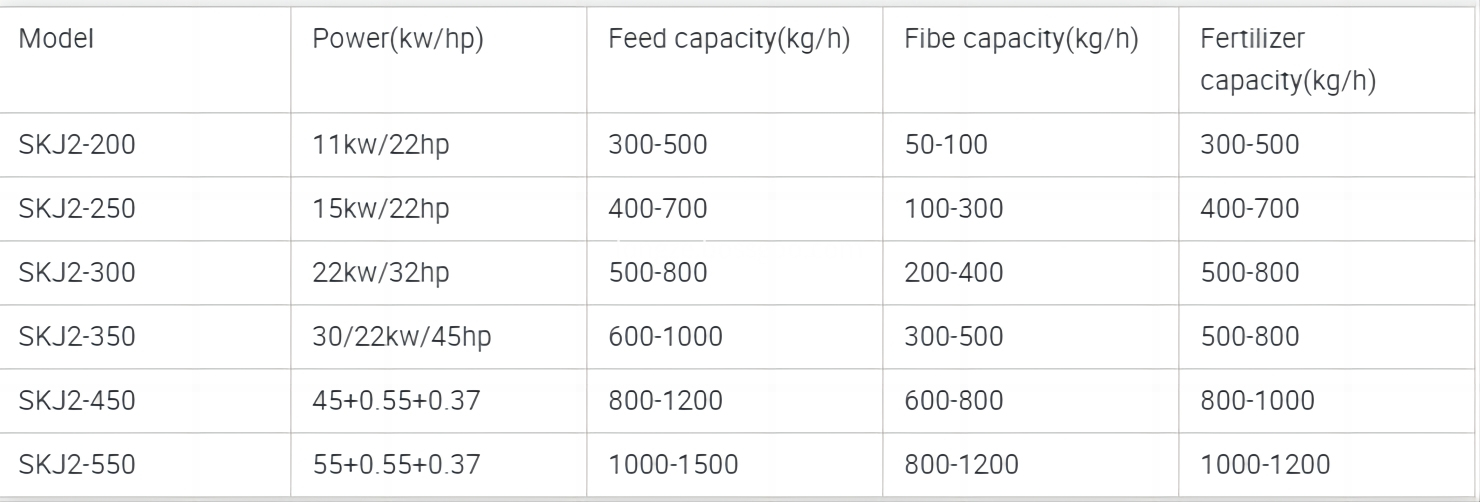

TECHNICAL PARAMETER

CONTACT US

Video

Jinan, Shandong, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier