1 / 1

shanghai plastic electrical appliance mould

| Model No. : | plastic electrical appliance mould |

|---|---|

| Brand Name : | SPM |

Product description

2.ISO9001:2008 certified

3.shanghai plastic electrical appliance mould

4.Great team work

Firstly,look at some products we ever made

Product name: | shanghai plastic electrical appliance mould |

The company's strengths: | 1,Efficient team 2,Delivery in time 3,Excellent equipment 4,High quality and competitive price |

Core and Cavity Material: | 718,718H,S136,NAK80,P20,SKD61,etc. |

Plastic Material: | ABS,PP,PE,PET,EVA,PMMA,PC,PU,etc. |

Main Processing Equipment | CNC,Wire cutting, Grinding machine,Lathe,Drill Press,EDM center Injection machine,etc. |

Practicable Software: | Pro/engineer,Solidworks,UG,Auto cad. |

Business Scope: | 1,Industrial design 2,Mould making 3,Parts machining 4,Injection molding 5,CNC prototype manufacturing |

Advantage & Benefits you expect here:

Advantage & Benefits you expect here: |

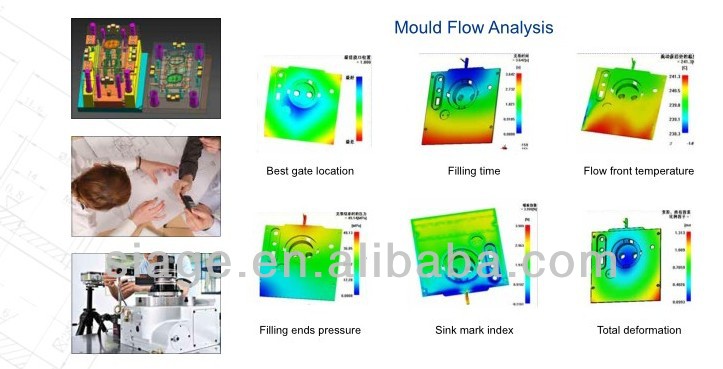

R&D alibility | My team can work on both product&mould design, software using here: UG/PRoE/Solidworks/Autocad,etc.Right now we already had 3 patents from my state.

|

|

Quality&Precision | 1. We utilize ISO9001:2008 & TS16949 standards in our operation 2. CNC tolerance: +/-0.005mm 3. WC tolerance:+/-0.003mm 4. EDM Mirror tolerance:+/-0.003mm 5. Precise Grinding Machine:+/-0.001mm 6.Main market:Japan,Europe,North America,you can expect the highest standard at most reasonable costs.

|

|

Professional Team | 1.my team have strong capability to support you from an idea or sample -design-production-surface treatment-assembly-packing-shipping,etc.

2.we have separate machining&mold making&injection&assembly workshops to meet your various requirements.

3.good knowledge to solve problems, be responsive.

4.Turnkey Project: We have one team with supervisory personnel to check the quality of product before and after producing line. |

|

After-sales Services |

Experienced engineers will provide all-round technical solutions to any problems occurred in customers mould operation.

Our belief: company's sustainable development means customer benefits,win-win situation-as we have been and will always deliver our products beyond customer expectation. |

Best Plastic Injection Moulding Best Plastic Injection for Household in China Plastic Injection Moulding Machine Plastic Mold,Mold Maker Mold /Mould Maker for Plastic Product, OEM Mould for Product, Plastic Mold for Plastic Products injection mould/Mold, Injection Moulding for Injection Moulding Machine Product for Plastic Products

Best Plastic Injection Moulding Best Plastic Injection for Household in China Plastic Injection Moulding Machine Plastic Mold,Mold Maker Mold /Mould Maker for Plastic Product, OEM Mould for Product, Plastic Mold for Plastic Products injection mould/Mold, Injection Moulding for Injection Moulding Machine Product for Plastic Products

QC (inspection everywhere ): - Firstly, check the raw material before massive production; - During production, technicians self-check and Engineer spot check to assure the good quality. -QC inspect after products finished - Before package, we will choose the best way to avoid damages during transportation. - Salesmen who were trained the technical know-how spot check before shipping. Right now we're working with over 30 countries,below are some pics taken during their visiting,thanks!

QC (inspection everywhere ): - Firstly, check the raw material before massive production; - During production, technicians self-check and Engineer spot check to assure the good quality. -QC inspect after products finished - Before package, we will choose the best way to avoid damages during transportation. - Salesmen who were trained the technical know-how spot check before shipping. Right now we're working with over 30 countries,below are some pics taken during their visiting,thanks!  FAQ: 1.What do you need for a quotation? Our company is specialized in plastic moulds and,extrusion moulding and plastic injection products. You need to send us 2D or 3D drawings or samples.Then we can quote exactly as your requirement. 2.For the runner ,what is available? According to customer’s requirement .we can use the hot or cold runner. 3.What material are used for the mould? We usually use the mould steel such as:S45C,S50C,P20,S136H,718,718H,2738,2316,2083,2311,NAK80,H13,etc. 4.What software is used in your company for mould design,product design,CNC programming? For mould design ,we use UG,Proe,AutoCAD,Solidworks,etc. For CNC programming ,we use powermill. 5.How long it is for the lead time of the first mold test ? Usually the lead time for the first mould test is 35days.The difference is based on the size and structure of the mould Any Enquiry contact me now,thanks! Tel:+86-21-57677097 Skype:spm.cora Mob:+86-18701728067

FAQ: 1.What do you need for a quotation? Our company is specialized in plastic moulds and,extrusion moulding and plastic injection products. You need to send us 2D or 3D drawings or samples.Then we can quote exactly as your requirement. 2.For the runner ,what is available? According to customer’s requirement .we can use the hot or cold runner. 3.What material are used for the mould? We usually use the mould steel such as:S45C,S50C,P20,S136H,718,718H,2738,2316,2083,2311,NAK80,H13,etc. 4.What software is used in your company for mould design,product design,CNC programming? For mould design ,we use UG,Proe,AutoCAD,Solidworks,etc. For CNC programming ,we use powermill. 5.How long it is for the lead time of the first mold test ? Usually the lead time for the first mould test is 35days.The difference is based on the size and structure of the mould Any Enquiry contact me now,thanks! Tel:+86-21-57677097 Skype:spm.cora Mob:+86-18701728067 Send your inquiry to this supplier