1 / 4

saw dust dryer rotary drum dryer

Get Latest Price

Send Inquiry

| Model No. : | TN-ORIENT |

|---|---|

| Brand Name : | TN-ORIENT |

Xuzhou Orient Industry Co., Ltd.

You might also like

Product description

Product Detail WSG-Series saw dust dryer rotary drum dryer can be used to dry the following material: a. Sawdust, grazing, leaves, sugarcane biogases, and animals’ wastes and so on. And it can be used in Chemical Plant, Mine, Metallurgy and other industries. For example, the ore, the scoria, coal, metallic powder, phosphor fertilizer, sulfur.

b. It can dry the granule materials which have special requesting and must dry in low temperature. For example, Vesicant; Lightweight Calcium Carbonate; Active Dust; Magnet Powder; Plumbago and so on.

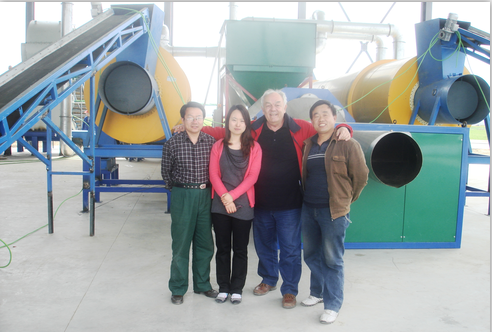

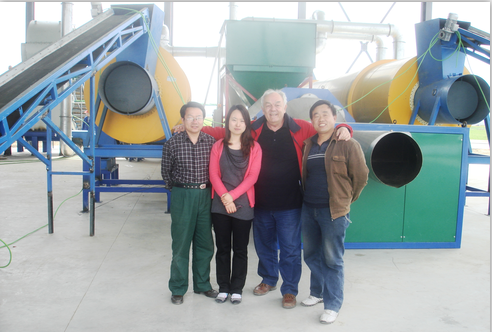

Detailed Images

Packing and Delivery Packing and Delivery - Base on the shape and weight of machine to choose the wood pallet or iron pallet. 100% well-packing to ensure the arrival safety with ocean cargo insurance. - We send our packer to the port to inspect the loading.

Packing and Delivery Packing and Delivery - Base on the shape and weight of machine to choose the wood pallet or iron pallet. 100% well-packing to ensure the arrival safety with ocean cargo insurance. - We send our packer to the port to inspect the loading.

Our Company - Established in 1997, exported the first set of Wood Pellet Machine to Korea in 2000; 16 years experience in the biomass pelletizing field. - Adwarded High-Tech Enterprise of Shandong Province. -Covering > 170,000 square meters (260 acres), and has 97,000 square meters modern production workshop. - Hold over 25 national unique patents - Certificated by CE, ISO9001, SGS - 60% market share in the domestics; exported over 50 countries. - Specialized in the turn-key project in the biomass pelletizing field from Debarking - Chipping - Crushing - Drying - Pelletizing - Cooling and Sieve - Packing - Dedusting - Heating Supplying.

Our Company - Established in 1997, exported the first set of Wood Pellet Machine to Korea in 2000; 16 years experience in the biomass pelletizing field. - Adwarded High-Tech Enterprise of Shandong Province. -Covering > 170,000 square meters (260 acres), and has 97,000 square meters modern production workshop. - Hold over 25 national unique patents - Certificated by CE, ISO9001, SGS - 60% market share in the domestics; exported over 50 countries. - Specialized in the turn-key project in the biomass pelletizing field from Debarking - Chipping - Crushing - Drying - Pelletizing - Cooling and Sieve - Packing - Dedusting - Heating Supplying.

- Branches Companies as following: Jining Tiannong Machine Co., Ltd. Jining Naijiu Mould Co., Ltd

Xuzhou Orient Industry Co., Ltd.

Weishan Hengjie Furnace Technology Co.

Weishan Tianong Science and Technology Co.

TeYiAn Robot Science and Technology Co.

ToPellet Machinery GmbH

Related products Our company also have Ring die pellet mill,Flat die pellet mill, Hammer mill, Briquetting machine, pellet packing machine,pellet stove, pellet burner, ect,

Related products Our company also have Ring die pellet mill,Flat die pellet mill, Hammer mill, Briquetting machine, pellet packing machine,pellet stove, pellet burner, ect,

pellet mill hammer mill pellet burner

pellet mill hammer mill pellet burner

Biomass gasifier

Biomass gasifier

Biomass briquetting machine

pellet line

Certification Our Service

Our Service

Customer is God. Your satisfaction is our unremitting pursue.

FAQ Preparation for Pelletizing The raw material should be 3-6mm detritus with moisture 14-16%. Which process is better? Chipping - Crushing - Drying is better than the process of Chipping - Drying - Crushing - Drying. The big material is difficult to dry which will need more heating energy. Our Crusher can crush the wet material efficiently. The effection on moisture and size to Crusher The wet material is more difficult to crush than the material with moisture less 20%. When you require the Crusher to hammer the material into smaller pieces, it will decrease the output and increase the eletrical consumption. How to choose Dryer? Three-pass Dryer is not suitable to dry the saw dust or wood chip, it will need more heating energy and electrical consumption. And the structure of Three-pass Dryer is difficult to maintain. How to choose Pellet Machine Quality is the most important element. The second is to analysis the cost to product pellet from the machine on Electrical Consumption, Lubricating Oil, Life of Wearing Spare Parts. The safety device on machine is also important. Non-dust workshop is impossible or not? Non-dust workshop is possible, but you will need to cost the money which is equal to buy 1 complete pellet plant from China to realize it.

FAQ Preparation for Pelletizing The raw material should be 3-6mm detritus with moisture 14-16%. Which process is better? Chipping - Crushing - Drying is better than the process of Chipping - Drying - Crushing - Drying. The big material is difficult to dry which will need more heating energy. Our Crusher can crush the wet material efficiently. The effection on moisture and size to Crusher The wet material is more difficult to crush than the material with moisture less 20%. When you require the Crusher to hammer the material into smaller pieces, it will decrease the output and increase the eletrical consumption. How to choose Dryer? Three-pass Dryer is not suitable to dry the saw dust or wood chip, it will need more heating energy and electrical consumption. And the structure of Three-pass Dryer is difficult to maintain. How to choose Pellet Machine Quality is the most important element. The second is to analysis the cost to product pellet from the machine on Electrical Consumption, Lubricating Oil, Life of Wearing Spare Parts. The safety device on machine is also important. Non-dust workshop is impossible or not? Non-dust workshop is possible, but you will need to cost the money which is equal to buy 1 complete pellet plant from China to realize it.

b. It can dry the granule materials which have special requesting and must dry in low temperature. For example, Vesicant; Lightweight Calcium Carbonate; Active Dust; Magnet Powder; Plumbago and so on.

Packing and Delivery Packing and Delivery - Base on the shape and weight of machine to choose the wood pallet or iron pallet. 100% well-packing to ensure the arrival safety with ocean cargo insurance. - We send our packer to the port to inspect the loading.

Packing and Delivery Packing and Delivery - Base on the shape and weight of machine to choose the wood pallet or iron pallet. 100% well-packing to ensure the arrival safety with ocean cargo insurance. - We send our packer to the port to inspect the loading.

Our Company - Established in 1997, exported the first set of Wood Pellet Machine to Korea in 2000; 16 years experience in the biomass pelletizing field. - Adwarded High-Tech Enterprise of Shandong Province. -Covering > 170,000 square meters (260 acres), and has 97,000 square meters modern production workshop. - Hold over 25 national unique patents - Certificated by CE, ISO9001, SGS - 60% market share in the domestics; exported over 50 countries. - Specialized in the turn-key project in the biomass pelletizing field from Debarking - Chipping - Crushing - Drying - Pelletizing - Cooling and Sieve - Packing - Dedusting - Heating Supplying.

Our Company - Established in 1997, exported the first set of Wood Pellet Machine to Korea in 2000; 16 years experience in the biomass pelletizing field. - Adwarded High-Tech Enterprise of Shandong Province. -Covering > 170,000 square meters (260 acres), and has 97,000 square meters modern production workshop. - Hold over 25 national unique patents - Certificated by CE, ISO9001, SGS - 60% market share in the domestics; exported over 50 countries. - Specialized in the turn-key project in the biomass pelletizing field from Debarking - Chipping - Crushing - Drying - Pelletizing - Cooling and Sieve - Packing - Dedusting - Heating Supplying. - Branches Companies as following: Jining Tiannong Machine Co., Ltd. Jining Naijiu Mould Co., Ltd

Xuzhou Orient Industry Co., Ltd.

Weishan Hengjie Furnace Technology Co.

Weishan Tianong Science and Technology Co.

TeYiAn Robot Science and Technology Co.

ToPellet Machinery GmbH

Related products Our company also have Ring die pellet mill,Flat die pellet mill, Hammer mill, Briquetting machine, pellet packing machine,pellet stove, pellet burner, ect,

Related products Our company also have Ring die pellet mill,Flat die pellet mill, Hammer mill, Briquetting machine, pellet packing machine,pellet stove, pellet burner, ect,

pellet mill hammer mill pellet burner

pellet mill hammer mill pellet burner

Biomass gasifier

Biomass gasifier Biomass briquetting machine

pellet line

Certification

Our Service

Our Service Customer is God. Your satisfaction is our unremitting pursue.

FAQ Preparation for Pelletizing The raw material should be 3-6mm detritus with moisture 14-16%. Which process is better? Chipping - Crushing - Drying is better than the process of Chipping - Drying - Crushing - Drying. The big material is difficult to dry which will need more heating energy. Our Crusher can crush the wet material efficiently. The effection on moisture and size to Crusher The wet material is more difficult to crush than the material with moisture less 20%. When you require the Crusher to hammer the material into smaller pieces, it will decrease the output and increase the eletrical consumption. How to choose Dryer? Three-pass Dryer is not suitable to dry the saw dust or wood chip, it will need more heating energy and electrical consumption. And the structure of Three-pass Dryer is difficult to maintain. How to choose Pellet Machine Quality is the most important element. The second is to analysis the cost to product pellet from the machine on Electrical Consumption, Lubricating Oil, Life of Wearing Spare Parts. The safety device on machine is also important. Non-dust workshop is impossible or not? Non-dust workshop is possible, but you will need to cost the money which is equal to buy 1 complete pellet plant from China to realize it.

FAQ Preparation for Pelletizing The raw material should be 3-6mm detritus with moisture 14-16%. Which process is better? Chipping - Crushing - Drying is better than the process of Chipping - Drying - Crushing - Drying. The big material is difficult to dry which will need more heating energy. Our Crusher can crush the wet material efficiently. The effection on moisture and size to Crusher The wet material is more difficult to crush than the material with moisture less 20%. When you require the Crusher to hammer the material into smaller pieces, it will decrease the output and increase the eletrical consumption. How to choose Dryer? Three-pass Dryer is not suitable to dry the saw dust or wood chip, it will need more heating energy and electrical consumption. And the structure of Three-pass Dryer is difficult to maintain. How to choose Pellet Machine Quality is the most important element. The second is to analysis the cost to product pellet from the machine on Electrical Consumption, Lubricating Oil, Life of Wearing Spare Parts. The safety device on machine is also important. Non-dust workshop is impossible or not? Non-dust workshop is possible, but you will need to cost the money which is equal to buy 1 complete pellet plant from China to realize it. Send your inquiry to this supplier

Send Inquiry