1 / 1

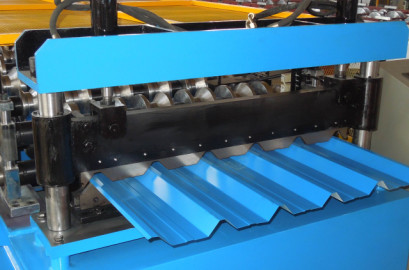

Roof/Wall Roll Forming Machine (YX35-125-750/875)

Get Latest Price

Send Inquiry

| Model No. : | (YX35-125-750/875) |

|---|

Wuxi Yajie Roll Forming Machinery Co., Ltd.

You might also like

Product description

Product Description

Machine components:

Roll forming machine consists of uncoiler, coil sheet guiding device, main roll forming system, cutting device, Hydraulic station, PLC control system and support table.

Main technical parameters:

1. Suitable material: Color steel sheet or galvanized steel sheet

2. Thickness of raw material: 0.4-0.7mm

3. Yield strength of material: 235Mpa-345Mpa

4. Forming speed: About 20m/min

5. Power Requirement: Main motor power: 5.5Kw (Depend on final design)

Hydraulic station power: 2.2Kw (Depend on final design)

6. Uncoilers loading capacity Max. Capacity: 5000kgs (can be increased to be 10T)

7. Controlling system: Mitsubishi PLC & Converter

8. Machines weight: About 9-14T for different profile machine

9. Installation size: About 18m× 1.8m× 1.4m (Depend on final design)

Material of Main Equipment

Roller Material: High grade No. 45 forged steel, with digital-controlled procession, Plated with hard chrome.

Active Shaft Material: High grade No. 45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. Shaft diameter is 72mm.

Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements from famous suppliers in China

Cutter blade: Cr12 mould steel with quenched treatment

Machine With CE Certificate

Customers' specification can be design here.

About us

We supply roll forming machines with good quality, low prices and good service after sales, such as roof & wll panel forming machine, purlin forming machine, floor deck forming machine, etc, so if you are interested, please feel free to contact us.

Roll forming machine consists of uncoiler, coil sheet guiding device, main roll forming system, cutting device, Hydraulic station, PLC control system and support table.

Main technical parameters:

1. Suitable material: Color steel sheet or galvanized steel sheet

2. Thickness of raw material: 0.4-0.7mm

3. Yield strength of material: 235Mpa-345Mpa

4. Forming speed: About 20m/min

5. Power Requirement: Main motor power: 5.5Kw (Depend on final design)

Hydraulic station power: 2.2Kw (Depend on final design)

6. Uncoilers loading capacity Max. Capacity: 5000kgs (can be increased to be 10T)

7. Controlling system: Mitsubishi PLC & Converter

8. Machines weight: About 9-14T for different profile machine

9. Installation size: About 18m× 1.8m× 1.4m (Depend on final design)

Material of Main Equipment

Roller Material: High grade No. 45 forged steel, with digital-controlled procession, Plated with hard chrome.

Active Shaft Material: High grade No. 45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. Shaft diameter is 72mm.

Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements from famous suppliers in China

Cutter blade: Cr12 mould steel with quenched treatment

Machine With CE Certificate

Customers' specification can be design here.

About us

We supply roll forming machines with good quality, low prices and good service after sales, such as roof & wll panel forming machine, purlin forming machine, floor deck forming machine, etc, so if you are interested, please feel free to contact us.

| Technical parameter | ||

| Item | Specification | |

|

Raw Material |

Type | Pre-painted steel coil |

| Thickness(mm) | 0.4-0.6 | |

| Yield strength(mpa) | 235-345 | |

| Roller material | 45# steel , coated with Chrome | |

| Shaft for rollers | Solid shaft with 72mm,processed with cylindrical grinder | |

| Forming speed(m/min) | About 15-20 | |

| Output speed(m/min) | 3-4 | |

| Speed adjusting mode | Mitsubishi frequency transformer | |

| Roller drive | Decelerating motor + Chain drive | |

| Cutting mode | Hydraulic cutting | |

| Cutter material | Cr12 mould steel | |

| Length measurement | Nemicon Encoder | |

| Control mode | Mitsubishi PLC | |

| Operating mode | Button + Mitsubishi Touch screen | |

| Main motor power(kw) | 5.5KW | |

| Total power(kw) | 11KW | |

| Process flow | Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic pressing ---Hydraulic Cutting – product to run out table | |

| Components of machine | ||

| Decoiler (manual decoiler and hydraulic decoiler for option) | 1set | |

| Feeding & guiding device | 1set | |

| Main roll forming machine | 1set | |

| Hydraulic pressing system | 1set | |

| Hydraulic cutting system | 1set | |

| Controlling system | 1set | |

| Run out table | 1set | |

Send your inquiry to this supplier

Send Inquiry