1 / 2

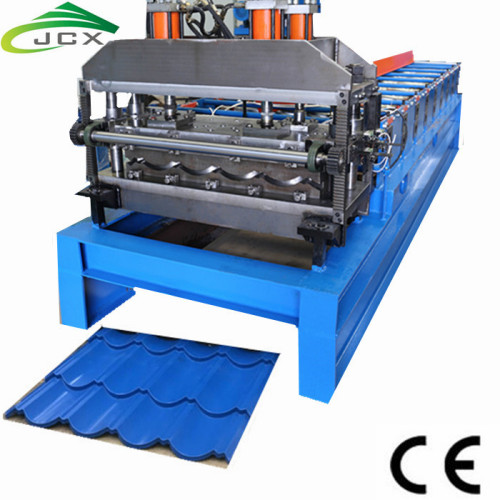

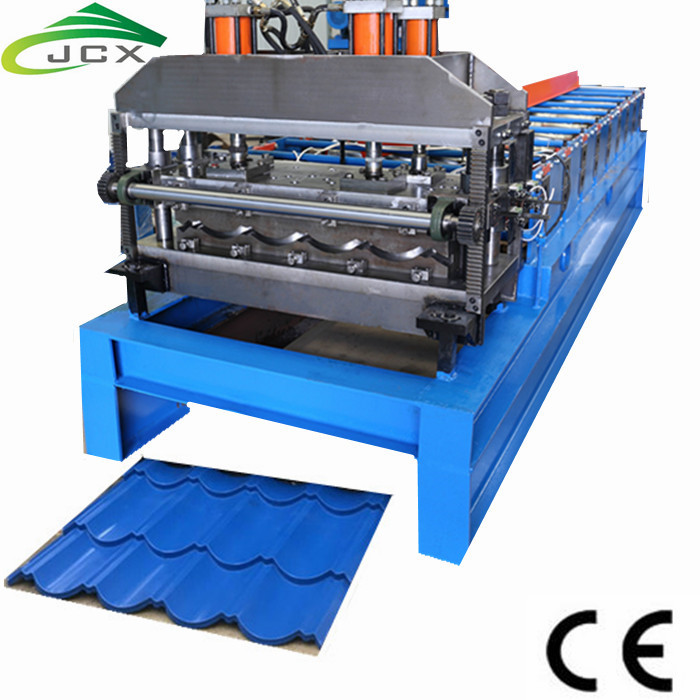

Roof Sheet Forming Machine Price For Africa

| Model No. : | 828 |

|---|---|

| Certification : | CE |

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

Roof Sheet Forming Machine Price For Africa

There is only one but key difference between a metal glazed roof tile and a regular metal roof panel: Steps! Generally speaking, a regular metal roof panel with steps is called a metal glazed roof tile! Metal step tile are widely used in resisdential house.Now more people use metal sheet to replace brick roof.This step tile used a lot in Nigeria,and they use aluminum as raw material.It is light and anti rust.

Therefore the key difference between a regular metal roof sheet forming machine for africa and a metal glazed tile roll forming machine lies at this situation that there is an extra hydraulic pressing equipment on a step tile roll forming machine to press steps on the roll formed roof panels.

Our Steel Sheet Roof Forming Machine can be used a workshop.

Parameters of raw material

| Material | Thickness | I.D | Yield Strength |

|

Q235 gi&ppgi& galvalume |

0.25-0.7mm | 508mm | <=235mpa |

2.Photos of Machine:

The weight of machine is about3.1tons.The total dimension of machine:6800(L)*1200(W)*1500mm(H)

3.1Manual decoiler:

Capacity of uncoiler:5tons

Expansion of segment:Manual

Rotation of segment:Manual

Number of segment:4

Range of segment expansion:480-520mm

Operation method:Manual

Qty: 1

3.2 Guiding system:

To keep the material straight

Entrance and adjustable wheel: 2rolls

Qty: 1

3.3Main forming machine:

Coil thickness:0.25-0.7mm

motor type: 3 phase asynchronous motor

Main motor power:4kw+3kw(normal speed),

Approx.18groups roller including

Roller : S45C with quenching treatment,Shafts of rollers are tooled by grinding machine for two times to ensure the precision of final product.

Shaft:Diameter of max shaft: ø70mm(hardening and tempering)

Transmission type:by one inch chain

Qty: 13.4 Hydraulic cutting:

Material of blade: Cr12Mov,HRC58-62

Length measuring: Automatic encoder length measuring

Type of cutting:Cutting after forming:Cut the sheet after roll forming to required length.No need to change mold for different sizes

Cutting motion:The main machine automatically stops and the cutting will take place.After the cutting,the main machine will automatically start.

Power of motor:3kw

3.5 Product support frame

Size: L 3m x W0.5m

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier