1 / 1

river dredging sand and gravel pumps

Get Latest Price

Send Inquiry

| Model No. : | AMG river dredging sand and gravel pumps |

|---|---|

| Brand Name : | An Pump |

Shijiazhuang An Pump Machinery Co., Ltd.

You might also like

Product description

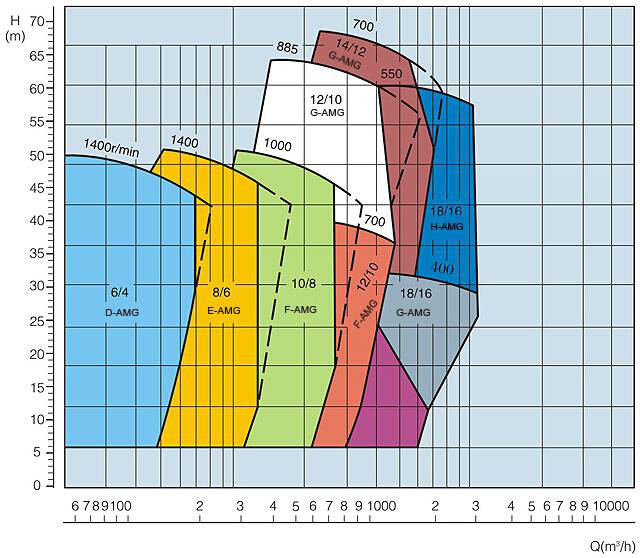

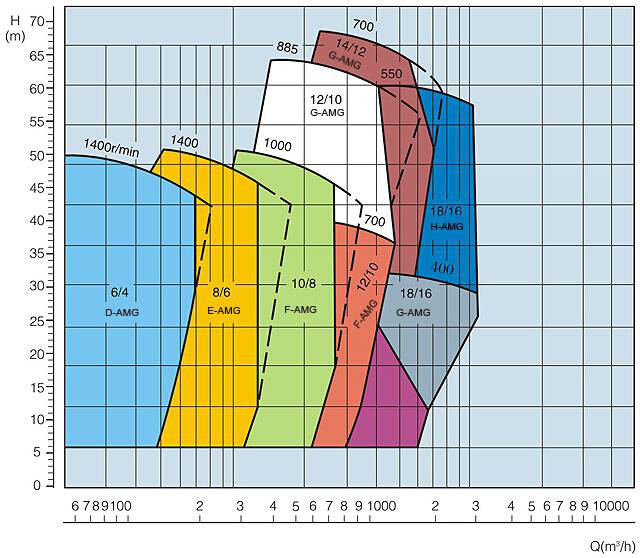

river dredging sand and gravel pumps Pump Application >>Sand gravel pump application  Product Description >>Centrifugal Sand gravel pump Performance Data

Product Description >>Centrifugal Sand gravel pump Performance Data

>>Sand gravel pump information AMG/AMGH gravel pumps, Construction of this pump is of single casing connected by means of clamp bands and wide wet passage. The wet parts are made of Ni hard and high chromium abrasion resistance alloys. The discharge direction of pump can be oriented in any direction of 360 degrees. This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance.  Drive types includes V-belts driven, flexible coupling driven, gear box driven, hydraulic coupler driven, variable frequency driven, thyristor speed control etc. AMG/AMGH gravel pump are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type GH pumps are of high head ones

Drive types includes V-belts driven, flexible coupling driven, gear box driven, hydraulic coupler driven, variable frequency driven, thyristor speed control etc. AMG/AMGH gravel pump are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type GH pumps are of high head ones  Introduction-- Coal Washing Sand Pump 1) The gravel pumps are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in Mining, Explosive sludge in metal melting, Dredging in dredger and course of rivers, and other fields. Type SHG pumps are of high-head ones.

Introduction-- Coal Washing Sand Pump 1) The gravel pumps are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in Mining, Explosive sludge in metal melting, Dredging in dredger and course of rivers, and other fields. Type SHG pumps are of high-head ones.

2) Construction of this pump is of single casing connected by means of clamp bands and wide wet-passage. The wet -parts are made of Ni-hard and high chromium abrasion-resistance alloys. The discharge direction of pump can be oriented in any direction of 360 degree. 3) This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance. Packaging & Shipping >>Standard wooden case packing  Our Services >>An Pump Machinery Company to Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock. Contact us

Our Services >>An Pump Machinery Company to Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock. Contact us  We’d Love to Hear From You, Get In Touch With Us!

We’d Love to Hear From You, Get In Touch With Us!

Product Description >>Centrifugal Sand gravel pump Performance Data

Product Description >>Centrifugal Sand gravel pump Performance Data Model | Outlet Dia (mm) | Speed (rpm) | Flow (m3/h) | Head (m) | Max Power (kw) | Max Solid (mm) |

6/4D-AMG | 100 | 600-1400 | 36-250 | 7-56 | 60 | 82 |

8/6E-AMG | 150 | 800-1400 | 180-540 | 12-52 | 120 | 120 |

10/8F-AMG | 200 | 500-1000 | 180-820 | 12-56 | 560 | 178 |

12/10G-AMG | 250 | 400-850 | 360-1200 | 12-60 | 600 | 220 |

14/12G-AMG | 300 | 300-700 | 700-2700 | 8-70 | 600 | 241 |

14/12TU-AMG | 300 | 300-700 | 700-2700 | 8-70 | 1200 | 241 |

10/8F-AMGH | 200 | 500-1100 | 50-900 | 20-90 | 560 | 180 |

12/10G-AMGH | 250 | 350-700 | 500-2000 | 20-80 | 600 | 210 |

16/14TU-AMGH | 350 | 250-500 | 1000-2800 | 20-80 | 1200 | 230 |

Drive types includes V-belts driven, flexible coupling driven, gear box driven, hydraulic coupler driven, variable frequency driven, thyristor speed control etc. AMG/AMGH gravel pump are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type GH pumps are of high head ones

Drive types includes V-belts driven, flexible coupling driven, gear box driven, hydraulic coupler driven, variable frequency driven, thyristor speed control etc. AMG/AMGH gravel pump are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in mining, explosive sludge in metal melting, grudging in dredger and course of river, and other fields. Type GH pumps are of high head ones  Introduction-- Coal Washing Sand Pump 1) The gravel pumps are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in Mining, Explosive sludge in metal melting, Dredging in dredger and course of rivers, and other fields. Type SHG pumps are of high-head ones.

Introduction-- Coal Washing Sand Pump 1) The gravel pumps are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in Mining, Explosive sludge in metal melting, Dredging in dredger and course of rivers, and other fields. Type SHG pumps are of high-head ones.

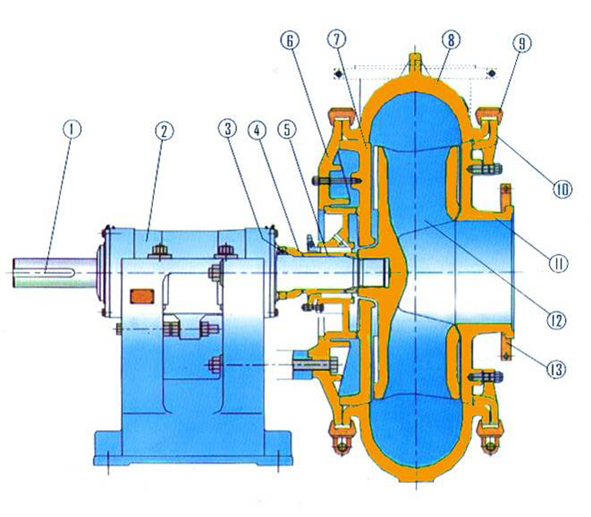

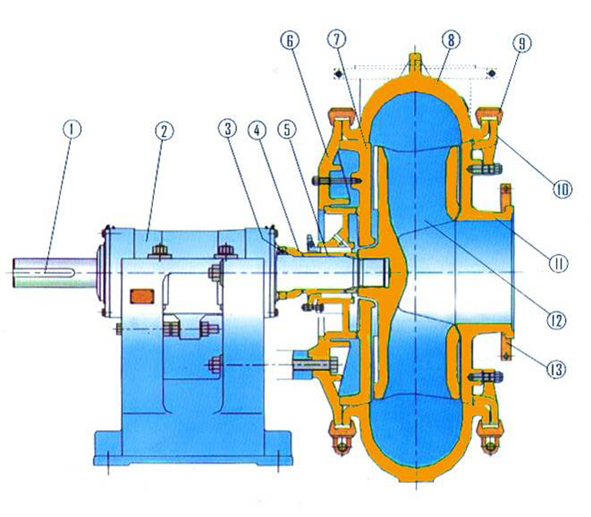

1.Shaft | 2.Frame plate | 3.Impeller stripping ring | 4.Shaft spacer | 5.Sealing assembly | ||

6.Bowl | 7.Frame plate liner insert | 8. Pump casing | 9.Adapter plate clamp ring | 10.Pump cover | ||

11.Throat bush | 12.Impeller | 13.Flange | ||||

Our Services >>An Pump Machinery Company to Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock. Contact us

Our Services >>An Pump Machinery Company to Customers: 1)Quality first. We guaranteed every part of the pump must be inspected closely 2)We can help you select suitable pump model according to your working condition and requirements. 3)We can design the related base or engine for your pumps. 4)Fast delivery time, large quantity of spare parts in stock. Contact us  We’d Love to Hear From You, Get In Touch With Us!

We’d Love to Hear From You, Get In Touch With Us! Send your inquiry to this supplier

Send Inquiry