1 / 1

Quality High Purity Medical Oxygen Gas Plant

| Brand Name : | Doer |

|---|---|

| Old and new : | New |

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Product description

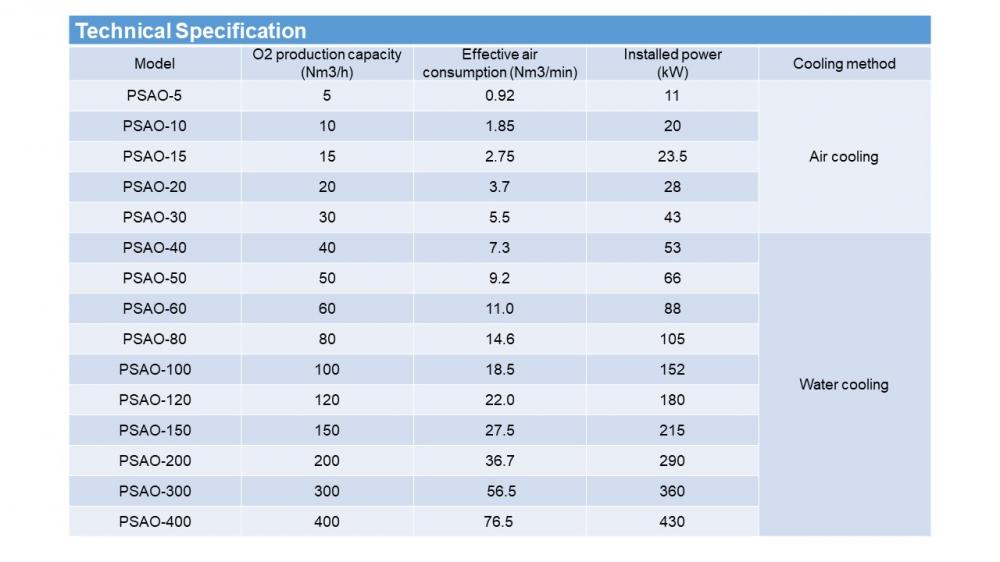

O2 flow rate: 30 Nm3/h (customizable).

O2 purity: 95±2% (vol) (customizable).

O2 dew point: ≤-50℃.

Outlet pressure: 15 Mpa.

Air consumption rate: 5.5 Nm3/min.

Installed power: 43 kW.

Cooling method: air cooling.

TECHNICAL SPECIFICATION

(Cryogenic Storage tanks, Large Scale Flat Bottom Cryogenic Liquid Storage tanks, PSA Oxygen Plant, VPSA Oxygen Plant, Cryogenic Air Separation Units, Air Heated Vaporizers, Water Bath Vaporizers)

PROCESS FLOW CHART

Air compression system->Air purification system->Air buffer tank->Air adsorbtion & separation system->Air buffer & despensing system.

Pressure swing adsorption (PSA) is a technique used to separate some gas species from a mixture of gases (typically air) under pressure according to the species' molecular characteristics and affinity for an adsorbent material. It operates at near-ambient temperature and significantly differs from the cryogenic distillation commonly used to separate gases. Selective adsorbent materials (e.g., zeolites, (aka molecular sieves), activated carbon, etc.) are used as trapping material, preferentially adsorbing the target gas species at high pressure. The process then swings to low pressure to desorb the adsorbed gas.

PAST PROJECTS

①PSAO-200 for Myanmar glass plant.

②PSAO-250 for China sewage treatment project.

③PSAO-150 for Kazakhstan fish farming.

④PSAO-350 for Pakistan copper smeltery project.

⑤PSAO-100 for China welding plant.

TECHNICAL FEATURES

•Low energy consumption, stable performance, integrated skid structure, easy erection, reduced floor space;

•Simple operation, intelligent control, high degree of automation, fast production, highly flexible control;

•Unique honeycomb constant flow diffusion technique to ensure the adsorption rate of molecular sieve;

•Special protective holddown device to ensure a long lifetime of zeolite molecular sieve;

•Control valves and other components of well-known brands;

•Automatic blowback of unqualified oxygen to guarantee output purity and save energy;

•Multiply fault detection, alarming and troubleshooting functions;

•Optional HMI, energy-saving control, dew point control, DCS communication etc.

WHY US

• Professional & experienced teams.

State-of-art technologies, focusing on innovation & staff training.

Over 12 years in the industry, one of the most fast-growing.

• One-stop solution.

Integrated service of design, manufacture, delivery, erection, commissioning & more.

A wide range of products, accessories inclusive, four manufacturing bases across China.

• Preeminent product quality.

Certified by multiple international authorities/organizations.

High operational stability with top quality components.

• Customer oriented.

Custom made solutions for practical difficulties.

Cost-effective, win-win business development.

APPLICATIONS

Agricultural products manufacturing, Aircraft & aerospace applications, Chemical processing, Cosmetics processing, Cutting & welding, Environmental protection, Food and beverage processing, Glass, ceramics, other minerals, Medical gas therapy, Metallurgy, Mining operations, Oil and fuel processing, Plastic processing, Pharmaceutical processing, Power generation, Pulp and paper processing, Rubber, plastics, paint, Underwater diving, Water treatment / industrial water treatment, Etc.

INTEGRATED SERVICE

Inquiry->Solution->Agreement->Payment->Production->Delivery->Installation->Service

ABOUT US

China Doer Gas & Chemical Equipment Co., Ltd. Is one of the fastest growing corporation in the industry since its foundation in 2009 thanks to its advantages in excellent quality, technological innovation and heartfelt service. It now has set up four manufacturing bases across China, obtained over 60 patents and multiple international certificates, and is reaching out for more and more global customers with a wide range of products, standard or custom-made, covering cryogenic storage tanks, vacuum storage tanks, oxygen generator plant, cryogenic air separation equipment, liquefied gas vaporizers etc.

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier