Video

1 / 4

QMY6-25 walking concrete hollow block machine

Model:

- QT6-15

- QMR2-45

power:

- 36.4KW

Options:

- Cycle:40-45S

- Engine power: 5.7HP

- Weight: 215KG

- Processing: Brick Molding Machine

| Model No. : | QMY6-25 hollow block machine |

|---|---|

| Brand Name : | SIMAMIX |

| Applicable industry : | Machinery Repair Shops,Other |

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Product description

QMY6-25 Semi-auto Concrete Interlock Block Brick Making Machine

1. This equipment is mechanical hydraulic PLC controlled synthesis technique equipment. Its characteristic is high efficient, easy-operated, and easy-maintained. Block molding mainly by hydraulic, machinery as a sideline, vibrate, and press to finish molding blocks.

2. The design and manufacture of this solid brick produce line in accordance with the requirement and standard of building.

3. A high degree of automation, intelligent electronic control, the automatic process is controlled by advanced PLC(Programmable Logic Controller), input and store of process data and touch screen for blocks, it has the ideal of flexible Human Conversation Interface.

4. Good reliability, Hydraulic system preference for improved technology and perfected workmanship of design. Use an independent integrated type hydraulic station. Avoid the influence of dust and main machine vibration for the hydraulic system.

5. Good adaptability of raw material, advanced step vibration molding technology. Adjusting measures to differing conditions. Use of all kinds of waste ash and slag, reasonably reduce the dosage of cement, make many kinds of high-quality bearing or non-bearing blocks.

FEATURES

Main Machine

1. This QMY6-25 block produce line can use fly ash, slag, gangue, and other kinds of industrial residues then with sand, water, crushed stone, cement all kinds of material to make all kinds of hollow blocks, paver brick, solid bricks just changing the molds. And the percentage of the fly ash can reach 70%.

Mixing Sytem

The concrete mixer is a double-horizontal-shaft compulsory mixer. This machine has the two advantages of a stand-alone operation and a simple mixing station with the PLD series batching machine. It is a high-efficiency model with a wide range of applications.

Block Mold

The mold of the brick machine is an indispensable part of product production. Used as a model to produce various styles of bricks. The mold uses wire cutting technology to make the mold size more accurate and the cutting surface smoother. Using heat treatment and carburizing technology, the processed mold has higher hardness, more wear resistance, and longer service life.

Our Service

Pre-Sales Service:

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service:

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

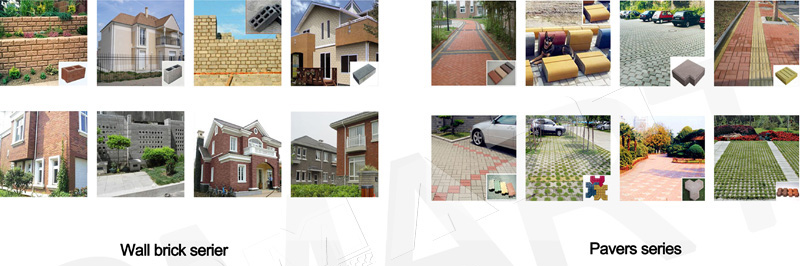

Block Application

Customer Visit

FAQ

Q: How about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. Chinese top brands or world grade brands like Siemens motors etc are equiped.

Q: How about the price?

A: As a manufactory, we can give you lower price than trade companies.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.It usually takes 1-3 days for training , 10-15 days for installation,1-2days for commission,1-2days for pre-operation.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training.It’s about 90-120 usd a day.

Q: How long it takes to do all the installation

A: It’s at most 5days processing and manufacturing for single machine,for production line,at most 15days.

Q: Can we visit your factory?

A: Yes. You can visit our factory at anytime you want.

Video

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier