1 / 3

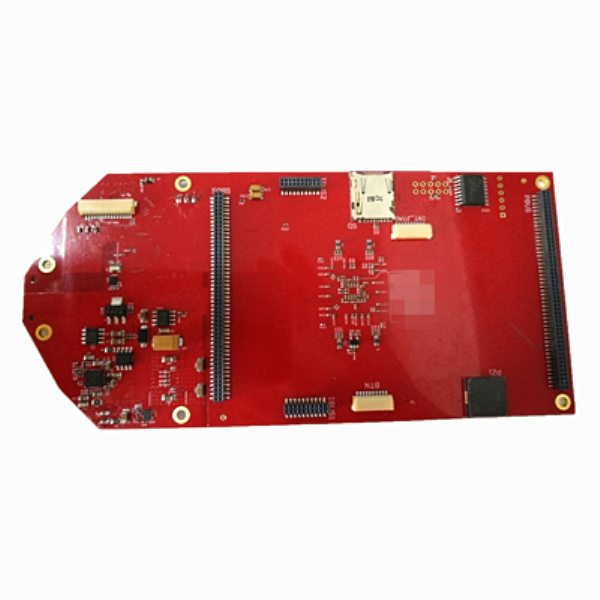

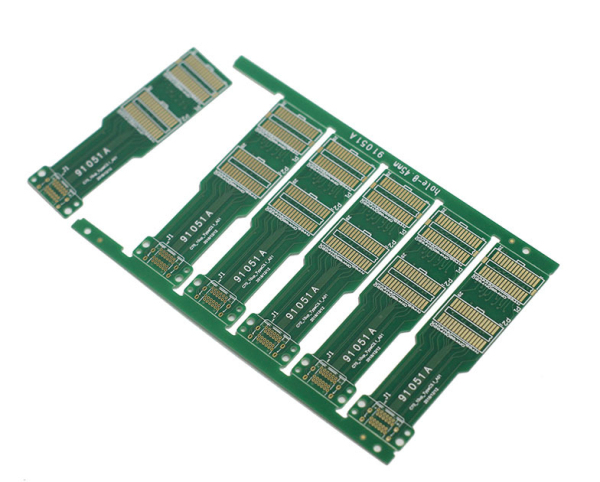

Provide gold-plated PCB heavy copper PCB

$0.36

≥1 Piece/Pieces

Options:

- Custom specifications

| Model No. : | Copper-based circuit board |

|---|---|

| place of origin : | China |

Product description

Why should the circuit board be gold-plated?

The copper layer of PCB that is not coated with solder mask is easily oxidized when exposed to the air

We know that both the front and back sides of the PCB are copper layers. In the production of PCB, no matter whether the copper layer is made by additive or subtractive methods, it will end up with a smooth and unprotected surface. Although the chemical properties of copper are not as active as aluminum, iron, magnesium, etc., in the presence of water, pure copper is easily oxidized in contact with oxygen; because oxygen and water vapor exist in the air, the surface of pure copper is exposed to air Oxidation reaction will occur soon. Because the thickness of the copper layer in the PCB is very thin, the oxidized copper will become a poor conductor of electricity, which will greatly damage the electrical performance of the entire PCB.

In order to prevent copper oxidation, to separate the soldered and non-soldered parts of the PCB during soldering, and to protect the surface of the PCB, engineers invented a special coating. This kind of paint can be easily painted on the surface of the PCB to form a protective layer with a certain thickness and block the contact between copper and air. This layer of coating is called a solder mask, and the material used is a solder mask.

When some manufacturers promote their products, they will specifically mention that their products use special processes such as gold plating and silver plating. So what is the use of this process?

The PCB surface requires soldering components, so a part of the copper layer is required to be exposed for soldering. These exposed copper layers are called pads. The pads are generally rectangular or round with a small area. In the above, we know that the copper used in the PCB is easily oxidized, so after applying the solder mask, the only thing exposed to the air is the copper on the pad.

For the exposed pads on the PCB, the copper layer is directly exposed. This part needs to be protected to prevent it from being oxidized. From this perspective, whether it is gold or silver, the purpose of the process itself is to prevent oxidation and protect the pad, so that it can ensure the yield in the subsequent soldering process.

However, the use of different metals will impose requirements on the storage time and storage conditions of the PCB used in the production plant. Therefore, PCB factories generally use vacuum plastic packaging machines to package PCBs after PCB production is completed and before delivery to customers to ensure that the PCBs are not oxidized to the greatest extent possible.

Before the final electronic components are soldered on the machine, the board card manufacturer must check the oxidation degree of the PCB once to eliminate the oxidized PCB to ensure the yield. Finally, the board card that the consumer gets has passed various tests. Even if it is used for a long time, the oxidation will almost only occur at the plug-in connection part, and it has no effect on the pad and the electronic components that have been soldered. .

We know that the biggest factor affecting heat generation is electrical resistance. The resistance is related to the material of the conductor itself, the cross-sectional area and length of the conductor. The thickness of the metal material on the surface of the pad is even far less than 0.01 mm. If the pad is processed by the OST (organic protective film) method, there will be no excess thickness at all. The resistance exhibited by such a small thickness is almost equal to 0, even impossible to calculate, and of course it will not affect the heat generation.

Send your inquiry to this supplier