1 / 1

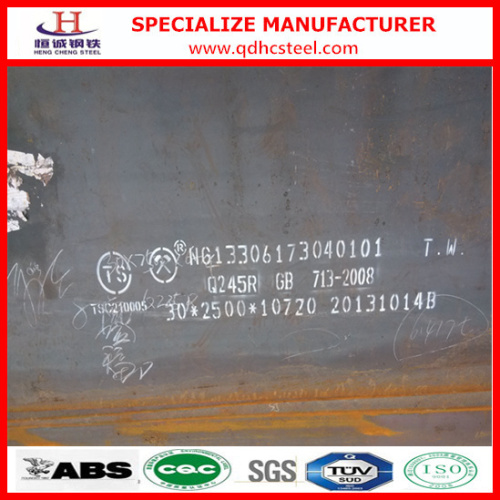

Pressure Vessel Oil and Gas Pipeline Steel Plates

Get Latest Price

Send Inquiry

| Model No. : | Pressure Vessel Oil And Gas Pipeline Steel Plates |

|---|

Qingdao Hengcheng Steel Co., Ltd.

You might also like

Product description

1. Main application

Pipeline steel was mainly used to the transferring of oil and natural gas, product oil, urban pipe coal gas coal water slurry, chemical

Engineering and construction, especially the medium of oil and natural gas transferring and urban pipe coal gas was inflammable.

Pipeline was used in certain corrosive condition, for example, marine line must resist the corrosion of seawater: The pipeline used in

Chemical industry must resist the chemical corrosion. In addition, the performance of pipeline used in cold area was more strict than that

In general condition.

2 Product characteristics

1) Steel must be clean, chemical composition stabilized:

2) The high tenacity pipeline produced by low S refining and inclusion calcium treating have high impact energy in low temperature:

3) The yield strength can be obtained by controlling the technology, in order to guarantee the stabilize of pipe.

3. Features of main equipments and processes

(1). The advanced processes including the steel-making, LF (ladle furnace) refining, VD vacuum degassing, electromagnetic stirring process have been up to the world top and this can guarantee the purity of the steel quality.

(2). The production techniques and equipments including the high precision rolling, controlled rolling and controlled cooling, wholly hydraulic straightening and automated control, automatic ultra-sonic inspection on line, automatic shearing, non-oxidizing heat treatment, roll quenching machine and the like can guarantee the high rolling precision of dimensions, good plan view pattern, flatness, surface quality and shearing quality.

(3). The finishing mill has the hydraulic AGC roller location system and CVC shape control and this can produce the plates with high performance and high quality.

(4). The maximum rolling force of the rolling mill is up to 10000 ton and can produce high strength plates with the strength class of 1200MPa. Such plates can meet the requirements of the industries of coal mine mechanical, excavators, ocean oil platform and mining cars and the like.

(5). The maximum width of the products is up to 5200mm. The maximum width in the first phase and the second are respectively up to 150mm and 400mm. The particular heavy plates and ultra-heavy plates can be manufactured in large batch with the width greater than 3200mm and the length greater than 13000mm.

(6). The maximum unit weights in the first phase and the second phase of the production line 5500mm wide are respectively 26 ton and 54 ton. The delivery can be in great unit weight.

(7). The perfect sets of facilities can realize the various condition deliveries in normal rolling condition (AR), controlled rolling and controlled cooling condition (TMCP), normalization condition (N), quenching and tempering condition (QT) and the like.

(8)...The computer can automatically mix the plates and control shearing. The thickness of the plates can be classified according to 0.1mm (it is good if the width of the ship-building plate is greater than 20mm) and the length and width can be classified according to 0.1mm. The dimension precision of the products is high, the same plate difference is small and the shape is good. This can greatly improve the material utilization.

(9)The efficient integration of the 3 production lines can realize the advantages complement. The specifications of the products are broader and the varieties are more complete.

(10)The excellent detecting equipments have formed perfect quality control system to guarantee to provide the standard and high-quality products.

Pipeline steel was mainly used to the transferring of oil and natural gas, product oil, urban pipe coal gas coal water slurry, chemical

Engineering and construction, especially the medium of oil and natural gas transferring and urban pipe coal gas was inflammable.

Pipeline was used in certain corrosive condition, for example, marine line must resist the corrosion of seawater: The pipeline used in

Chemical industry must resist the chemical corrosion. In addition, the performance of pipeline used in cold area was more strict than that

In general condition.

2 Product characteristics

1) Steel must be clean, chemical composition stabilized:

2) The high tenacity pipeline produced by low S refining and inclusion calcium treating have high impact energy in low temperature:

3) The yield strength can be obtained by controlling the technology, in order to guarantee the stabilize of pipe.

3. Features of main equipments and processes

(1). The advanced processes including the steel-making, LF (ladle furnace) refining, VD vacuum degassing, electromagnetic stirring process have been up to the world top and this can guarantee the purity of the steel quality.

(2). The production techniques and equipments including the high precision rolling, controlled rolling and controlled cooling, wholly hydraulic straightening and automated control, automatic ultra-sonic inspection on line, automatic shearing, non-oxidizing heat treatment, roll quenching machine and the like can guarantee the high rolling precision of dimensions, good plan view pattern, flatness, surface quality and shearing quality.

(3). The finishing mill has the hydraulic AGC roller location system and CVC shape control and this can produce the plates with high performance and high quality.

(4). The maximum rolling force of the rolling mill is up to 10000 ton and can produce high strength plates with the strength class of 1200MPa. Such plates can meet the requirements of the industries of coal mine mechanical, excavators, ocean oil platform and mining cars and the like.

(5). The maximum width of the products is up to 5200mm. The maximum width in the first phase and the second are respectively up to 150mm and 400mm. The particular heavy plates and ultra-heavy plates can be manufactured in large batch with the width greater than 3200mm and the length greater than 13000mm.

(6). The maximum unit weights in the first phase and the second phase of the production line 5500mm wide are respectively 26 ton and 54 ton. The delivery can be in great unit weight.

(7). The perfect sets of facilities can realize the various condition deliveries in normal rolling condition (AR), controlled rolling and controlled cooling condition (TMCP), normalization condition (N), quenching and tempering condition (QT) and the like.

(8)...The computer can automatically mix the plates and control shearing. The thickness of the plates can be classified according to 0.1mm (it is good if the width of the ship-building plate is greater than 20mm) and the length and width can be classified according to 0.1mm. The dimension precision of the products is high, the same plate difference is small and the shape is good. This can greatly improve the material utilization.

(9)The efficient integration of the 3 production lines can realize the advantages complement. The specifications of the products are broader and the varieties are more complete.

(10)The excellent detecting equipments have formed perfect quality control system to guarantee to provide the standard and high-quality products.

Send your inquiry to this supplier

Send Inquiry