1 / 1

PPGI Roof Sheet Trapezoid Roll Forming Machine

| Model No. : | C 10 |

|---|---|

| Brand Name : | QJ |

Product description

No. | PPGI Roof Sheet Trapezoid Roll Forming Machine | |

1 | Suitable material | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

2 | Thickness of coil sheet | 0.2-0.8mm |

3 | Coil width | 1250mm |

4 | Cover width | 1100mm |

5 | Material of main frame | 300H steel |

6 | Diameter of Soild shaft | 75mm, high grade 45# steel |

7 | Roller | Quenched and tempered treatment, hard chrome coated 0.05-0.07mm |

8 | Thickness of middle plate | 16mm |

9 | Forming station | 19stations |

10 | Drive type | By chain(1.0 inch) link bearing model 6210 |

11 | Power of main motor | 5.5kw with Cycloidal reducer |

12 | Power of pump station | 4kw |

13 | Forming speed | About 8-10m/min |

14 | Hydraulic cutting | Controlled by PLC |

15 | PLC | DELTA(TAIWAN)/Mitsubishi |

16 | Material of razor blades | Cr 12, quenching 58-62℃ |

17 | Frequency converter | It has the advantage of slowing down before cutting, to ensure the length accuracy(±1mm, far better than industrial standard ±3mm). |

18 | Switch | CHNT |

19 | Transducer | SAJ |

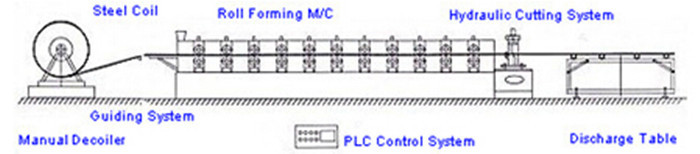

Production Flow Manual decoiling→sheet guilding→roll forming→hydraulic controlling length→automatic cutting→finished product supporting

Production Flow Manual decoiling→sheet guilding→roll forming→hydraulic controlling length→automatic cutting→finished product supporting  Packaging & Shipping Package and Loading of Cangzhou Forward Roll Forming Machine 1 Main forming machine and uncoiler is naked. 2 Tighten to container with steel wirerope and welded machine with container by angel iron. 3 PLC system and pump station are packed by waterproof plastic film. 4. Spare parts are packed by carton box

Packaging & Shipping Package and Loading of Cangzhou Forward Roll Forming Machine 1 Main forming machine and uncoiler is naked. 2 Tighten to container with steel wirerope and welded machine with container by angel iron. 3 PLC system and pump station are packed by waterproof plastic film. 4. Spare parts are packed by carton box  Production Process Roll forming machine production process

Production Process Roll forming machine production process

Accessories Spare parts ( for free) The quick-wear parts are sent to you together with the machine. chain 2pcs; hydraulic oil pipes 2 pcs; electromagnetism valves:1pc; limit switch 2 pcs; counter 1pc; relay 2 pcs; Swith 1 group.

Accessories Spare parts ( for free) The quick-wear parts are sent to you together with the machine. chain 2pcs; hydraulic oil pipes 2 pcs; electromagnetism valves:1pc; limit switch 2 pcs; counter 1pc; relay 2 pcs; Swith 1 group.  FAQ FAQ 1. Does one machine can only produce one style panel profile?

FAQ FAQ 1. Does one machine can only produce one style panel profile?Not exactly. For wider and double layer making machine. It can produce more than 6 kinds of panels. 2. How to visit your company?

A. Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you. B. Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you. 3. What can you do if the machine broken?

Our machine's warranty period is 18months, if the broken parts can't repair,we can send the new parts replace the broken parts for freel, but you need pay the express cost by yourself. If after warranty period, we can through negotiation for to solve the problems, and we supply the technical support for the whole life of the equipment. 4. Can you be responsible for transport?

Yes, please tell me the destination port or address. we have rich experience in transport. 5. How long the machine could be made?

Normally speaking, manufacture roll forming machine could be made within 45 working days. Ifyou need machines in a hurry, we can make it for you less than a month. 6. You are trade company or factory?

We are rich experience factory, enormous potentiality. Warmly welcome to visit our factory! 7. Can you accept OEM? Yes, we can accept OEM. 8. What is the payment term? Our payment term is TT, 30%TT as the deposit, before shipping pay the last 70%TT. Company Information COMPANY NAME: Cangzhou Forward Roll Forming Machinery Co.,Ltd COMPANY ADD: Fuzhuang Development Zone, 104 National Road, Botou City, Hebei Province, China

Warmly welcome you come to our factory to check machine quality at any time! Contact way Wendy QQ: 3281661235 Wechat: RonghaoZiqing Skype: QJrollformingmachine Whatsapp: 0086 15128731683

Warmly welcome you come to our factory to check machine quality at any time! Contact way Wendy QQ: 3281661235 Wechat: RonghaoZiqing Skype: QJrollformingmachine Whatsapp: 0086 15128731683 Send your inquiry to this supplier