1 / 4

Powtech 355kw 380v Vsd Variable Speed Drive Vector Control For Drawing Machines

Product description

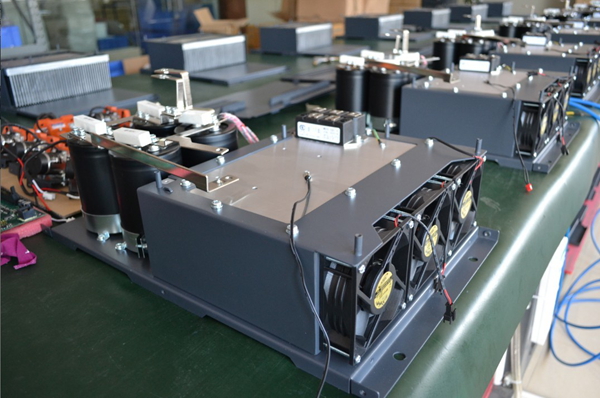

355Kw Vector Control 380V VSD Variable Speed Drive

Quick detail

The Powtech PT200 series inverter is a high-performance current vector inverter based on the European power and the latest control theoretical and technological achievements and combining with the latest market power technology application requirements, which introduces new high-performance current right amount inverter to control motor perfect by servo function for a comprehensive solution to the filed of high-end control

The Series inverter is a high-quality and multifunction vector control inverter . It can run a wide range of speed and torque control in high-precision by decoupling control of motor magnetic flux current and torque current torque :fast and accurately High-end hardware platforms, scientific production technology and complete testing equipment make the product more stable and reliable

Performance Introduction

1. Using DSP as the core of control unit to achieve high-speed high-performance control;

2. Way of speed control: SVC, VC, V/F control, torque control

3. Automatically idendtify the motor parameters, intelligent adjustment to the best control mode.

4. Deard time compensation and automatic slip compensation function, low frequency 0.25HZ can be achieved under sensorless vector control.

5. Simple PLC function can realize up to 16 segments speed and 4 segments acceleration control.

6. One key to shuttle” keyboard, swirling free, two way custom button with the demand for expansion.

7. Multi-language, humanization display menu, highlighted OLED+LED simultaneous display 3 groups of state parameters.

8. Keyboard is hot-pluggable and can store/copy 4 groups of operating parameter programs

9. Powerful communications function which can support standard to support standard RS485 and Modbus, meanwhile providing remote keyboard control.

10. Dual analog input, custom control mode, free combination of control factors

11. Short-circuit protection, more safer and more stable

12. New thermal management structure, unique duct design and thermostat heat agencies, allow the product to run more stable and longer

13. Standards EMC design to minimize pollution for power

14. All strengthened PCB coating working well in kinds of environments

Technical paramet

|

Power |

||||||

|

Voltage and frequency level |

Single-phase 200-240V,50/60HZ Three-phase 220-240V,50/60HZ Three-phase 380-415V,50/60HZ Three-phase 440-460V,50/60HZ Three-phase 575V,50/60HZ Three-phase 660V,50/60HZ Three-phase 1140V,50/60HZ |

|||||

|

Allowable fluctuations |

voltage:+-15% frequency:+-15% |

|||||

|

Control performance |

||||||

|

Control system |

DSP-based high-performance vector control inverter |

|||||

|

Output frequency |

G/P/Z/S/T/M type: 0.00-400Hz |

|||||

|

Control method |

1,open-loop magnetic flux vector control 2,PG vector control |

|||||

|

Program-runing control |

16 segments speed running |

|||||

|

Frequency accuracy |

Speed control tolerance 0.01%( (25℃±10℃)) |

|||||

|

Built-in PID |

Facilitate control closed-loop control system |

|||||

|

Starting signal |

Forward, Reverse |

|||||

|

Multi-segments speed |

Up to 16 segments speed can be set |

|||||

|

Multi-segments acceleration |

up to 4 segments acceleration can be set |

|||||

|

Emergency stop |

Interrupt controlle output |

|||||

|

Pendulum-frequency running |

Process control running |

|||||

|

Jogging |

Running slowly |

|||||

|

Output signal |

Up to 3 output signals and there 9 signal for selection. |

|||||

|

Inverter protection |

Overvoltage/undervoltage protection,current /overload /over-temperature protection |

|||||

|

IGBT temperature display |

Display present IGBT temperature |

|||||

|

RS485/RS232 |

Completely isolated RS485 communication module |

|||||

Application Field

The main application fileds: metallurgy, petroleum, chemical, textile, electric power, building materials, coal, medicine, food, paper, plastics, printing and dyeing, lifting, cable, washing, water supply, heating and ventilation, sewage treatment and other industries, machinery and equipment for: Drawing machines, blenders, cutting machine, winding machinery, compressors, air pumps, grinders, conveyors, hoist, centrifuges and various speed control machinery

Package

Send your inquiry to this supplier