Video

1 / 4

Power Tower Growing Up Turning Rolls

Options:

- HGFK-100 Fit-up Welding Rotator

| Model No. : | HGFK Fit-up Welding Rotator |

|---|---|

| Brand Name : | Zhouxiang |

| Tanks Linear Speed : | 100---1000 mm/min |

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

Hydraulic Fit-up Welding Rotator

Fit-up Welding Rotator Introduction:

Fit up welding rotator is mainly used for the butt welding of two cylinder face to face. According to different size of the work piece, there are many ways of grouping: Long shaft type for light cylinder, adjustable hydraulic type and self-adjusting hydraulic type for heavy cylinder....etc.

The heavy duty tanks fit up welding rotator absorbs the abroad advanced manufacturing experience, extremely suitable for heavy duty offshore wind tower tanks and thickness steel plate cladding or narrow gap welding.The grow up welding rotator is part of the offshore monopile welding production automation line. Together with hydraulic fit up rotator, it is using to fit up the offshore monopile & complete the joint welding. The rotator has large loading capacity, the two roller base can be moved on the machine bed and fixed by high strength bolts (8.8 grade) to suitable for the tanks with different diameter.

Fit-up Welding Rotator Technical Parameters:

|

Model |

HGFK 40 |

HGFK 60 |

HGFK 100 |

HGK 160 |

HGFK 250 |

HGFK 400 |

HGFK 500 |

HGFK 630 |

HGFK 800 |

HGFK 1000 |

HGFK 1250 |

HGFK 1600 |

||||||||||||

|

Maximum loading |

40 |

60 |

100 |

160 |

250 |

400 |

500 |

630 |

800 |

1000 |

1250 |

1600 |

||||||||||||

|

Working range |

d mm |

600 |

750 |

800 |

1000 |

1000 |

1000 |

1000 |

1000 |

1500 |

1500 |

2000 |

2000 |

|||||||||||

|

D mm |

4200 |

5000 |

6000 |

6000 |

7000 |

7500 |

8000 |

8500 |

9000 |

10000 |

15000 |

15000 |

||||||||||||

|

Rubber roller |

D1mm |

400 |

450 |

550 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|||||||||||

|

W3mm |

120 |

120 |

120 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

||||||||||||

|

Metallic roller |

D2mm |

394 |

444 |

538 |

620 |

700 |

800 |

800 |

850 |

1000 |

1000 |

1000 |

1000 |

|||||||||||

|

W4mm |

60 |

70 |

100 |

220 |

260 |

300 |

300 |

350 |

350 |

350 |

400 |

400 |

||||||||||||

|

Linear speed dm/h |

600~1200 |

|||||||||||||||||||||||

|

Speed adjusting way |

VFD |

|||||||||||||||||||||||

|

Motor power kW |

2×1.5 |

2×1.5 |

2×2.2 |

2×3 |

2×4 |

2×5.5 |

2×5.5 |

2×7.5 |

2×7.5 |

2×11 |

2×15 |

2×18.5 |

||||||||||||

|

Equipment weight kg |

2800 |

4200 |

6500 |

10500 |

14330 |

18500 |

22500 |

25000 |

32000 |

39600 |

60000 |

63000 |

||||||||||||

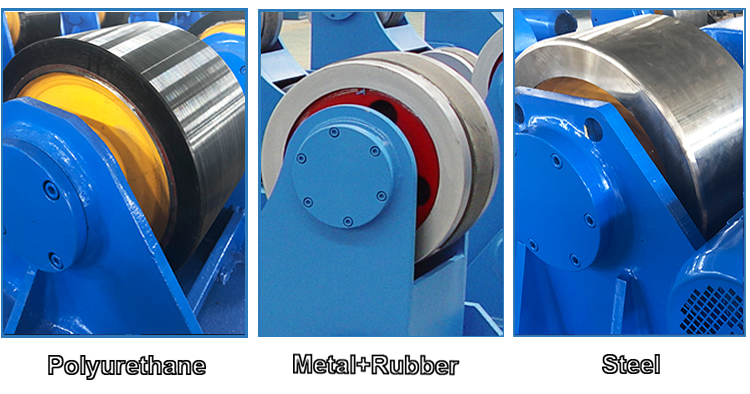

Fit-up Welding Rotator Details:

Rotator structure is firm and durable: The structural components of the rotator has carried with annealing treatment, then reprocessing after welding, which can ensure the long-term usage and service time.

Roller’s material is optional: The rollers are generally made of full PU rollers, which are wear-resistant, acid-resistant, and

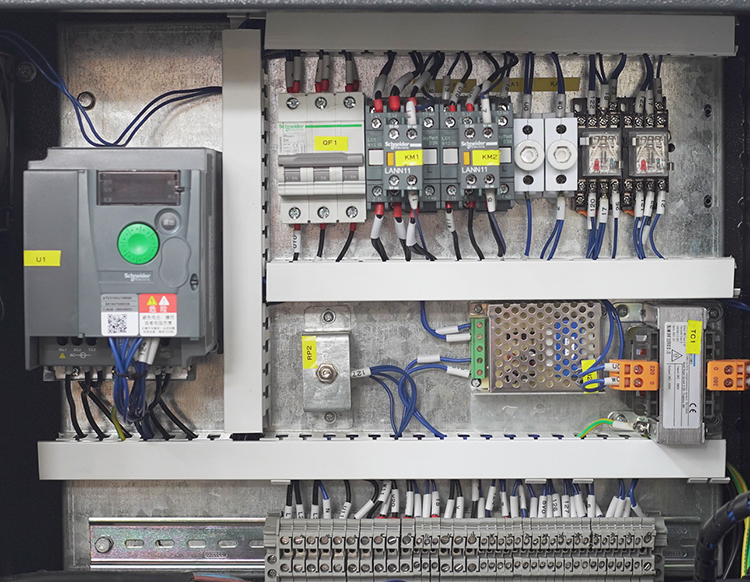

Roller speed stepless variable frequency speed control:We use Schneider inverter stepless speed regulation,which has wide speed adjusting range.

What is “Automatic Welding Center”?

Automatic welding center refers to a key welding process in similar welding components as the core, and the components required to complete the welding process are arranged and combined according to the typical process procedures of the welding process, forming the completion of the welding process. workplace. Welding center is also called welding workstation.

The welding center consists of the following parts:

1. Welding power source: welding machine, machine head, wire feeder;

2. Welding machinery and equipment: such as workpiece roller frame, welding positioner, welding manipulator;

3. Welding auxiliary machinery: such as flux pads, flux conveying and recycling devices;

4. Workpiece transmission device: including feeding, conveying and unloading mechanisms;

5. Automatic welding seam tracking and automatic adjustment device for welding wire dry elongation;

6. Integrated electrical control system.

Video

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier