1 / 1

Polyethylene PE Tape and Synthetic Primer

Get Latest Price

Send Inquiry

| Model No. : | T-100, T-200, T-300, P-00, N-00 |

|---|---|

| Brand Name : | Ningbo Ideal |

Ningbo Ideal Anti Corrosion Material Co., Ltd.

You might also like

Product description

Specifications High / Low Density Polyethylene PE Tape & Synthetic Primer for oil gas water steel pipe surface corrosion resistance and coating

1. INTRODUCTION TO PRODUCTS:

IDEAL TAPE is mainly engaged in five series of products, which are Inner Tape, Outer Tape, Joint Tape, Tape Primer, and Putty Tape with 10-odd categories in nearly 100 specifications. They can be used for the purposes of steel pipe surface corrosion resistance for various pipelines in facility projects of petroleum, petrochemical industry, city gas, oil and gas storage and transportation, power, water supply, metallurgy, civil aviation, etc.

1.1 Inner tape:

(Anticorrosion tape, Anti corrosion tape, Anticorrosive tape) is for anticorrosion of underground, underwater, & overhead pipelines.

1.2 Outer tape:

(Protection Tape, Protective Tape) is for protection of pipe and the surface of Inner Tape from damages.

1.3 Joint tape:

(Polyethylene Tape, Polyethylene Tapes, PE Tape, Rubber Tape, Butyl Tape, Butyl Rubber Tape) is for anticorrosion of field joints, fittings, & specifically piping.

Component: backing: Polyethylene PE & adhesive: butyl rubber

Thickness: 0.38mm to 1.27mm,

Width: 50mm to 300mm

Length: 30 to 300m

1.4 Tape Primer:

(Synthetic Primer) complementary product covers of the rusting steel pipe and enable to enhance the adhesive to the pipe since it is working with the adhesive of the polyethylene tape.

P19: Solid content 19%;

P27: Solid content 27%.

1.5 Putty Tape:

(Putty Filler, Mastic Tape) complementary product fills of joints / weld bead & have capability to smooth the surface of the pipe.

N99: Solid content. P-00 Primer, Paint Primer, Primer Paints Series Coating Systems AWWA C-214 Standard

2. POLYETHYLENE PE TAPE & PRIMER APPLICATIONS: Rust Removal > Priming> Inner Tape & Outer Tape Wrapping  2.1 Rust Removal Steel Surface needs treating. Its quality shall reach Sa2 or St3 grade as prescribed in GB8923-88 Pre-paint Steel Surface Rust Grade and Rust-removal Grade, and it shall be dust-free. 2.2 Priming Primer shall be stirred well before painting. An even film of primer is painted on the steel surface that is rust-removed completely and dust-free. After the primer dries up (one may feel no sticky). The steel pipe can be wrapping with tape (it usually takes 3 to 5 minutes). The primer dosage usually amounts to 80 to 100g / m2. 2.3 Inner Tape (Anti corrosion Tape) & Outer Tape (Protection Tape) Wrapping The steel pipe that is painted with primer is wrapping with tape by means of suitable devices or tools as per joint needs, and wraps the inner tape and then wraps the outer tape. Tape tensibility can be 10 to 20 N / cm. The overlapped length between beginning and end of an adhesive tape shall be no less than 1/4 circumference of the steel pipe and the total length of adhesive tape shall be no less than 100mm. each film shall be paralleled, and must not be twisted and rumpled. 3. QUALITY CONTROL QA/QC: Mechanical Test> Plastic Test> Electric Test> Chemical Analysis> Heat Aging Test

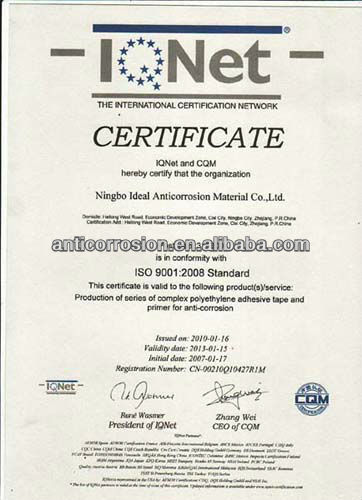

2.1 Rust Removal Steel Surface needs treating. Its quality shall reach Sa2 or St3 grade as prescribed in GB8923-88 Pre-paint Steel Surface Rust Grade and Rust-removal Grade, and it shall be dust-free. 2.2 Priming Primer shall be stirred well before painting. An even film of primer is painted on the steel surface that is rust-removed completely and dust-free. After the primer dries up (one may feel no sticky). The steel pipe can be wrapping with tape (it usually takes 3 to 5 minutes). The primer dosage usually amounts to 80 to 100g / m2. 2.3 Inner Tape (Anti corrosion Tape) & Outer Tape (Protection Tape) Wrapping The steel pipe that is painted with primer is wrapping with tape by means of suitable devices or tools as per joint needs, and wraps the inner tape and then wraps the outer tape. Tape tensibility can be 10 to 20 N / cm. The overlapped length between beginning and end of an adhesive tape shall be no less than 1/4 circumference of the steel pipe and the total length of adhesive tape shall be no less than 100mm. each film shall be paralleled, and must not be twisted and rumpled. 3. QUALITY CONTROL QA/QC: Mechanical Test> Plastic Test> Electric Test> Chemical Analysis> Heat Aging Test  4. CERTIFICATIONS: ISO9001:2008

4. CERTIFICATIONS: ISO9001:2008  5. PACKAGING: Covered Tape by Polyethylene sheet,and then loaded to carton.

5. PACKAGING: Covered Tape by Polyethylene sheet,and then loaded to carton.  Filled Primer in Plastic bottle.

Filled Primer in Plastic bottle.

1. INTRODUCTION TO PRODUCTS:

IDEAL TAPE is mainly engaged in five series of products, which are Inner Tape, Outer Tape, Joint Tape, Tape Primer, and Putty Tape with 10-odd categories in nearly 100 specifications. They can be used for the purposes of steel pipe surface corrosion resistance for various pipelines in facility projects of petroleum, petrochemical industry, city gas, oil and gas storage and transportation, power, water supply, metallurgy, civil aviation, etc.

1.1 Inner tape:

(Anticorrosion tape, Anti corrosion tape, Anticorrosive tape) is for anticorrosion of underground, underwater, & overhead pipelines.

1.2 Outer tape:

(Protection Tape, Protective Tape) is for protection of pipe and the surface of Inner Tape from damages.

1.3 Joint tape:

(Polyethylene Tape, Polyethylene Tapes, PE Tape, Rubber Tape, Butyl Tape, Butyl Rubber Tape) is for anticorrosion of field joints, fittings, & specifically piping.

Component: backing: Polyethylene PE & adhesive: butyl rubber

Thickness: 0.38mm to 1.27mm,

Width: 50mm to 300mm

Length: 30 to 300m

1.4 Tape Primer:

(Synthetic Primer) complementary product covers of the rusting steel pipe and enable to enhance the adhesive to the pipe since it is working with the adhesive of the polyethylene tape.

P19: Solid content 19%;

P27: Solid content 27%.

1.5 Putty Tape:

(Putty Filler, Mastic Tape) complementary product fills of joints / weld bead & have capability to smooth the surface of the pipe.

N99: Solid content. P-00 Primer, Paint Primer, Primer Paints Series Coating Systems AWWA C-214 Standard

Type of the Primer | P-19 | P-27 |

Base | Rubber and Synthetic Resins | Rubber and Synthetic Resins |

Solid Content | 19% | 27% |

Colour | Black | Black |

Weight / Liter | 0.79 KG | 0.81 Kg |

Flash Point | +10 oF to +50 oF, -12 oC to + 10 oC | +10 oF to +50 oF, -12 oC to + 10 oC |

Viscosity ( Time for flow 4mm nozzle over) | 10 to 20 Second | 15 to 30 Second |

2.1 Rust Removal Steel Surface needs treating. Its quality shall reach Sa2 or St3 grade as prescribed in GB8923-88 Pre-paint Steel Surface Rust Grade and Rust-removal Grade, and it shall be dust-free. 2.2 Priming Primer shall be stirred well before painting. An even film of primer is painted on the steel surface that is rust-removed completely and dust-free. After the primer dries up (one may feel no sticky). The steel pipe can be wrapping with tape (it usually takes 3 to 5 minutes). The primer dosage usually amounts to 80 to 100g / m2. 2.3 Inner Tape (Anti corrosion Tape) & Outer Tape (Protection Tape) Wrapping The steel pipe that is painted with primer is wrapping with tape by means of suitable devices or tools as per joint needs, and wraps the inner tape and then wraps the outer tape. Tape tensibility can be 10 to 20 N / cm. The overlapped length between beginning and end of an adhesive tape shall be no less than 1/4 circumference of the steel pipe and the total length of adhesive tape shall be no less than 100mm. each film shall be paralleled, and must not be twisted and rumpled. 3. QUALITY CONTROL QA/QC: Mechanical Test> Plastic Test> Electric Test> Chemical Analysis> Heat Aging Test

2.1 Rust Removal Steel Surface needs treating. Its quality shall reach Sa2 or St3 grade as prescribed in GB8923-88 Pre-paint Steel Surface Rust Grade and Rust-removal Grade, and it shall be dust-free. 2.2 Priming Primer shall be stirred well before painting. An even film of primer is painted on the steel surface that is rust-removed completely and dust-free. After the primer dries up (one may feel no sticky). The steel pipe can be wrapping with tape (it usually takes 3 to 5 minutes). The primer dosage usually amounts to 80 to 100g / m2. 2.3 Inner Tape (Anti corrosion Tape) & Outer Tape (Protection Tape) Wrapping The steel pipe that is painted with primer is wrapping with tape by means of suitable devices or tools as per joint needs, and wraps the inner tape and then wraps the outer tape. Tape tensibility can be 10 to 20 N / cm. The overlapped length between beginning and end of an adhesive tape shall be no less than 1/4 circumference of the steel pipe and the total length of adhesive tape shall be no less than 100mm. each film shall be paralleled, and must not be twisted and rumpled. 3. QUALITY CONTROL QA/QC: Mechanical Test> Plastic Test> Electric Test> Chemical Analysis> Heat Aging Test  4. CERTIFICATIONS: ISO9001:2008

4. CERTIFICATIONS: ISO9001:2008  Filled Primer in Plastic bottle.

Filled Primer in Plastic bottle.

Send your inquiry to this supplier

Send Inquiry