Video

1 / 2

Polishing Grinding Cleaning Room Dust Collection System

| Model No. : | MLWF900 |

|---|---|

| Brand Name : | Moland |

| Applicable industry : | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food &Amp; Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction Works,Energy &Amp; Mining,Food &Amp; Beverage Shops,Advertising Company |

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Product description

The key to control grinding dust is to capture and isolate the dust before it reaches the breathing zones of the operator or other nearby empolyees.

Grinding dust collection systems remove dust to prevent respiratory health effects. The grinding room dust collection system is applicable to grinding, polishing, cutting, mixing, blanking and other conditions that produce dust.

1- Integrated structure, beautiful apparance, small floor area

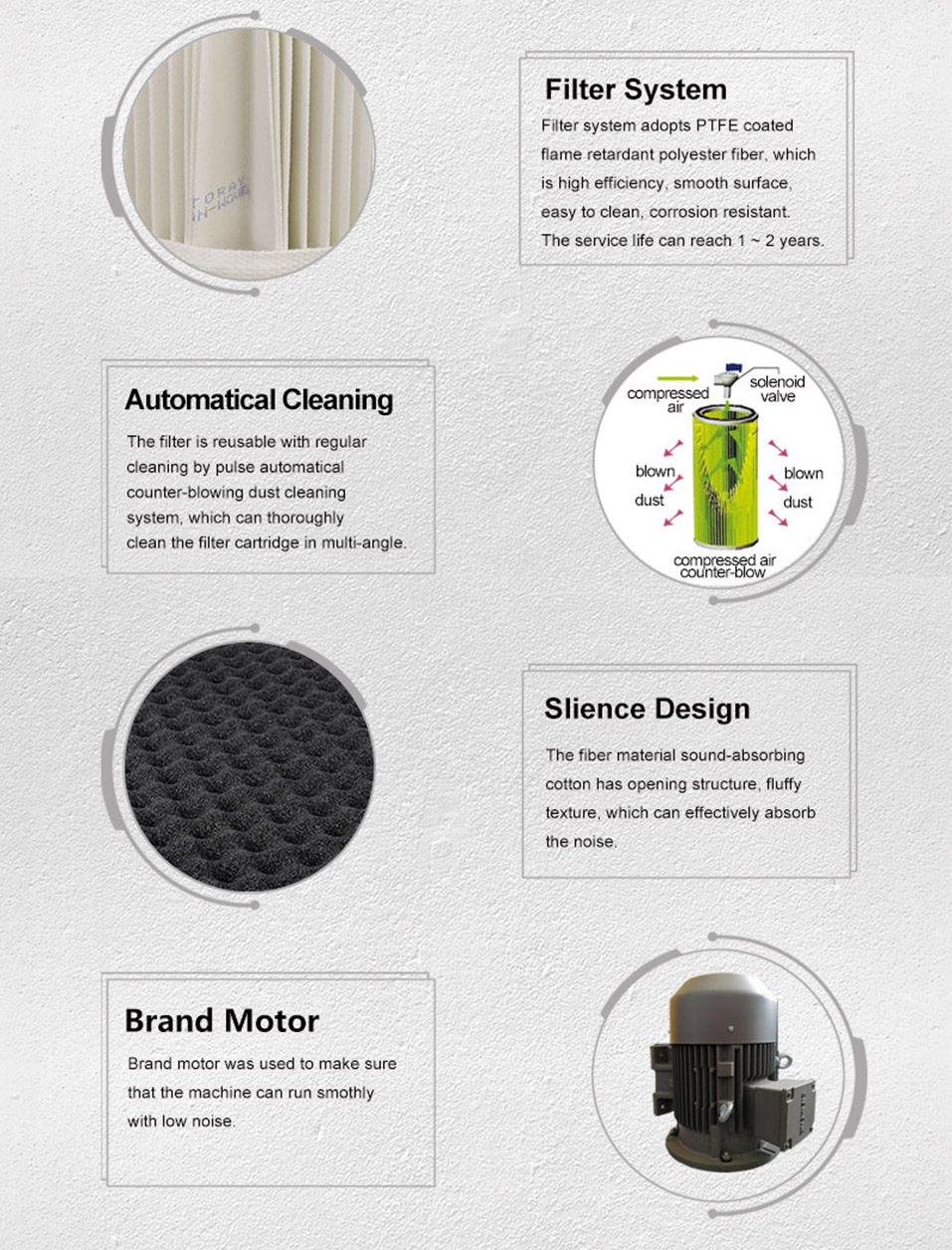

2- Anti back blowing device, fully automatic pulse back blowing and soot cleaning, make the cleaning effect more thorough.

3- Power status monitoring: alarm for over-voltage and under-voltage in case of wrong phase disconnection to prevent damage of motor and electrical parts.

4- Air pressure status monitoring: low air pressure alarm to prevent incomplete ash cleaning. The differential pressure gauge can directly display the use status of the filter element, and the automatic pulse back blowing and soot cleaning will be carried out if the differential pressure is too high.

5- Operation temperature monitoring: system over temperature alarm to prevent fire.

1- Main filter element with filter efficiency >=99.9%

2- Fault phase protection, overload protection, air pressure monitoring, temperature monitoring devices

3- Japan Toray antistatic flame retardant coated polyester fiber filter cartridge

4- PLC pulse controller

5- Explosion proof blower

6- Explosion proof solenoid valves

7- Explosion proof electric control box

8- 70L dust drawer

9- Differential pressure gauge

10- Muffler

Grinding and dedusting of large workpieces such as sheet metal and special workpieces

| Power | 3KW*2 | Double Motor, Double Control | Spare Parts List |

| Voltage | 380V 50Hz |

Siemens Motor |

Main Filter Element LX3266 Mobile Expansion Room SSF1000 Suction Hood ZK2015 Leather Curtain PL200 |

| Air Volume | 4500~9000m3/h | ||

| Max. Negative Pressure | 2500Pa | ||

| Accuracy | 0.3um |

Japan, Toray |

|

| Filtration Efficiency | 99.9% | ||

| Filtration Material | Imported flame retardant coated polyester fiber | ||

| Filtration Area | 88m2 | ||

| Filtration Size | Dia.325*660mm (8 branches) | ||

| Cleaning | Pulse back blow |

|

|

| Compressed Air | 0.5~0.6 Mpa (Oil free and water free) |

|

|

| Air Consumption | 0.3m3/ |

|

|

| Pulse Valve |

|

|

|

| Differential Pressure Switch |

|

|

|

| Noise |

|

|

|

| Size |

|

|

|

| Weight |

|

|

Video

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier