1 / 3

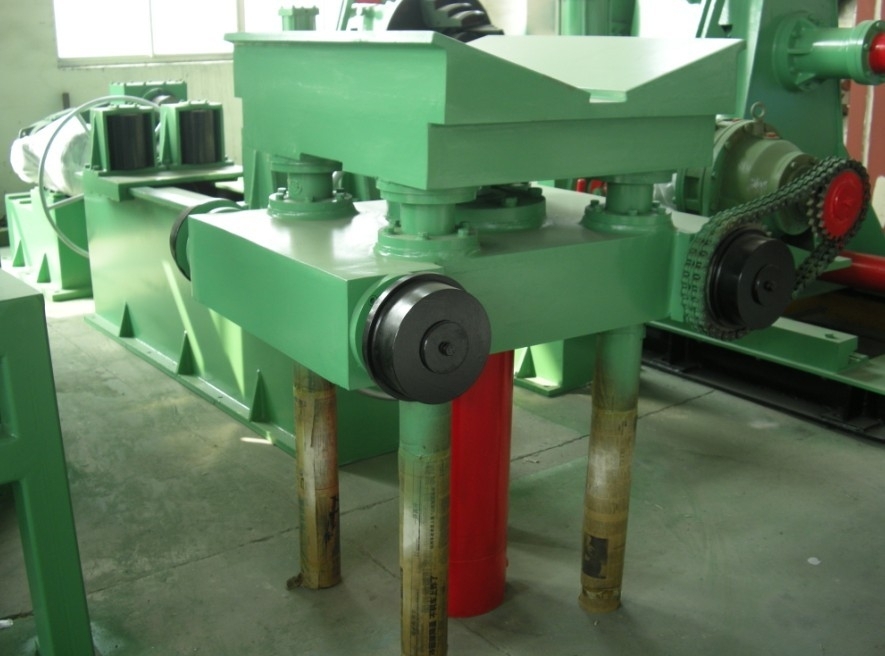

Plc High Precision Steel Coil Cut To Length Machines For Metal Processing

Product description

0.5mm~3mm×2000mm Cut-to-length Machine

Descrition:

1 V-shaped platform and coil car

1:1Form of coil car: four-wheeled walk

1.2Structure of coil car: steel structure and it is V-shape on top.

1.3Power of continuous walk:2.2kw cycloidal gear decelerator

1.4Power of lifting and lowering:hydraulic cyliner driven ф160mmx700mm

1.5max journey of lifting and lowering:700mm

1.6Max loading capacity:20000KG

1.7 walking speed:7.48m/min

2. 20T hydraulic single-head decoiler

2.1Way of decoiler:single head decoiler,hydraulic inner expansion

2.2Form of tensioning and relaxation :hydraulic oil cylinder driven,oil cyliner specification ф160mmx100mm)

2.3power of decoiling:2.2kw motor speed variable

2.4 specification of tensioning and relaxation:Φ450——Φ510.

2.5coil max outer dia:2100mm

2.6coil width:500mm--2000mm

2.7 Max loading capacity:20000kg

3.sheet guiding and sheet head straightening device,shovel head

3.1Form of sheet head guiding structure: steel made structure

3.2Form of pressing: hydraulic oil cylinder driven

3.3 motor power for sheet guiding:1.5kw

3.4hydraulic cylinder specification for sheet guiding :ф100mmx500mm

3.5hydraulic cylinder specification for sheet head straightening :ф80mmx400mm

3.6hydraulic cylinder specification for shovel head lifting &lowering:ф80mmx 350mm

3.7hydraulic cylinder specification for shoveling plate expanding&contracting :ф63mmx500mm ,1pc

4.2+ 13 rolls leveling

4.1Rolls form:2 pinch rolls for feeding

4.2 specifications of pinch rolls;ф125mmx2000mm

4.4 form of connection:coupling,upper rolls with passively and lower rolls with main drive

4.5 Leveling roll material GCr15,heat processment,HRC58--60

4.6 levelling rolls specifications:ф125mmx2000mm

4.7Levelling power:45KW DC motor,distributor and joint coupling

4.8Levelling speed:0--50m/min

5:coil storage pit/loop

5.1 Pit size:3mx1.8mx3m(LXWXH) made by the customer on the base

5.2The main Function is the coil storage and as well as to protect the coil against damage on the ground

6:sides guiding device

6.1Adjustable width:300mm---2000mm

6.2Roller processment:HRC50--54

63Vertical rolls :4pcs

6.4 manual adjustment

- second-time precision levelling machine

7.1 Leveling roll material GCr15 or 9Cr2Mo heat processment,HRC58--60

7.2 levelling rolls specifications:ф65mmx2000mm

7.3Levelling power:21KW servo- motor made in Germany ,distributor and joint coupling

- sheet film covering machine

8.1 Its function is to composite the protection paper onto the sheet and protect the Aluminium sheet surface against damage or scratch

9.sheet Shearing machine

9.1Max shearing width;2000mm

9.2shearing thickness:1-5mm

9.3Shearing accuracy:≤±0.50mm/2m

9.4shearing machine power:7.5kw

9.5 working journey:74 times per minute

9.6 cutting blade material:6CrW2Si

10:sheet transmissioing table

10.1It is consist of transmissioning rolls,transmissioning belt and machine frame.

10.2power:2.2kw

11 Pneumatic stacker

11.1 form of stacking:pneumatic

11.2Side pneumatic cyliner specification:100x200mm,2pcs

11.3Horizontal pneumatic cyliner specification:100x200mm,2pcs

11.4 power;3-1.5kw

12;hydraulic lifting&lowering stacker,discharging table

12.1max stacking weight:5T

12.2Max stacking height:≤350mm

12.3Stacking length:1000mm----3000mm

12.4 stacking power.2kw

12.5its function of the stacker is to transport the sheet into the discharging table

12.6sheet discharging table

12.7power;2.2kw

12.8 its function is to take the stacked sheet outside for packing and transportation

13.hydraulic control system and pneumatic control system

13.1.1hydraulic system is made up of hydraulic stations and accessory parts.The main valves is from Taiwan brand

13.2It can supply all machines hydraulic oil and cylinder pressure

13.3Power: 4--7.5kw

13.4rated pressure:12Mpa

13.5Flowing volume:32L/min

13.6 tank volume:400L

13.7hydraulic oil available: 46#

13.8Oil temperature:-5---70°C

13.9pneumatic control system

13.10 Using pressure:0.6Mpa

13.11Volume:1L

13.12All of the pneumatic parts are made in China and from famous brand

14 electrical control system

14.1.1Power supply:380V,50Hz or design according to the customer local standard

14.2PLC control is Simens brand and human-interrative touch screen from Taiwan to realize the whole line control

14.3 we adopts motor made in china's famous brand on the shearing part and leveling machine part

14.4 First-timeLeveling machine is DC motor control system with imported Euroasia DC control system

14.5we adopts servo motor control system,made in German Lenzn on second-time precision leveling machine part

14.6 we adopt the servo-motor on the shearing machine with Lenzn brand made in Germany

14.7we adopt the touch screen to adjust the machine speed, sheet qty and sheet length

14.8 Mail electrical parts are from Schneider brand

13.the buyer's preparing item lists:

13.1the whole power supply and switches

13.2 the total wires and lines

13.3 lubricant oil and hydraulic oil

13.4 rails for coil car

13.5 worktable materials

13.6 the layout direction will be from the left to right

3.documents

The seller will offer the machines lines instruction,production diagram and hydraulic theory drawing and electrical drawing when shipping the container

4.gurantee:

12 months after commissioning and installing in the buyer s factory and the standard of the machines belongs to national standard and qualified according to national standard

Applications:

Specifications:

Basic specification of the whole line:

Basic specifications of the Steel coil:galvanized steel,stainless steel, Aluminium

Coil thickness:0.4--5mm

Coil width:800mm---2000mm

Coil weight:max 20T

coil outer diameter: max2100mm

Coil inner diameter:φ480---φ508

Cutting length:500mm---4000mm

Cutting length tolerance:+/-0.5mm according to the length 2000mm

Cutting diagonal tolerance:+/-1.0mm according to the length 2000mm

Leveling accuracy:≤±1.5mm/m2

Line speed:≤50mm/min

Cutting speed:1--13pieces according to the length 2500mm

Total power;120kw

The dimension of the whole line:30mx8mx3m(LXWxH)

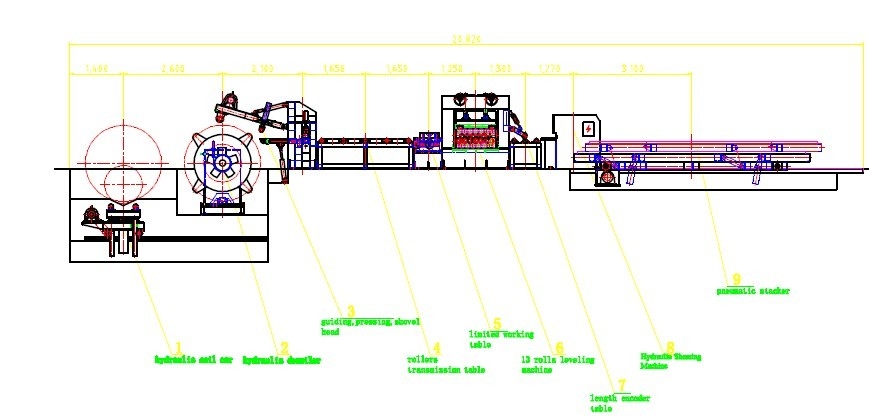

Components of 0.4mm---5mm x 2000mm leveling&cut-to-length machine

|

Hydraulic coil car(20T) |

1 |

|

Hydraqulic coil car(20T) |

1 |

|

V-shaped coil storage platform |

1 |

|

guiding&pressing and shovel head unit, |

1 |

|

Guiding unit No 1 |

|

|

First-time leveling rolls machine(13 rolls) |

1 |

|

Coil storage pit |

1 |

|

Guiding units No 2 |

1 |

|

Second-time precision levelling machine(23 rolls) |

1 |

|

Film covering unit |

1 |

|

High-speed mechanical Shearing machine |

1 |

|

Sheet transmission table |

1 |

|

Sheet pushing unit(pneumatic auto-stacker |

1 |

|

Hydraulic lifting&lowering table |

1 |

|

Sheet discharging table |

1 |

|

Hydraulic control cabinet |

1 set |

|

Pneumatic control system |

1 set |

|

Electrical control cabinets |

1 set |

Flowchart:

Hydraqulic coil car--hydraulic single head decoiler--guiding&pressing and shovel head unit--sides guiding organ---13 rolls levelling--coil storage pit--guiding No 2-- Precision levelling(23 rolls)---film covering unit---shearing machine---sheet transmission table------sheet pushing units(pneumatic stacker)---hydraulic lifting&lowering stacker --sheet discharging table ----hydraulic control system and electrical control cabinets

Send your inquiry to this supplier