1 / 6

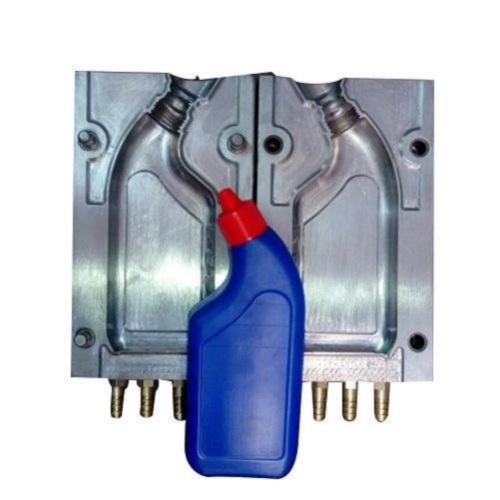

Plastic water bottle injection mold Blowing mold

$7000.00

≥1 Set/Sets

Options:

- AS PER CUSTOMER DESIGN

| Model No. : | CT-10858 |

|---|---|

| Brand Name : | Ceeto |

| place of origin : | China |

Ningbo, Zhejiang, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Product description

Ceeto Mold has rich experience to design

high quality plastic injection molds, our company service scope refers to Plastic

Injection Mould, Injection Molding Automotive Parts including Automotive

Interior Plastic Injection Mould and Automotive Exterior Plastic Injection

Mould. As well as Home Appliance Injection Mould, Daily Commodity Injection

Mould etc.

Blow molding of PET Bottle Mould, We are specialized in developing new bottle blow moulds, sample bottle measuring and all kinds of plastic water bottle blow moulds, design, and machining. All bottle blow moulds supplied with uniform dimensions and mirror finished cavity. Some blow moulds are made to fit kinds of blowing machinery which are one-stage or two-stage. The moulds are widely used for mineral water, carbonate, juice and not filling package. We can also help customers for their factory or production line design.

When preparing a custom blow molding procedure, manufacturers must decide on a few different things, mainly: the material they will use, the blow molding process they will use and the shape of the mold cavity. The decisions they make depend entirely on the client application specifications and requirements. For example, if the product requires strong compaction resistance, they will likely consider a material like polysulfone.

While blow molded products come in an assortment of standard shapes and sizes, there are some products that are used for special applications and must be made via custom blow molding. Blow molding service providers routinely craft custom molds so that you can receive the most well-tailored product possible. To make sure you are on the same page, they will first create a prototype to share with you. If there is something you don`t like, you can discuss it before they`ve gone into full production.

Plastic Bottle Blow Mould Basic Information

- Mold cavity: Single cavity

- Size : 2L- 10L

- Method of making preforms: Extrusion Type

- Design software: AutoCAD, UG, Pro-E etc.

- Plastic material: PE

- Mold standard component: HASCO

- Applications: Bottle, Jars, Jerry Cans, Gallons, Containers

- Mold material: S50C, P20,S136,2316,Aluminium

- Steel treatment: HRC 40-45

- Cooling system: separate cooling system

- Mold life: min.2 million shots

- Delivery time: 40-45 working days

- Transportation package: Wooden box

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger×

Ningbo, Zhejiang, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier