1 / 3

plastic injection mould tooling manufacturing

| Model No. : | 20150511 |

|---|---|

| Brand Name : | Yuanhai |

Product description

Mold Specifications General specifications:

Mold Specifications General specifications: TECHNICAL SPECIFICATIONS | ||

Type of mould | Injection mould | Small,medium,large mold |

Mold Material | S136, P20, 718H , 2738 , NAK80 ,1.2311 etc | |

Nr of Cavities | 1+1,1+2+1,2+2,4+4,Single or mutilcativies | |

Cycle time | 10-30seconds | |

Injection machine | 90-1000ton | |

Life span of mold | 300k-1000k | |

Shrinkage | ||

Product Material | PE , PP, HDPE , PPR , PVC , PP , PS , PET , ABS , PC , etc | |

Injection Type | Hot Runner | QTY of Drops |

| Cold Runner | Hot sprue,Sequential Injection |

Gate Point | Edge gate, Pin point gate, Sub gates, Fan gate, bayer | |

Surface finish | Tech polish, High gloss, Texture,VDI 3400 | |

Mould hot treatment | Tempering , Quending , Nitriding | |

Main Processing Equipment | Sodick, Seiki, CNC , high speed carve , EDM ,wire cut , drill | |

Tooling Workshop

Tooling Workshop

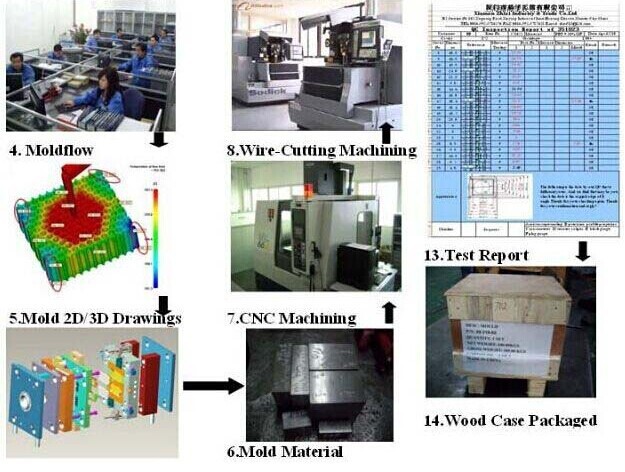

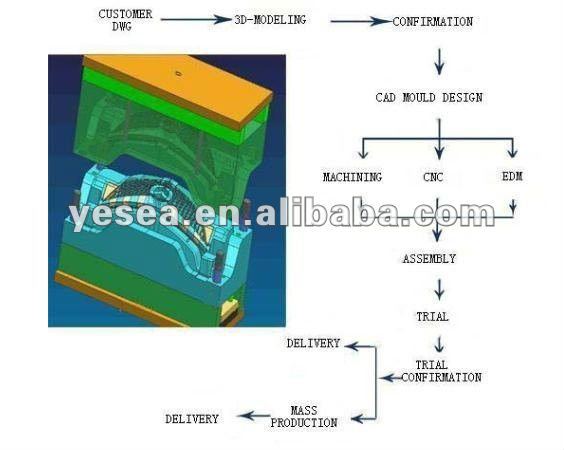

Mould Making Step

Mould Making Step

Advantages of YH 1.Competitive price. 2.Continuance service and support. 3.Diversified rich experienced skilled workers. 4.Custom R&D program coordination. 5.Application expertise. 6.Quality,reliability and long product life. 7.Mature,perfect and excellent ,but simple design. 8.Good after-service 9.Punctual delivery time Packaging & Shipping Package Moulding Parts Inner Packing:Pack in Wrap bag or Paper Box Outer Packing:Strong Carton Plastic Mould Inner Packing:Pack in Wrap bag Outer Packing:Wooden Pallet Our Package is strong enough for sea ,inland shipping and air As Per customer Request Payment Terms Shipping Porting :Shanghai China T1(First Testing) Sample :25 Days more or less Leading Time:35 Days around Payment Method:30% for deposit by T/T ,40% for first Testing ,the balanced paid before shipping,L/C,Western Union ,MoneyGram ,etc . After Sales Service Pls contact us in team after you receive the moulds Tel:0086-21-67679181 Fax:0086-21-57670797

Advantages of YH 1.Competitive price. 2.Continuance service and support. 3.Diversified rich experienced skilled workers. 4.Custom R&D program coordination. 5.Application expertise. 6.Quality,reliability and long product life. 7.Mature,perfect and excellent ,but simple design. 8.Good after-service 9.Punctual delivery time Packaging & Shipping Package Moulding Parts Inner Packing:Pack in Wrap bag or Paper Box Outer Packing:Strong Carton Plastic Mould Inner Packing:Pack in Wrap bag Outer Packing:Wooden Pallet Our Package is strong enough for sea ,inland shipping and air As Per customer Request Payment Terms Shipping Porting :Shanghai China T1(First Testing) Sample :25 Days more or less Leading Time:35 Days around Payment Method:30% for deposit by T/T ,40% for first Testing ,the balanced paid before shipping,L/C,Western Union ,MoneyGram ,etc . After Sales Service Pls contact us in team after you receive the moulds Tel:0086-21-67679181 Fax:0086-21-57670797

Send your inquiry to this supplier