1 / 1

Plastic Injection Mould for Infusion Regulator

Get Latest Price

Send Inquiry

Best Hope Mold & Plastic Co., Ltd

You might also like

Product description

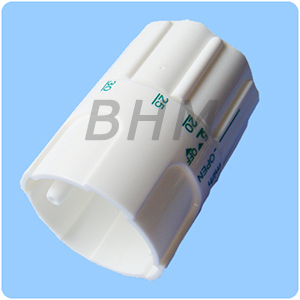

Injection Mould of Plastic Infusion Regulator/Infusion Set Mold

BEST HOPE MOLD & PLASTIC CO., LTD. Is a hign precision plastic injection mold maker and molded plastic products manufacturer, dedicated to providing constructive and innovative solutiong for the benifit of our client.

We BHM facility, including high speed milling machine, EDM, WEDM and CMM optimize the tooling process and improve accuracy and efficiency of each client's moulds, to ensure customer can get high-quality molds and products.

Our company has obtained ISO9001: 2008 quality management certification.

And both our molds and products meet the standard of Europe and America.

We can custom mould for auto plastic parts manufacturing, like bumper, lamp, guard, etc.

As well as the plastic part injection is what we can do.

(1)This product is used in regulation and the flow control in vein infusion;

(2)Mainly, it can carry out regulation at the right moment according to condition and medicine needs, makes infusion more scientific and accurate;

(3)The treatment effect that has raised medicine has reduced the medicine occurence rate of side effect greatly;

(4)Making medical worker free oneself from traditional sheet rely on the original operation method of visual examination and the adjusting control of by hand;

(5)Product safety is reliable, operating and simple is applied extensively in vein infusion field, is clinical to modemize to have offered more safe reliable tool.

We are looking forward to hearing from you.

BEST HOPE MOLD & PLASTIC CO., LTD. Is a hign precision plastic injection mold maker and molded plastic products manufacturer, dedicated to providing constructive and innovative solutiong for the benifit of our client.

We BHM facility, including high speed milling machine, EDM, WEDM and CMM optimize the tooling process and improve accuracy and efficiency of each client's moulds, to ensure customer can get high-quality molds and products.

Our company has obtained ISO9001: 2008 quality management certification.

And both our molds and products meet the standard of Europe and America.

We can custom mould for auto plastic parts manufacturing, like bumper, lamp, guard, etc.

As well as the plastic part injection is what we can do.

(1)This product is used in regulation and the flow control in vein infusion;

(2)Mainly, it can carry out regulation at the right moment according to condition and medicine needs, makes infusion more scientific and accurate;

(3)The treatment effect that has raised medicine has reduced the medicine occurence rate of side effect greatly;

(4)Making medical worker free oneself from traditional sheet rely on the original operation method of visual examination and the adjusting control of by hand;

(5)Product safety is reliable, operating and simple is applied extensively in vein infusion field, is clinical to modemize to have offered more safe reliable tool.

We are looking forward to hearing from you.

|

Brief work procedures |

1. We can do based on your 2D/3D drawings or original samples 2. We have 23 engineers responsible for parts design and tooling, drawings can be sent to you with 2-3 days. 3. When advance payment received and drawings confirm, we start molds tooling 4. Normally 35 days later, we do mold test, check samples and improve molds 5. T1 mold test samples will be sent to customer 6. Customer confirm samples, if prepare molds shipment or do mass production of plastic parts |

| What we can guarantee |

1. Competitive labor cost will bring you whole project cost down. 2. High precision tooling and fresh material using can meet the same quality level as Europe and USA. 3. Our high efficiency will be good assistance for your finish products and launch to market earlier than others! For custom making products, Confidential Agreement is always we will comply with. |

Send your inquiry to this supplier

Send Inquiry