1 / 1

Plastic Injection Molding Machine Part

Get Latest Price

Send Inquiry

| Model No. : | Plastic Injection Molding Machine Part |

|---|---|

| Brand Name : | Splendor |

Shenzhen Splendor Technology Co., Ltd.

You might also like

Product description

General Information of Plastic Injection Molding Machine Part :

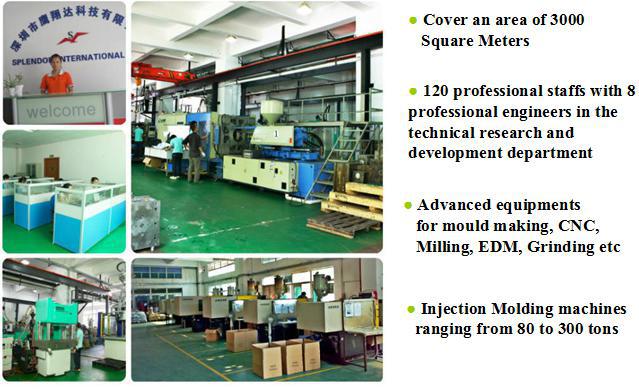

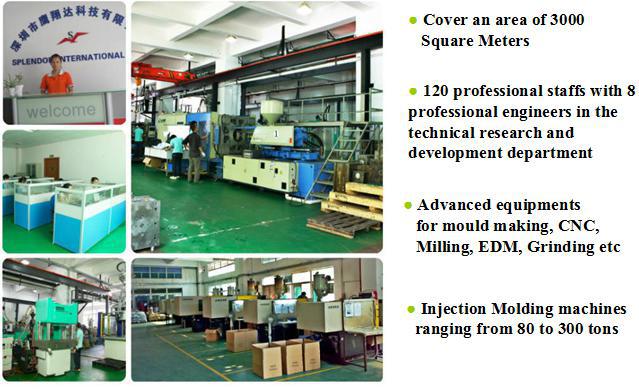

Follow us to visit our facotry:Cooperation with direct manufacturer for cost saving and high qulity 1. Company Landscape  2. Workshop:

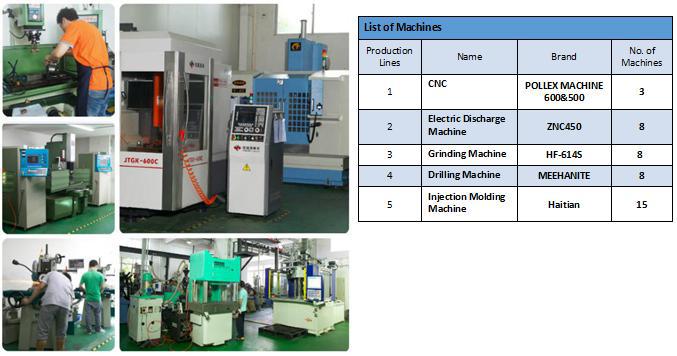

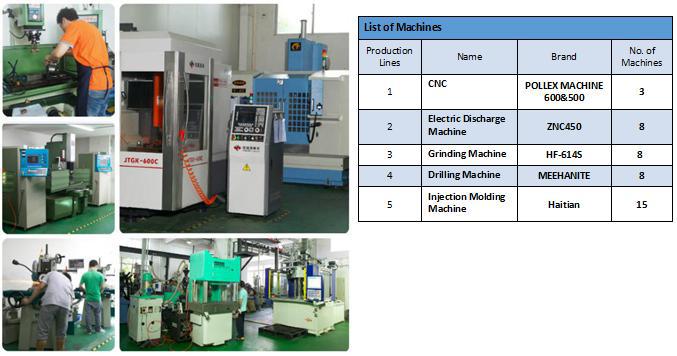

2. Workshop:  3. Machines

3. Machines  4. Product System We have complete cost control system and carry out strict "supply chain management systems”, manufacture management systems, quality management systems, logistics management systems and design management systems. We strive to reduce the cost for our clients

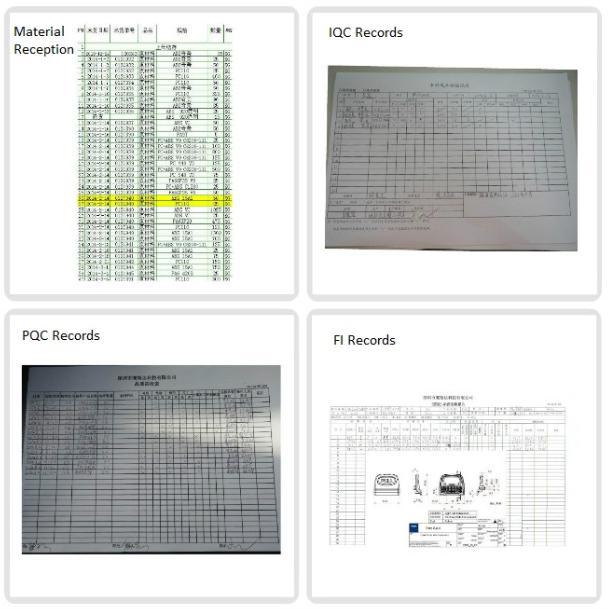

4. Product System We have complete cost control system and carry out strict "supply chain management systems”, manufacture management systems, quality management systems, logistics management systems and design management systems. We strive to reduce the cost for our clients  41 Incoming Inspections : Material Reception, Incoming Quality Check (IQC) Records , Production Quality Check (PQC) records, and Final Inspection (FI) records are availiable

41 Incoming Inspections : Material Reception, Incoming Quality Check (IQC) Records , Production Quality Check (PQC) records, and Final Inspection (FI) records are availiable  4.2 Manufacturing Process

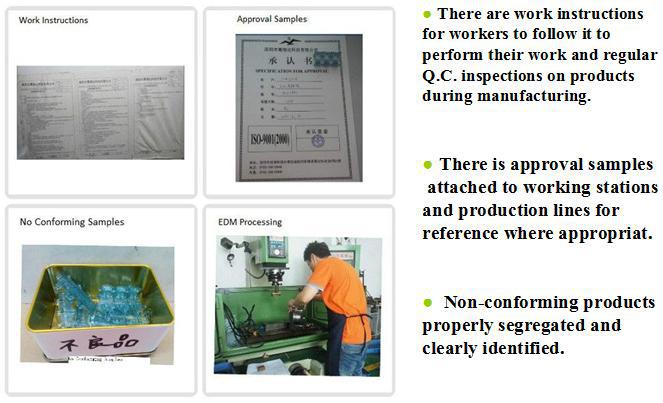

4.2 Manufacturing Process  4.3 Quality Management: • There are 2 QC Managers to head the Quality Control function. • Quality Manual for workers to keep high quality in mind • There is a developed quality control plan showing inspection procedures

4.3 Quality Management: • There are 2 QC Managers to head the Quality Control function. • Quality Manual for workers to keep high quality in mind • There is a developed quality control plan showing inspection procedures

used during manufacturing 4.4.Final Inspection and QA Testing • There are adequate instructions available for inspectors to follow for final inspection • Inspection & Testing are performed on products before packing and final inspection before shipment.

4.4.Final Inspection and QA Testing • There are adequate instructions available for inspectors to follow for final inspection • Inspection & Testing are performed on products before packing and final inspection before shipment.  4.5 Warehouse

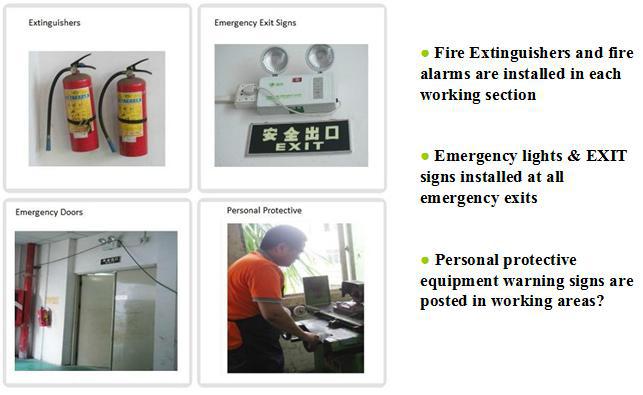

4.5 Warehouse 4.6 Emergency Facilities

4.6 Emergency Facilities  5. Our Customers: Our Splendor have many customers in Russia,USA,UK, Canada, Greece,Turkey etc. We are the top supplier of TEXA, SST, Pyronix for more than ten years. As we always satisfied our customers with high quality, superior service and punctual delivery, we have gained good reputation from them

5. Our Customers: Our Splendor have many customers in Russia,USA,UK, Canada, Greece,Turkey etc. We are the top supplier of TEXA, SST, Pyronix for more than ten years. As we always satisfied our customers with high quality, superior service and punctual delivery, we have gained good reputation from them  6. Exhibition: Mould Eurasia 2012 in Turkey ; ROSMOULD 2013 & 2014 in Russia

6. Exhibition: Mould Eurasia 2012 in Turkey ; ROSMOULD 2013 & 2014 in Russia  7. We will participate in NPE 2015 & Rosmould 2015 & Plast 2015 Exhibition

7. We will participate in NPE 2015 & Rosmould 2015 & Plast 2015 Exhibition  8. Product Shows

8. Product Shows

| 1 | Mould base material | LKM, HASCO, LOCAL ,DME, etc |

| 2 | Mould core material | 718H, S136H, NAK80 , P20, etc |

| 3 | Plastic molded parts material | ABS, ABS+PC, PC, PP, PVC, |

| 4 | Cavity | Single, Multi |

| 5 | Runner | Hot & Cold Runner |

| 6 | Gate | Pin-point gate, Edge gate |

| 7 | Finish | Semi-Matt, Polish |

| 8 | Design software | Pro-E, IGES, UG, CAD CAXA, ect |

| 9 | Main processing equipment | CNC, Cutting, Carved, Milling, EDM |

| 10 | Arrangement type | I-section, Straight body mould |

| 11 | Second Processing | Silk-scree Printing, Plating, Painting |

| 12 | Package | Wooden case for Plastic injection mold , carton box for Plastic Injection Molding Machine Part |

| 13 | Delivery time | 30-40 days for mould and samples of Plastic injection mold, 7days for mass production of Plastic Injection Molding Machine Part |

| 14 | Trade Term | Ex-works, FOB Shenzhen, CIF |

| 15 | Payment Term | Payment by T/T |

2. Workshop:

2. Workshop:  3. Machines

3. Machines  4. Product System We have complete cost control system and carry out strict "supply chain management systems”, manufacture management systems, quality management systems, logistics management systems and design management systems. We strive to reduce the cost for our clients

4. Product System We have complete cost control system and carry out strict "supply chain management systems”, manufacture management systems, quality management systems, logistics management systems and design management systems. We strive to reduce the cost for our clients  41 Incoming Inspections : Material Reception, Incoming Quality Check (IQC) Records , Production Quality Check (PQC) records, and Final Inspection (FI) records are availiable

41 Incoming Inspections : Material Reception, Incoming Quality Check (IQC) Records , Production Quality Check (PQC) records, and Final Inspection (FI) records are availiable  4.2 Manufacturing Process

4.2 Manufacturing Process  4.3 Quality Management: • There are 2 QC Managers to head the Quality Control function. • Quality Manual for workers to keep high quality in mind • There is a developed quality control plan showing inspection procedures

4.3 Quality Management: • There are 2 QC Managers to head the Quality Control function. • Quality Manual for workers to keep high quality in mind • There is a developed quality control plan showing inspection proceduresused during manufacturing

4.4.Final Inspection and QA Testing • There are adequate instructions available for inspectors to follow for final inspection • Inspection & Testing are performed on products before packing and final inspection before shipment.

4.4.Final Inspection and QA Testing • There are adequate instructions available for inspectors to follow for final inspection • Inspection & Testing are performed on products before packing and final inspection before shipment.  4.5 Warehouse

4.5 Warehouse 4.6 Emergency Facilities

4.6 Emergency Facilities  5. Our Customers: Our Splendor have many customers in Russia,USA,UK, Canada, Greece,Turkey etc. We are the top supplier of TEXA, SST, Pyronix for more than ten years. As we always satisfied our customers with high quality, superior service and punctual delivery, we have gained good reputation from them

5. Our Customers: Our Splendor have many customers in Russia,USA,UK, Canada, Greece,Turkey etc. We are the top supplier of TEXA, SST, Pyronix for more than ten years. As we always satisfied our customers with high quality, superior service and punctual delivery, we have gained good reputation from them  6. Exhibition: Mould Eurasia 2012 in Turkey ; ROSMOULD 2013 & 2014 in Russia

6. Exhibition: Mould Eurasia 2012 in Turkey ; ROSMOULD 2013 & 2014 in Russia  7. We will participate in NPE 2015 & Rosmould 2015 & Plast 2015 Exhibition

7. We will participate in NPE 2015 & Rosmould 2015 & Plast 2015 Exhibition  8. Product Shows

8. Product Shows

Send your inquiry to this supplier

Send Inquiry