1 / 1

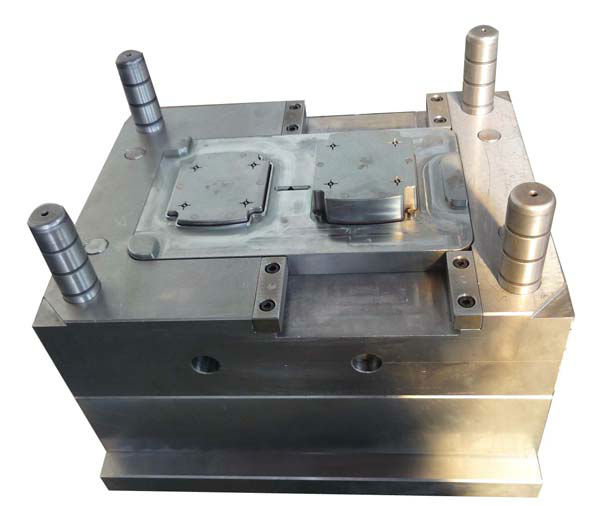

plastic injeciton mold molds plastic manufacturer

| Model No. : | YH20140106 |

|---|---|

| Brand Name : | Yuanhai |

Product description

1.ISO9001

2.OEM/ODM

3.Precision:0.001

4.Cherry Yamaha Lipton supplie

molds plastic maker Product Description

Name | molds plastic |

Mould material | P20, 718, NAK80, S136, SKD11, 8407, 1.2363 or customers' appointed material |

mould base | LKM, HASCO etc. |

Cavity | Single / Multiple |

Runner | Hot / cold runner |

Design software | UG, ProE, CAD |

Plastic material | ABS, AS, PPS, PP, POM, PC, PA, PMMA, PS, HDPE, TPE, TPU, TPR and other customer appointed material. |

Mould Life | 500000 shots – 2000000 shots |

Mould processing | Using advanced equipment for the molds, including digital control CNC (computer manufacturing center), EDM (electric-spark machine), several line cutting machines, multi-function milling machines etc. |

Packing | Wooden Case |

Specification | According to customer’s requirements or the requirements agreed detailed on the contract. |

Plastic tool box injection mould

Plastic tool box injection mould  Plastic the letter C injection moulds

Plastic the letter C injection moulds  plastic injection auto parts mold photos:

plastic injection auto parts mold photos:

Plastic injection storage box molding

Plastic injection storage box molding  Plastic injection sensor box mould

Plastic injection sensor box mould Mannequin Blowing molds

Mannequin Blowing molds

Company Information Shanghai Yuanhai Plastic Mould Co., Ltd. is located in Songjiang District of Shanghai and our factory covers an area of one thousand square meters. We are strong in technology and specialized in plastic, die casting, rubber mold design and manufacture.

Company Information Shanghai Yuanhai Plastic Mould Co., Ltd. is located in Songjiang District of Shanghai and our factory covers an area of one thousand square meters. We are strong in technology and specialized in plastic, die casting, rubber mold design and manufacture. After nearly a decade of development, we now have more than forty staff members including 25 mold technicians and 9 mold modeling and product design engineers. In particular, our company adopts 3D laser scanners to aid in product development and mold design engineering departments.

We have our own complete moulding design centre. The CNC and CAD/CAM capacity and processing equipment have been qualified to ensure high quality products, Our company consistently insists on development depending on trustworthiness, existence depending on quality, scientific research depending on development, benefits depending on management.

We have our own mold tooling workshop,specialize in OEM service. 1 Our strength: a) Advanced R&D technic b) Strict Inspection; c)Timely delivery time d) Excellent Service. e) spray painting,printing etc. f) assembly and art package Our team:

The injection workshop:

The injection workshop:

Our Services Engineering capabilities include: R&D products Prototype design and product assembly Mould design Hot runner design Cold runner design Packaging & Shipping 1.Wooden case for mold 2.Carton for plastic product 3.According to customers` requirement FAQ FAQ About Plastic Mould Manufacturing Q1: What kind of molds do you make? Plastic injection mold, Compression mold or something else? A1: We are mainly making plastic mold injection and rubber compression mold. Sometimes we also make die casting molds according to our customer’s requirements. Q2: Do you build hot runner plastic moulds? A2: Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as DME,Master,Mastip,Hasco,Yudo,Incoe,Husky,etc. The manifold recommended for your tool is selected to meet your individual needs. Q3: What types of files do you accept (drawings)? A3: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc. Q4: What kind of steel do you use for plastic mouldings? A4: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, NAK80, H13, S136, DIN 1.2738, etc. Q5: Can you provide the steel certificate and heat-treatment certificate? A5: Yes, We can provide steel certificate or hardness certificate to prove. Q6: Can you make the texture / text / heat-treatment /nitriding for the inejction mold plastic? A6: Yes, As plastic mold fatory, we have long-term cooperated subsidiary factories that do those processes. They are professional and well reputed in our local market. Q7: How long is the lead-time for a plastic injection mold? A7: It all depends on the mold’s size and complexity.Normally, the lead time is 25—45days. If the Plastic Mouldings are very simple and not big size, we can work out within 20 days. Q8: Do you make spare parts for your customer? A8: Yes, we will provide spare parts for the mold if needed or required by client. Q9: How do you pack the china plastic moulds? A9: We pack the plastic moulds with wooden box. There are the main 3 operation steps. First Step: We daub some rust preventive oil on the mold. Second step: We pack the mold with thin plastic film to avoid moisture. Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any movement. FAQ About Molded Products Q10: How many injection plastic mouldings machines do you have? A10: We have 40 sets of plastic Injection Mouldings machines. Q11: what is the minimum & maximum unit weight and size your machines can produce? A11: Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. Q12: What kind of plastic materials you usually use? A12: We are specialized in producing plastic products with the following materials: PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on. Q13: How do you pack the plastic molded parts? A13: We pack the plastic molded parts by thick-wall cartons. If the finish surface of plastic molded parts requires safe protection to avoid scratches, we will use bubble plastic bag to pack the parts. FAQ About Worldwide Delivery Q14: Can you deliver the plastic moulds or plastic products to our factory?

Our Services Engineering capabilities include: R&D products Prototype design and product assembly Mould design Hot runner design Cold runner design Packaging & Shipping 1.Wooden case for mold 2.Carton for plastic product 3.According to customers` requirement FAQ FAQ About Plastic Mould Manufacturing Q1: What kind of molds do you make? Plastic injection mold, Compression mold or something else? A1: We are mainly making plastic mold injection and rubber compression mold. Sometimes we also make die casting molds according to our customer’s requirements. Q2: Do you build hot runner plastic moulds? A2: Yes. We build hot runner Plastic Moulds and specialized in many different systems, such as DME,Master,Mastip,Hasco,Yudo,Incoe,Husky,etc. The manifold recommended for your tool is selected to meet your individual needs. Q3: What types of files do you accept (drawings)? A3: With our CAD systems we can accept following files: STP, IGS, DXF, DWG, Cad Key PPT, STL, X_T, CATIA, UG files, etc. Q4: What kind of steel do you use for plastic mouldings? A4: We can use any type of steel appointed by customer or popular in the market. Such as P20, 718, NAK80, H13, S136, DIN 1.2738, etc. Q5: Can you provide the steel certificate and heat-treatment certificate? A5: Yes, We can provide steel certificate or hardness certificate to prove. Q6: Can you make the texture / text / heat-treatment /nitriding for the inejction mold plastic? A6: Yes, As plastic mold fatory, we have long-term cooperated subsidiary factories that do those processes. They are professional and well reputed in our local market. Q7: How long is the lead-time for a plastic injection mold? A7: It all depends on the mold’s size and complexity.Normally, the lead time is 25—45days. If the Plastic Mouldings are very simple and not big size, we can work out within 20 days. Q8: Do you make spare parts for your customer? A8: Yes, we will provide spare parts for the mold if needed or required by client. Q9: How do you pack the china plastic moulds? A9: We pack the plastic moulds with wooden box. There are the main 3 operation steps. First Step: We daub some rust preventive oil on the mold. Second step: We pack the mold with thin plastic film to avoid moisture. Third step: We put this plastic film packed mold in a wooden box, and fix it avoid any movement. FAQ About Molded Products Q10: How many injection plastic mouldings machines do you have? A10: We have 40 sets of plastic Injection Mouldings machines. Q11: what is the minimum & maximum unit weight and size your machines can produce? A11: Our machines produce the unit parts from 1 gram to 6000 grams weight. Our machines can produce the maximum size of unit plastic part: 1.5*1.5*1.5 meters. Q12: What kind of plastic materials you usually use? A12: We are specialized in producing plastic products with the following materials: PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on. Q13: How do you pack the plastic molded parts? A13: We pack the plastic molded parts by thick-wall cartons. If the finish surface of plastic molded parts requires safe protection to avoid scratches, we will use bubble plastic bag to pack the parts. FAQ About Worldwide Delivery Q14: Can you deliver the plastic moulds or plastic products to our factory? A14: Yes, We have cooperated with many international logistics companies for years. And we have full experience to manage the delivery directly to the client's factory or appointed warehouse. Contact information Contact person:Ms.Ellen Zhao Skype: hongyan1442 Tel:+86-21-67679181 Fax:+86-21-57670797 Address: 1#Plant ,62 Lane 2185 Jiasong zhong Road Huaxin Town Qingpu Shanghai China

Send your inquiry to this supplier