1 / 3

Plastic Granulating Machine for Plastic Recycling

| Brand Name : | LANGBO |

|---|---|

| place of origin : | China |

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

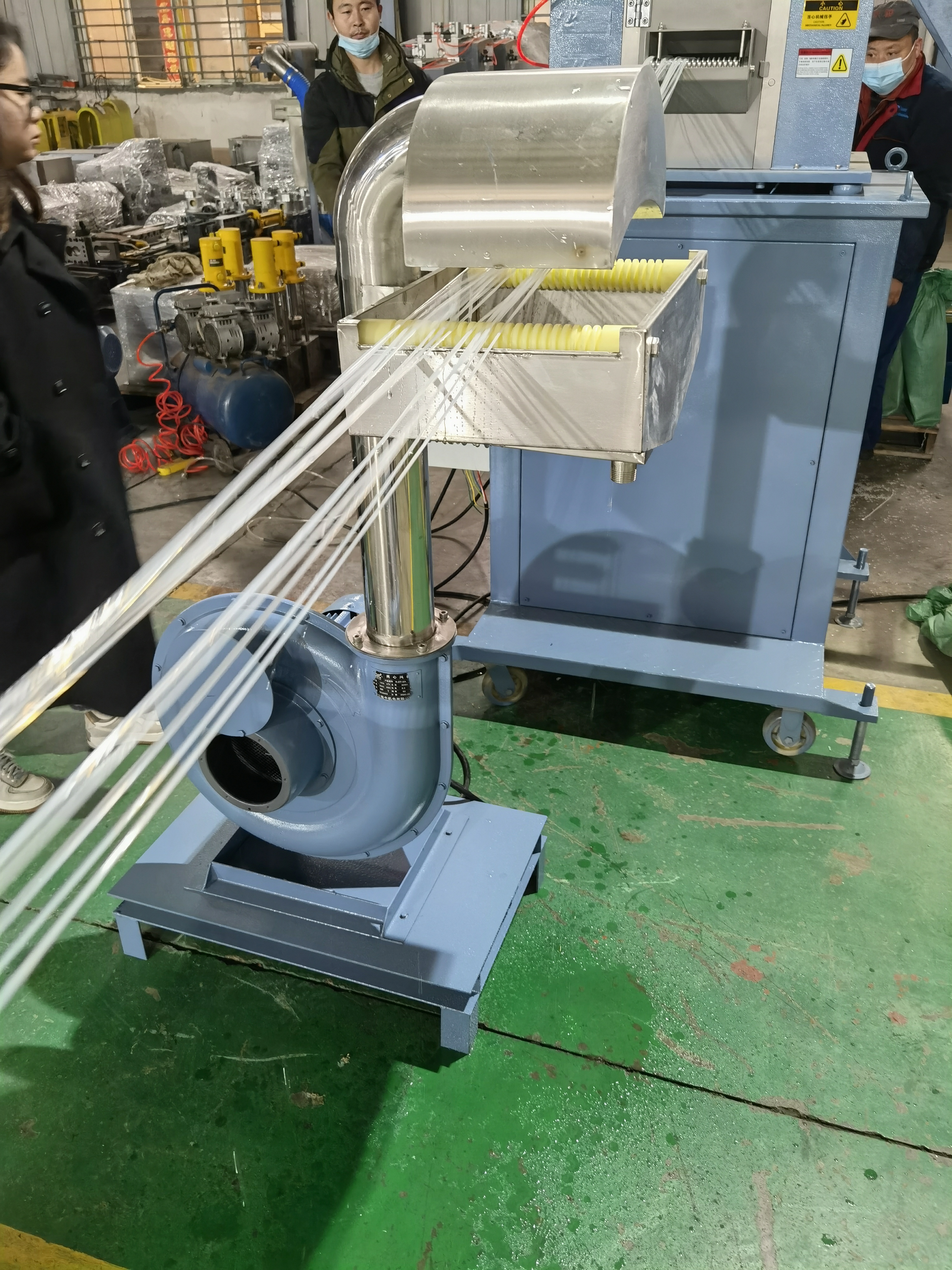

Plastic Granulating Machine for Plastic Recycling

INTRODUCTION:

The processing granulation is usually used in plastic compounding and recycling. Concerning the plastic compounding, it means that the mixing of two or more components in an extruder produce a new product. During compounding, the virgin resins will be shaped with certain desired character by adding ingredients. And the plastic with new character will be extruded and granulated into pellets for storage and further application. As for the plastic granulating line, the processed post-industry and post-customer plastic will be melted, extruded and granulated into pellets, which are convenient for storage and further application. In general, the crushed or shredder plastic flakes which have been washed and cleaned have bad feeding efficiency for extruding, so the plastic granulating line for recycling is necessary.

STRAND PELLETIZING PROCESS DESCRIPTION:t

In plastic pelletizing process, the application of granulating equipment highly increases the efficiency and guarantees the high-quality of products. The detailed process is as following:

The molten polymer flows into the strand die which looks like a sheet die, and the material exits the die through multiple holes. Each hole shapes the material into polymer strand. The strands will be firstly cooled in water bath or trough, then dried by a de-watering unit or air knife, finally fed into a strand pelletizer, where they are cut into pellets. This pelletizing concept can also be called as "dry cut". In general, strand pelletizing is cutting the polymer into pellets after cooled and solidified which is convenient for storage and further application.

FEATURE OF MACHINE FROM LANGBO:

1. High strength and elastic coefficient, high impact strength and wide temperature range;

2. High transparency and free dyeing.

3. Low shrinkage and good size stability.

4. Poor fatigue resistance.

5. Good weather resistance.

6. Excellent electrical characteristics.

7. Odorless and odorless are harmless to human health.

8. Machine design lower consumption and noise, easy and safe operation.

9. ABB, RKC, OMRON, SIEMENS brand

10. 1-year warranty time

CONTACT US

The customized extrusion and strands pelletizing system should fit the pace of the whole recycling line. We are looking for providing you our professional suggestions around the strand pelletizing system even around the whole production solution.

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier